Preparation method of graphene oxide nanofiltration membrane with adjustable flux

A technology of graphene and nanofiltration membranes, applied in chemical instruments and methods, membrane technology, semi-permeable membrane separation, etc., can solve the problems of increased energy consumption and cost, complicated preparation process, increased resistance, etc., and achieve high water flux and rejection rate, simple preparation method, and controllable spacing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

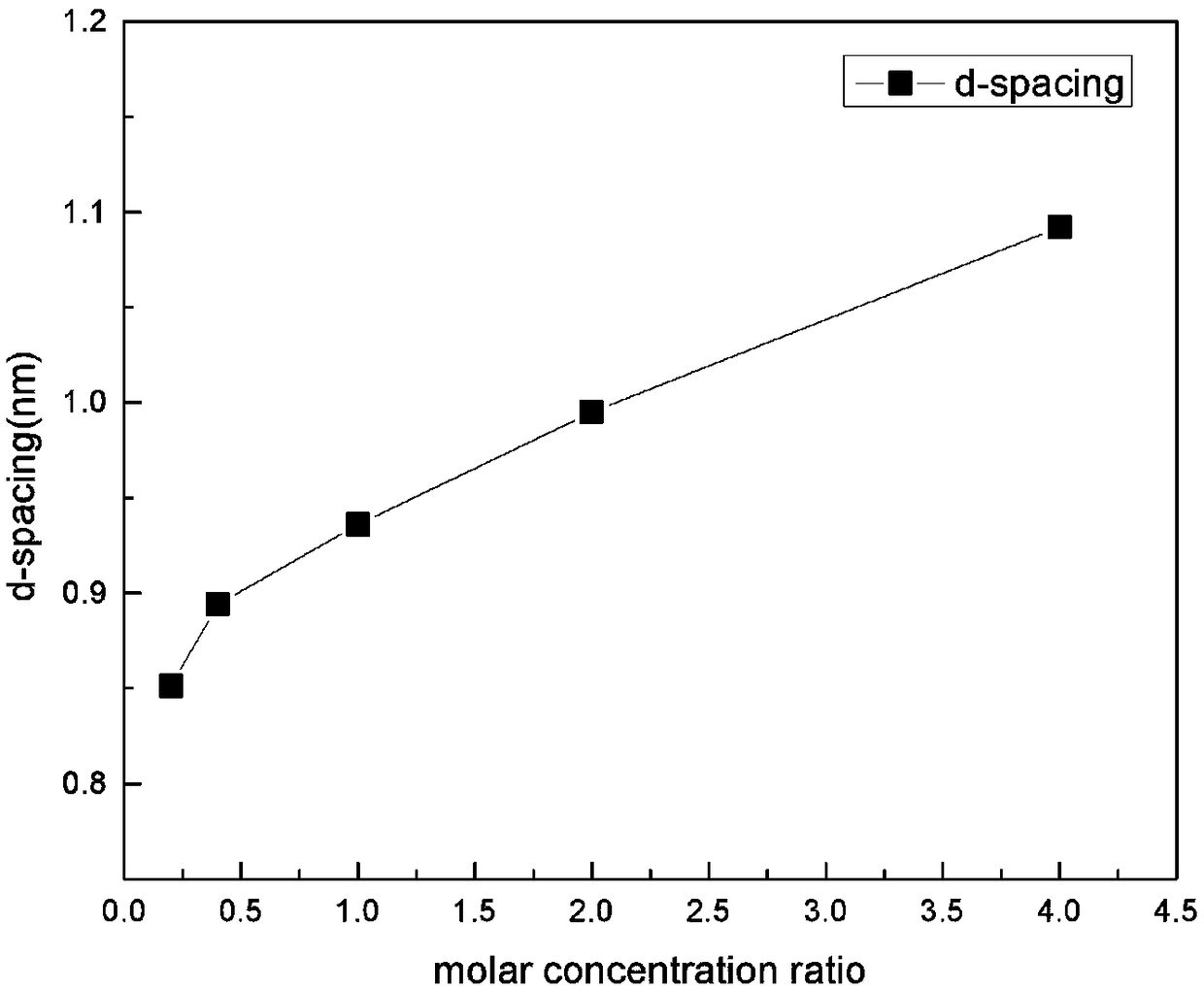

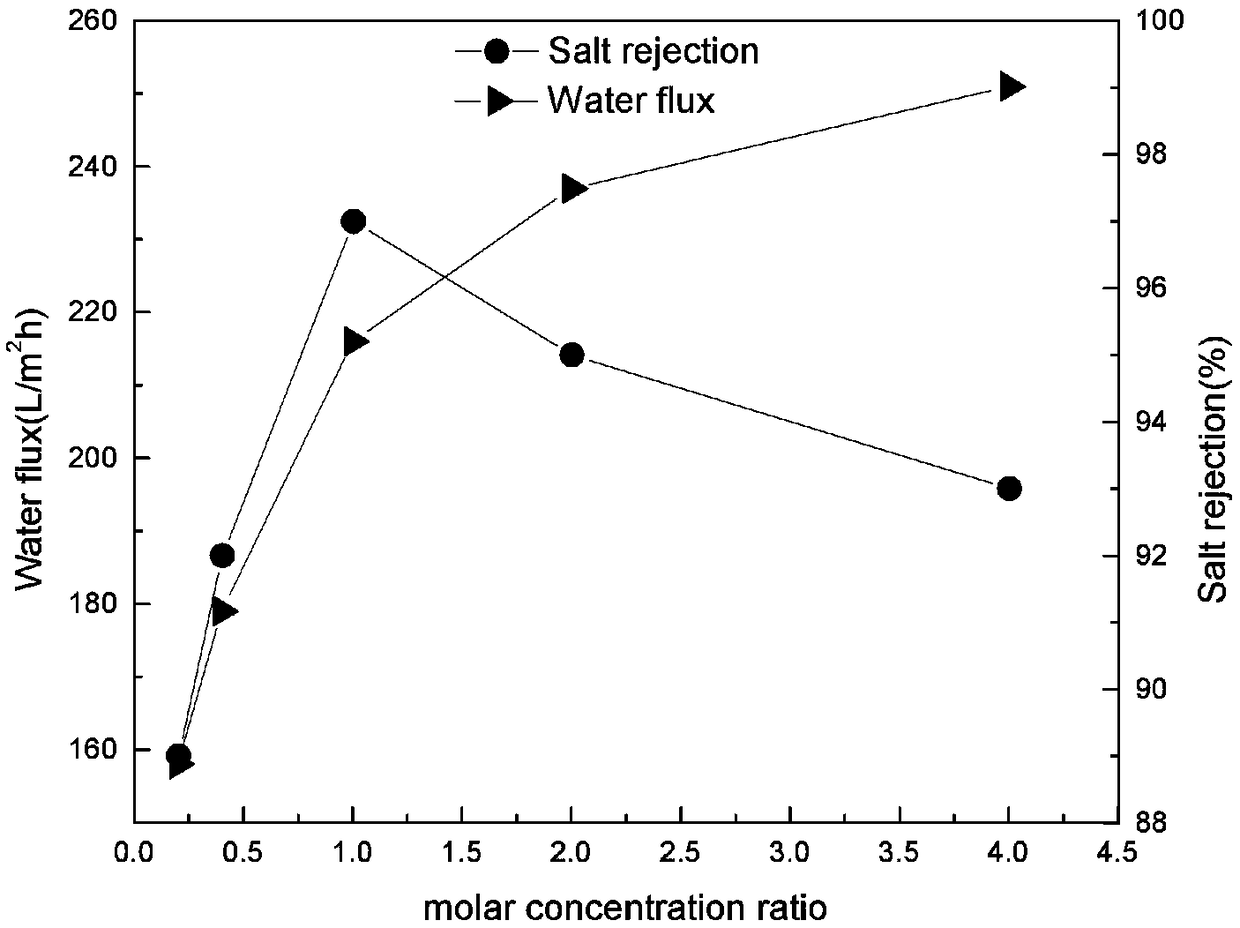

[0024] Graphene oxide was prepared by the improved Hummers method, and the prepared graphene oxide was centrifuged and washed 4 times at 6250 rpm to obtain a graphene oxide aqueous solution with a concentration of 10 mg / mL, which was ultrasonically treated for 7 minutes. Take 0.5mL of the prepared graphene oxide aqueous solution in a 50mL volumetric flask, add 1mL of 1mol L -1 Aqueous solution of ethylenediamine, dilute to 50mL with deionized water, the molar concentration of ethylenediamine in the mixed solution is 0.02mol L -1 . After ultrasonic treatment, vacuum filtration was performed, and the composite membrane was self-assembled by auxiliary pressure vacuum, washed with ultrapure water for 5 times and then dried. Soak the composite membrane in 20mL 0.1mol·L -1 In the n-hexane solution of trimesoyl chloride (TMC), take it out after 30 min, wash with n-hexane for 5 times, and dry at room temperature to obtain the modified graphene oxide composite film. The molar concen...

Embodiment 2

[0026] Graphene oxide was prepared by the improved Hummers method, and the prepared graphene oxide was centrifuged and washed 4 times at 6250 rpm to obtain a graphene oxide aqueous solution with a concentration of 10 mg / mL, which was ultrasonically treated for 7 minutes. Take 0.5mL of the prepared graphene oxide aqueous solution in a 50mL volumetric flask, add 2mL of 1mol L -1 Aqueous solution of ethylenediamine, dilute to 50mL with deionized water, the molar concentration of ethylenediamine in the mixed solution is 0.02mol L -1 . After ultrasonic treatment, vacuum filtration was performed, and the composite membrane was self-assembled by auxiliary pressure vacuum, washed with ultrapure water for 5 times and then dried. Soak the composite membrane in 20mL 0.1mol·L -1 In the n-hexane solution of trimesoyl chloride (TMC), take it out after 30 min, wash with n-hexane for 5 times, and dry at room temperature to obtain the modified graphene oxide composite film. The molar concen...

Embodiment 3

[0028] Graphene oxide was prepared by the improved Hummers method, and the prepared graphene oxide was centrifuged and washed 4 times at 6250 rpm to obtain a graphene oxide aqueous solution with a concentration of 10 mg / mL, which was ultrasonically treated for 7 minutes. Take 0.5mL of the prepared graphene oxide aqueous solution in a 50mL volumetric flask, add 5mL of 1mol·L -1 Aqueous solution of ethylenediamine, dilute to 50mL with deionized water, the molar concentration of ethylenediamine in the mixed solution is 0.1mol L -1 . After ultrasonic treatment, vacuum filtration was performed, and the composite membrane was self-assembled by auxiliary pressure vacuum, washed with ultrapure water for 5 times and then dried. Soak the composite membrane in 20mL 0.1mol·L -1 In the n-hexane solution of trimesoyl chloride (TMC), take it out after 30 min, wash with n-hexane for 5 times, and dry at room temperature to obtain the modified graphene oxide composite film. The molar concent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com