An anti-ultraviolet, flame-retardant and cut-resistant protective film

A cutting-resistant and protective film technology, which is applied in the field of wicker protective film processing, can solve the problems of willow products, such as adverse effects on the quality, loss of adhesion, and human and environmental hazards, to increase anti-ultraviolet and flame-retardant properties, and enhance cut resistance. Improvement of flexibility and self-adhesiveness, and flame retardancy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

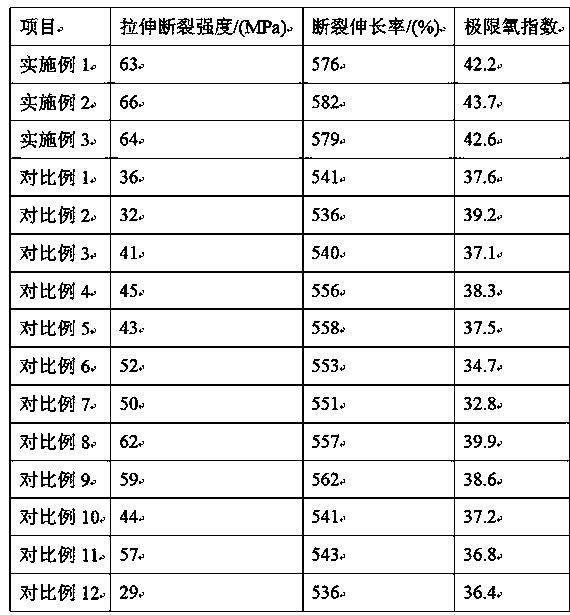

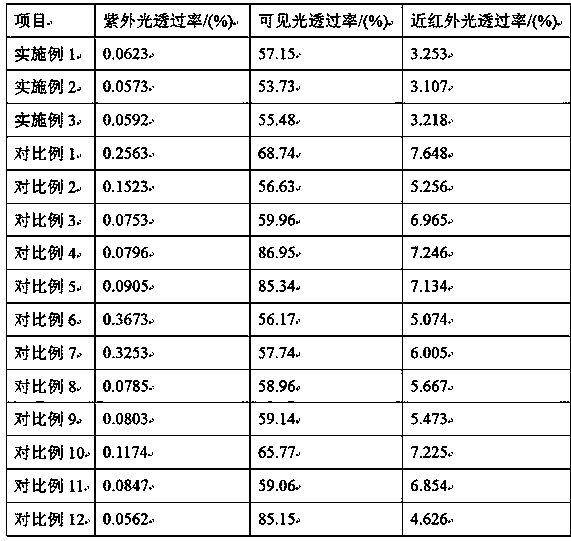

Examples

Embodiment 1

[0023] An anti-ultraviolet, flame-retardant and cut-resistant protective film, made of the following raw materials in parts by weight: modified PET 64, linear low-density polyethylene 22, polystyrene 11, vermiculite fiber 15, graphene fiber 7, titanium dioxide 3.5 , Nano zinc oxide 1.6.

[0024] For the modified PET, heat the PET to 190°C at a rate of 1.2°C / min, keep it warm for 15 minutes, add sulfamic acid, continue heating to 210°C, stir at constant temperature for 120 minutes, and gradually drop to room temperature to obtain modified PET , to promote the polymerization of sulfamic acid and PET branches, and improve the flexibility and flame retardancy of PET.

[0025] The linear low density polyethylene has a density of 0.919g / cm 3 , the melt flow rate is 30Max, the MI is 1.0g / 10min, and the turbidity is 49%.

[0026] The titanium dioxide is R-type titanium dioxide.

[0027] The nano zinc oxide has a particle size of 30~50nm and a specific surface area of 85~90m 2 / g...

Embodiment 2

[0035] An anti-ultraviolet, flame-retardant and cut-resistant protective film, made of the following raw materials in parts by weight: modified PET 65, linear low-density polyethylene 23, polystyrene 12, vermiculite fiber 16, graphene fiber 8, titanium dioxide 3.6 , Nano zinc oxide 1.7.

[0036] For the modified PET, heat the PET to 195°C at a rate of 1.3°C / min, keep it warm for 18 minutes, add sulfamic acid, continue heating to 215°C, stir at constant temperature for 130 minutes, and gradually drop to room temperature to obtain modified PET , to promote the polymerization of sulfamic acid and PET branches, and improve the flexibility and flame retardancy of PET.

[0037] The linear low density polyethylene has a density of 0.919g / cm 3 , the melt flow rate is 30Max, the MI is 1.0g / 10min, and the turbidity is 49%.

[0038] The titanium dioxide is R-type titanium dioxide.

[0039] The nano zinc oxide has a particle size of 30~50nm and a specific surface area of 85~90m 2 / g...

Embodiment 3

[0047] An anti-ultraviolet, flame-retardant and cut-resistant protective film, made of the following raw materials in parts by weight: modified PET 66, linear low-density polyethylene 24, polystyrene 13, vermiculite fiber 17, graphene fiber 9, titanium dioxide 3.7 , Nano zinc oxide 1.8.

[0048] For the modified PET, heat the PET to 200°C at a rate of 1.4°C / min, keep it warm for 20 minutes, add sulfamic acid, continue heating to 220°C, stir at constant temperature for 150 minutes, and gradually drop to room temperature to obtain modified PET , to promote the polymerization of sulfamic acid and PET branches, and improve the flexibility and flame retardancy of PET.

[0049] The linear low density polyethylene has a density of 0.919g / cm 3 , the melt flow rate is 30Max, the MI is 1.0g / 10min, and the turbidity is 49%.

[0050] The titanium dioxide is R-type titanium dioxide.

[0051] The nano zinc oxide has a particle size of 30~50nm and a specific surface area of 85~90m 2 / g...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com