Boron-doped microporous silicon dioxide film as well as preparation method and application thereof

A silicon dioxide membrane and silicon dioxide technology, applied in the field of membrane separation, can solve the problems of low salt rejection rate, low permeation flux, poor stability, etc., and achieve the effect of improving desalination performance, simple preparation process, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] (1) Mix 7.71 mL of 1,2-bis(triethoxysilyl)ethane (BTESE) and 1.75 mL of triethyl borate (TEB) into 156 mL of absolute ethanol, and stir vigorously at room temperature for 4 hours , and then add dropwise a mixed solution of 0.45mL 65-68% concentrated nitric acid and 16.2mL deionized water under stirring conditions, and continue stirring at room temperature for 15 hours to obtain a non-metallic boron-doped silica sol. The sol formulation ratio is Si:B:H + :H2 O=1:0.25:0.165:22.5 (molar ratio).

[0026] (2) The boron-doped silica sol prepared in step (1) was diluted 3 times with absolute ethanol, and then the tubular Al with an average pore diameter of 100 nm 2 o 3 Dip the porous carrier into the diluted sol for 30 seconds, dry it in a constant temperature and humidity box for 12 hours, and finally heat it up to 300°C in an air atmosphere in a muffle furnace and bake it for 3 hours, with a temperature rise / fall rate of 0.5°C min -1 .

[0027] (3) After repeating the ab...

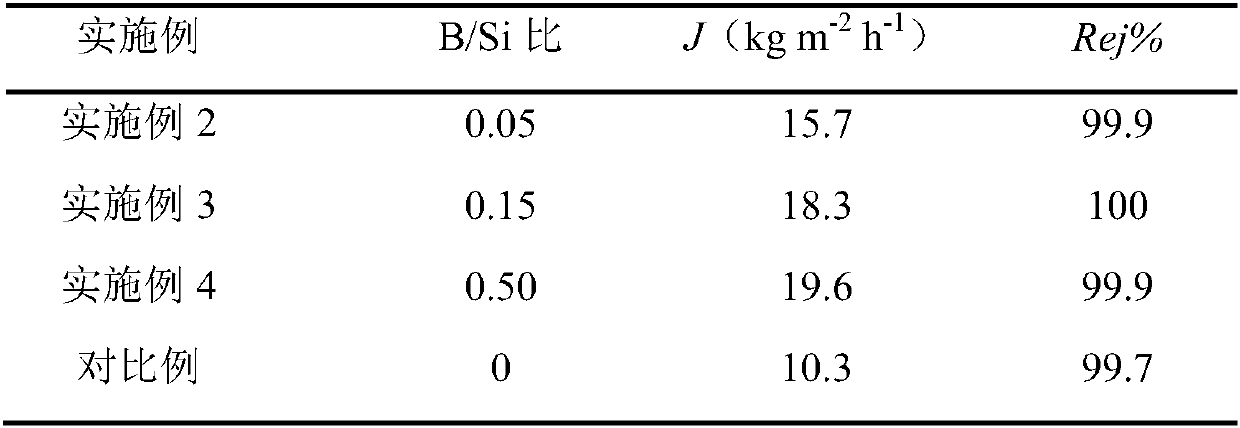

Embodiment 2-4

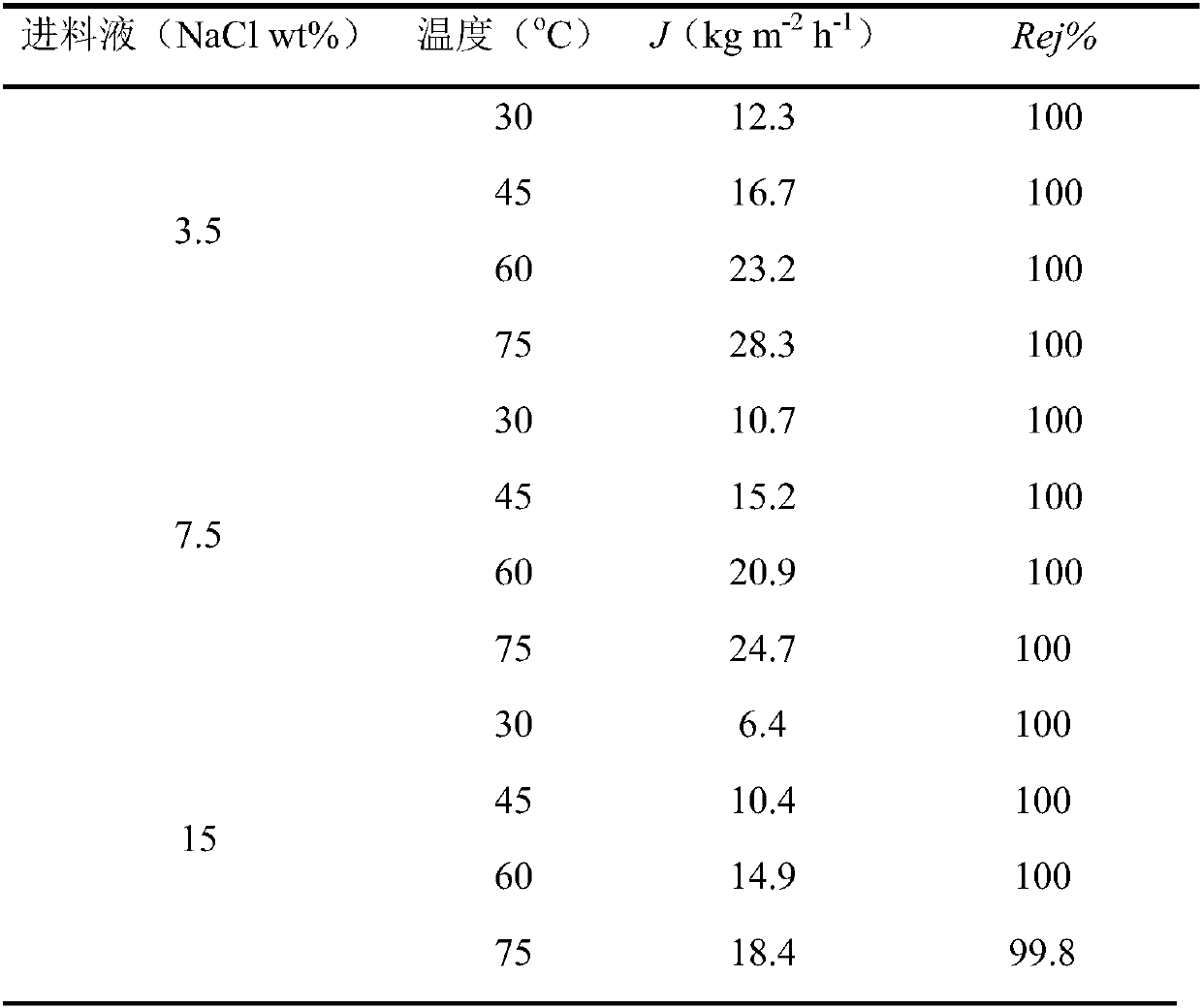

[0032] Change the boron-doped content (B / Si ratio, molar ratio) in silica sol, other preparation conditions are all identical with embodiment 1, can obtain the silica film of a series of different boron doping ratios (i.e. embodiment 2-4). The pervaporation desalination performance of these membranes was tested at a temperature of 60°C with an initial concentration of 3.5wt% NaCl solution as the feed solution, and the results are shown in Table 2.

[0033] Table 2. Pervaporation desalination performance of silica membranes in Examples 2-4 and Comparative Examples

[0034]

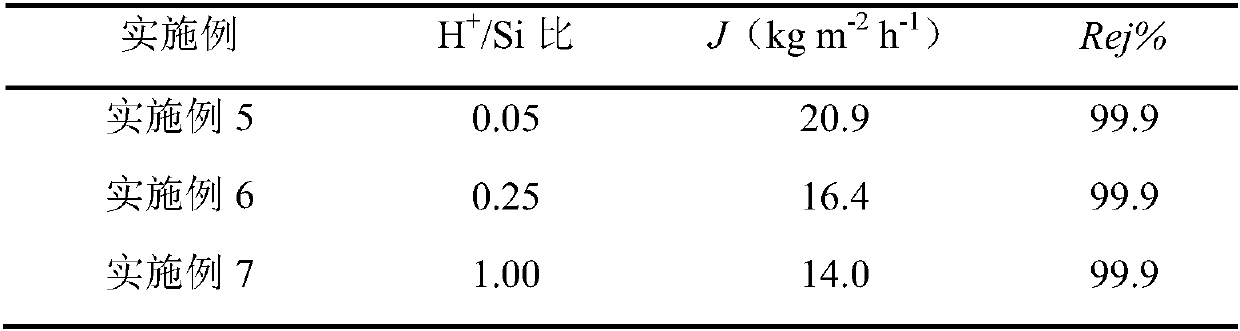

Embodiment 5-7

[0038] Changing the content of acid in the silica sol (H + / Si ratio, molar ratio), other preparation conditions are all the same as in Example 1, and a series of boron-doped silicon dioxide films (ie, Examples 5-7) under the action of catalysts with different acid amounts can be obtained. The pervaporation desalination performance of these membranes was tested at a temperature of 60°C with an initial concentration of 3.5wt% NaCl solution as the feed solution, and the results are shown in Table 3.

[0039] Table 3. Pervaporation desalination performance of boron-doped silica membranes in Examples 5-7

[0040]

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| salt rejection rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com