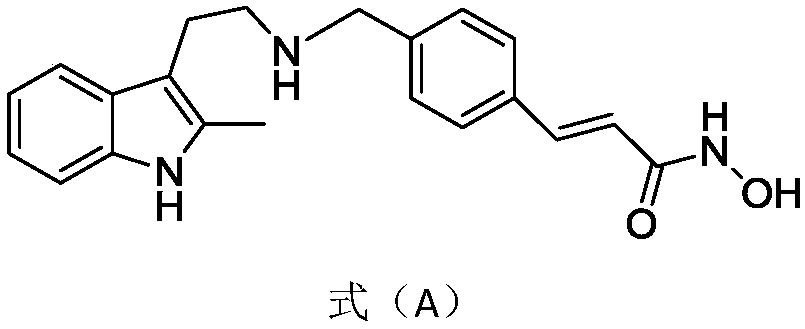

Panobinostat intermediate as well as synthesis and application thereof

A panobinostat and intermediate technology, which is applied in the field of drug synthesis, can solve the problems of unfavorable panobinostat raw material quality control, severe reaction conditions and high reaction temperature, and achieves easy quality control, simple operation and high yield. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

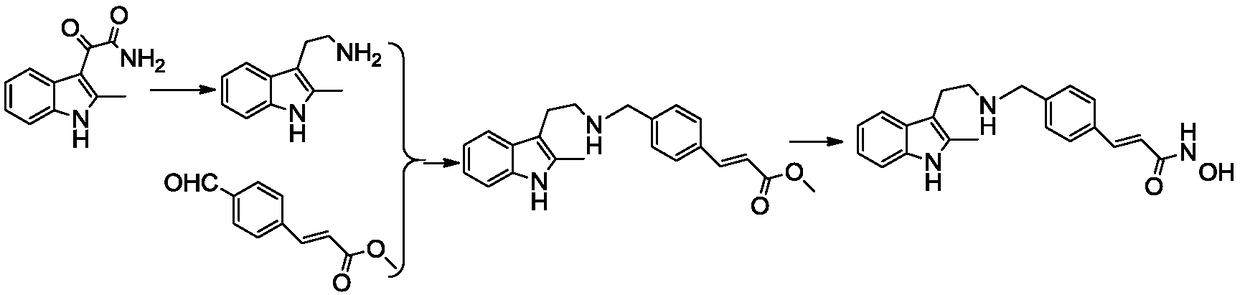

Method used

Image

Examples

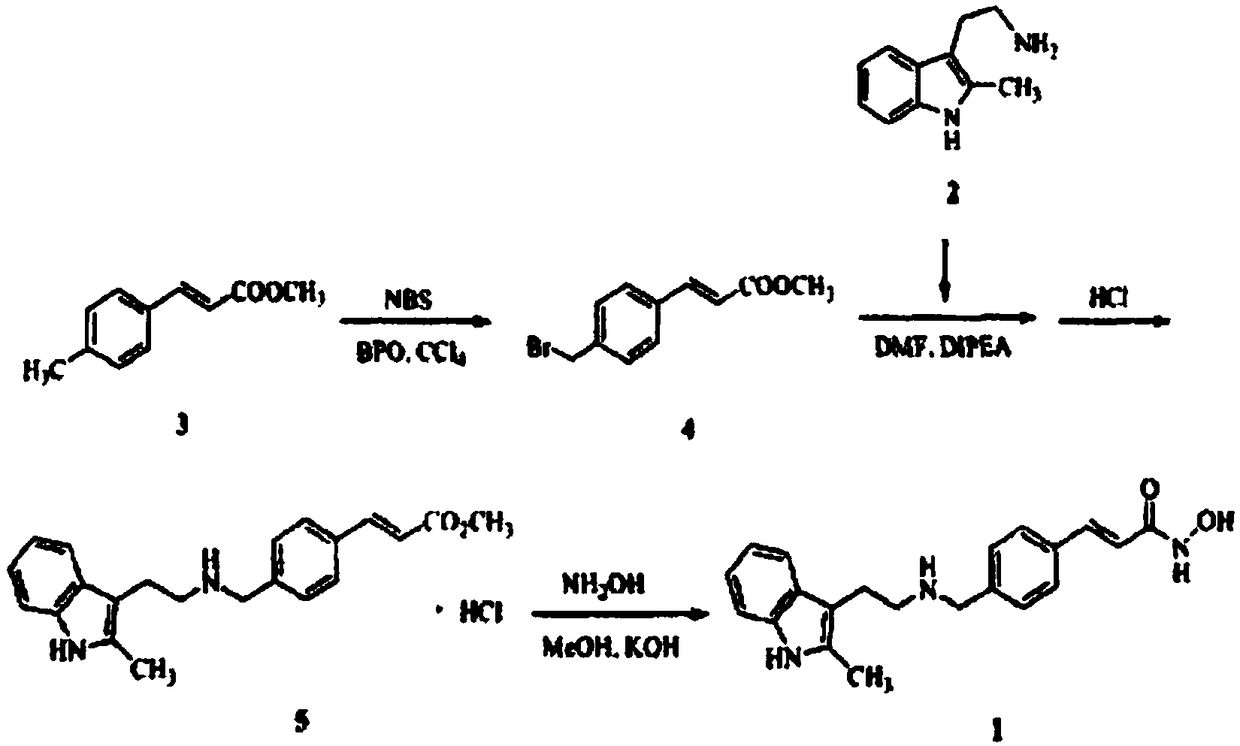

Embodiment 1

[0043] The preparation of embodiment 1 2-methyltryptamine

[0044]

[0045] Add phenylhydrazine (19.8ml, 200mmol) and absolute ethanol (120ml) into a 500ml three-neck flask, heat to 35°C, and N 2For protection, add 5-chloro-2-pentanone (25ml, 210mmol) ethanol solution (25ml) dropwise, heat up to 40°C and react for 30min, add ethanol 160ml and slowly heat up to reflux for 4h, spin to dry the solvent after suction filtration, add water ( 50ml), adjust the pH to acidic with 2M hydrochloric acid solution, extract with ethyl acetate (50ml*2), discard the organic phase, adjust the pH of the aqueous phase to alkaline with 20% NaOH solution, extract with ethyl acetate (50ml*2), The organic phases were combined, washed with water (50ml*2) and saturated chloride solution (50ml*2), dried over anhydrous sodium sulfate, filtered with suction, and spin-dried to obtain 24.2g of a red oily substance, with a yield of 70.1%.

Embodiment 24

[0046] Example 2 Preparation of 4-[[[2-(2-methyl-1H-indol-3-yl)ethyl]amino]methyl]benzaldehyde

[0047]

[0048] 2-Methyltryptamine (0.26g, 1.5mmol), DMF (5ml), and potassium carbonate (0.41g, 3mmol) were successively added to a 10ml single-necked bottle, N 2 Under protection, a DMF solution (2 ml) of 4-bromomethylbenzaldehyde (0.1 g, 0.5 mmol) was added dropwise. React at 0°C for 3 hours, pour the reaction solution into water (10ml), extract with ethyl acetate (10ml*3), combine the organic phases, and wash with water (10ml*3) and saturated sodium chloride solution (10ml*3) successively, without After drying with sodium sulfate, the filtrate was evaporated to dryness under reduced pressure to obtain 0.29 g of a light yellow solid with a yield of 68.0%.

[0049] 1 H NMR (600MHz, DMSO-d 6 )(δ,ppm):2.30(s,3H),2.72(m,2H),2.82(m,2H),3.76(s,3H),6.82-6.95(m,2H),7.20(d,1H) , 7.32 (d, 1H), 7.56 (d, 2H), 7.82 (d, 2H), 9.96 (brs, 1H), 10.68 (s, 1H).

[0050] ESI–MS: m / z 293.0[M+H...

Embodiment 34

[0051] Example 3 Preparation of 4-[[[2-(2-methyl-1H-indol-3-yl)ethyl]amino]methyl]benzaldehyde

[0052]

[0053] 2-Methyltryptamine (0.17g, 1.0mmol), DMF (5ml), and potassium carbonate (0.41g, 3mmol) were successively added to a 10ml single-necked bottle, N 2 Under protection, a DMF solution (2 ml) of 4-chloromethylbenzaldehyde (0.08 g, 0.5 mmol) was added dropwise. React at 10°C for 3 hours, pour the reaction solution into water (10ml), extract with ethyl acetate (10ml*3), combine the organic phases, and wash with water (10ml*3) and saturated sodium chloride solution (10ml*3) successively, without After drying with sodium sulfate, the filtrate was evaporated to dryness under reduced pressure to obtain 0.26 g of a light yellow solid with a yield of 60%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com