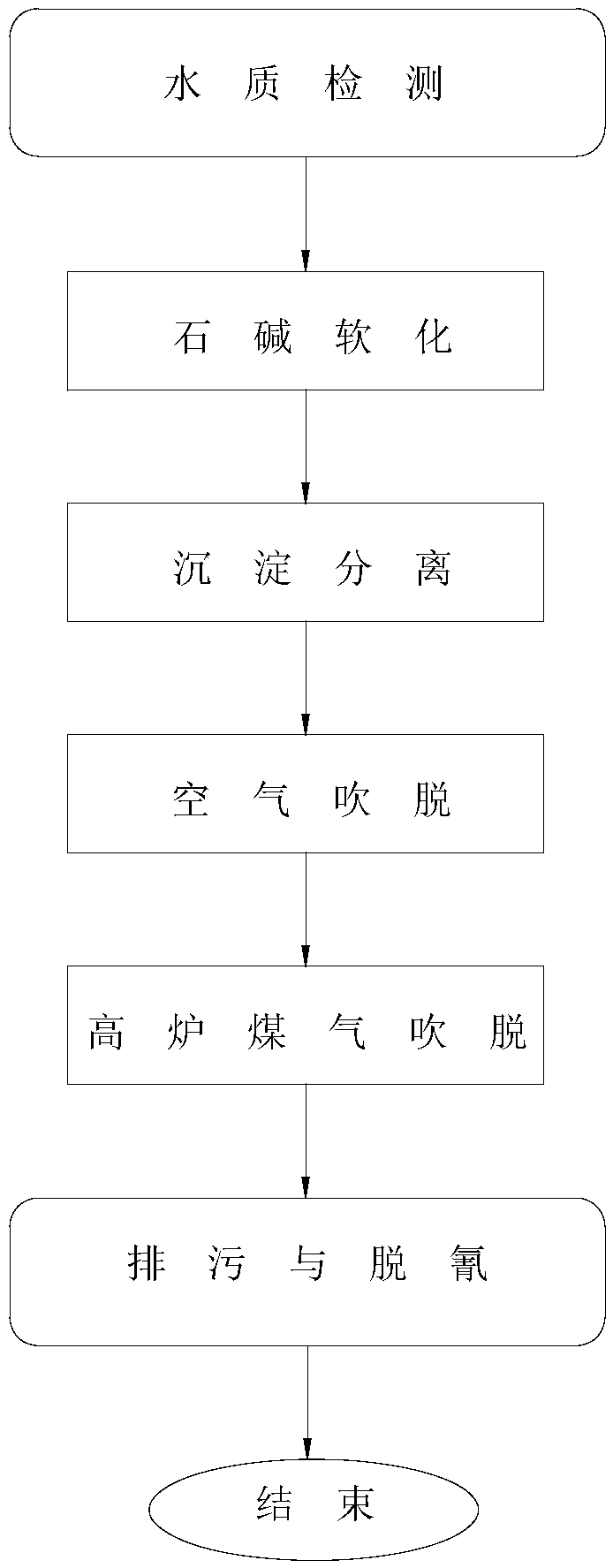

Ammonia nitrogen wastewater treatment method and ammonia nitrogen wastewater treatment system for wet dust collection blast furnace gas system

A technology for blast furnace gas and ammonia nitrogen wastewater, applied in gaseous effluent wastewater treatment, degassed water/sewage treatment, water treatment parameter control, etc., can solve the problems of reducing the discharge concentration and total amount of inorganic ammonia nitrogen wastewater, new energy consumption, etc. , to achieve the effect of reducing the amount of waste water, reducing the cost of chemicals, and saving engineering investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

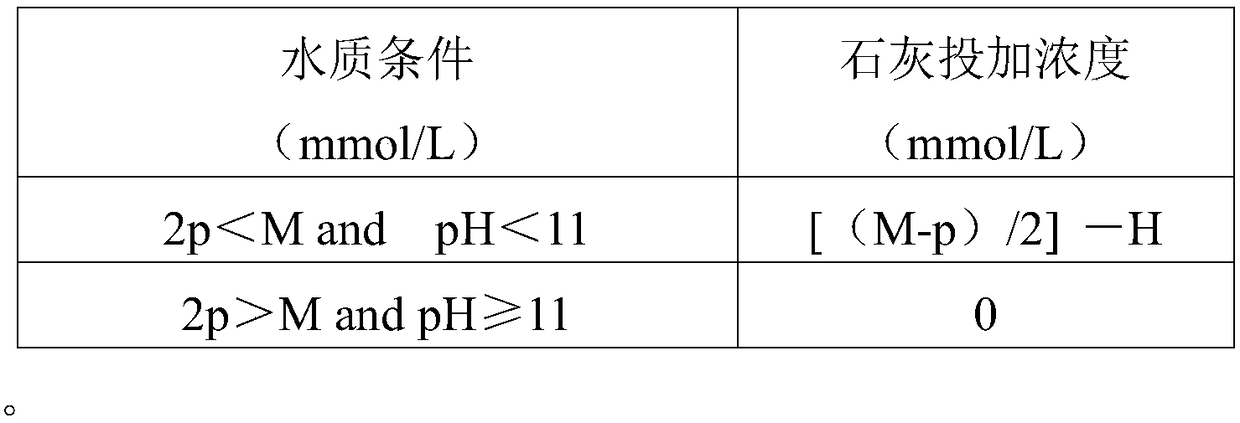

Method used

Image

Examples

Embodiment Construction

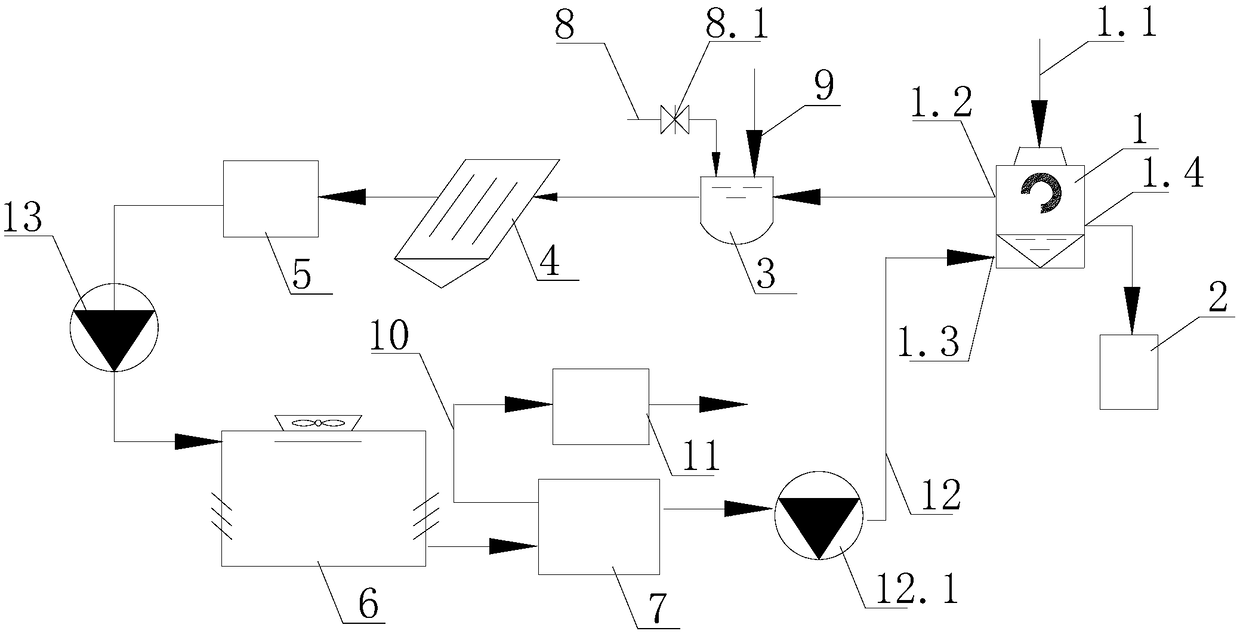

[0045] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments, so that those skilled in the art can understand.

[0046] Such as figure 2 The shown ammonia nitrogen wastewater treatment device comprises an annular seam annular seam washing tower 1, the top of the annular seam annular seam washing tower 1 is provided with a blast furnace gas inlet pipe 1.1, and the side wall of the annular seam washing tower 1 is from top to A washing return port 1.2 and a washing water inlet 1.3 are arranged at the bottom; a gas outlet 1.4 is also provided on the side wall of the annular seam washing tower 1, and the gas outlet 1.4 is connected to a gas utilization system 2, and the washing return port 1.2 passes through a pipeline The backwater elevated launder 3, sedimentation tank 4, hot water pool 5, upper tower pump 13, cooling tower 6 and cold water pool 7 are connected in sequence, and the return water elev...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com