Preparation method of permanent purple pigment

A technology of permanent violet and pigments, applied in organic dyes, etc., can solve the problems of low quality of permanent violet pigments, difficult recovery of crystal conversion solvents, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

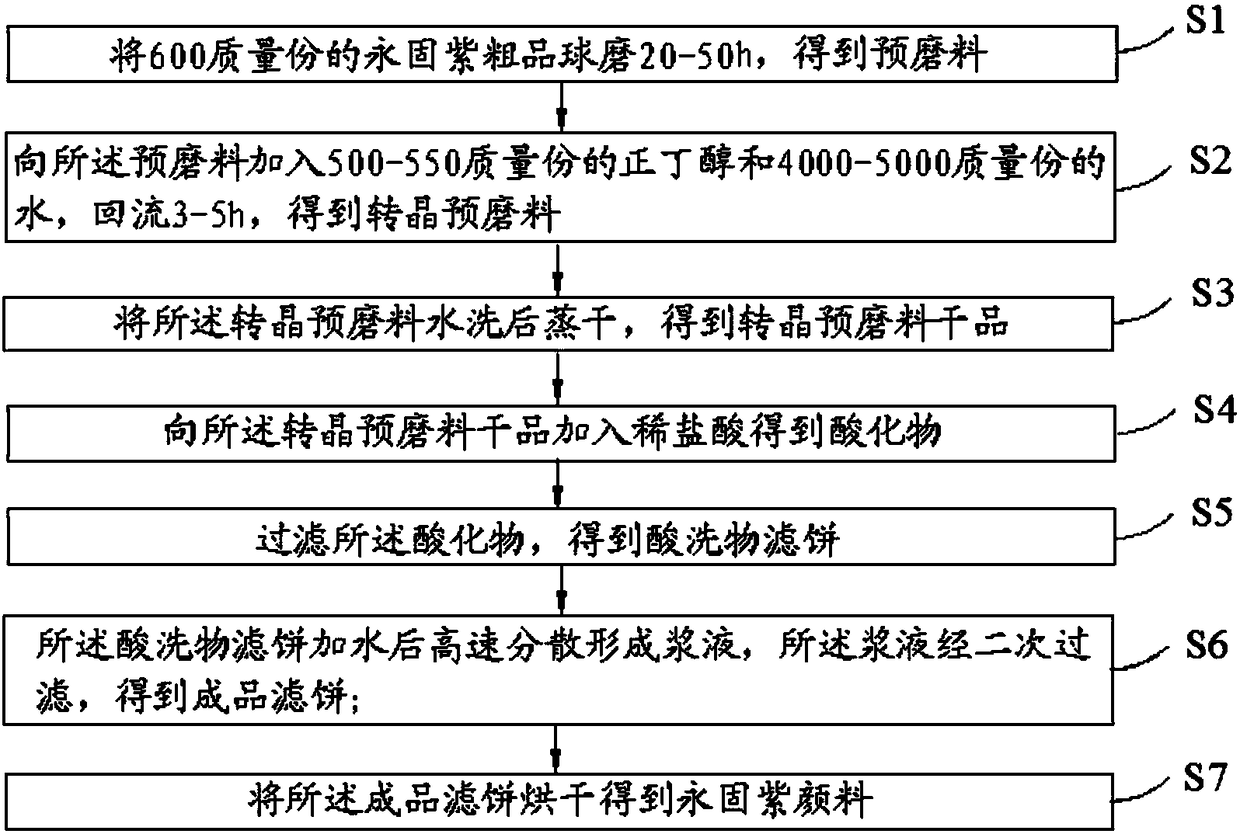

[0030] refer to figure 1 , the embodiment of the present application provides a preparation method of permanent violet pigment, comprising the following steps:

[0031] S1: ball mill 600 parts by mass of the crude permanent violet product for 20-50 hours to obtain pre-abrasive material;

[0032] The crude product of permanent violet is a dark green powder, which is a kind of α-type crystal. The α-type crystal has poor stability and large particles. Therefore, the coloring power of the crude product is low, so it is not suitable for use as a commercial pigment. It must be processed by pigmentation. Reduce its particle size and transform it into β-type crystals with stable performance, strong tinting strength and bright color.

[0033] The crude everlasting violet is put into a bedroom ball mill, and ball milled under the condition of cooling water to reduce the particle size of the crude everlasting violet.

[0034] Among them, the bedroom ball mill is a conventional ball mil...

Embodiment 1

[0053] S11: put 600 parts by mass of the crude permanent violet product into a bedroom ball mill, and perform ball milling under the condition of cooling water for 20 hours to obtain a pre-abrasive material;

[0054] S12: Add 550 parts by mass of n-butanol and 4000 parts by mass of water to the pre-abrasive material, and reflux for 5 hours to obtain a pre-abrasive material for crystal conversion;

[0055] S13: washing the crystal-transforming pre-abrasive with water and then evaporating to dryness to obtain a dry product of the crystal-transforming pre-abrasive;

[0056] S14: adding 8% dilute hydrochloric acid to the dry pre-abrasive material for crystal transformation to obtain an acidified product;

[0057] 8% dilute hydrochloric acid can react well with iron filings, so as to remove iron filings in dry pre-abrasive materials for crystal transformation. If the mass fraction of hydrochloric acid is too high, it will cause waste of hydrochloric acid resources; at the same tim...

Embodiment 2

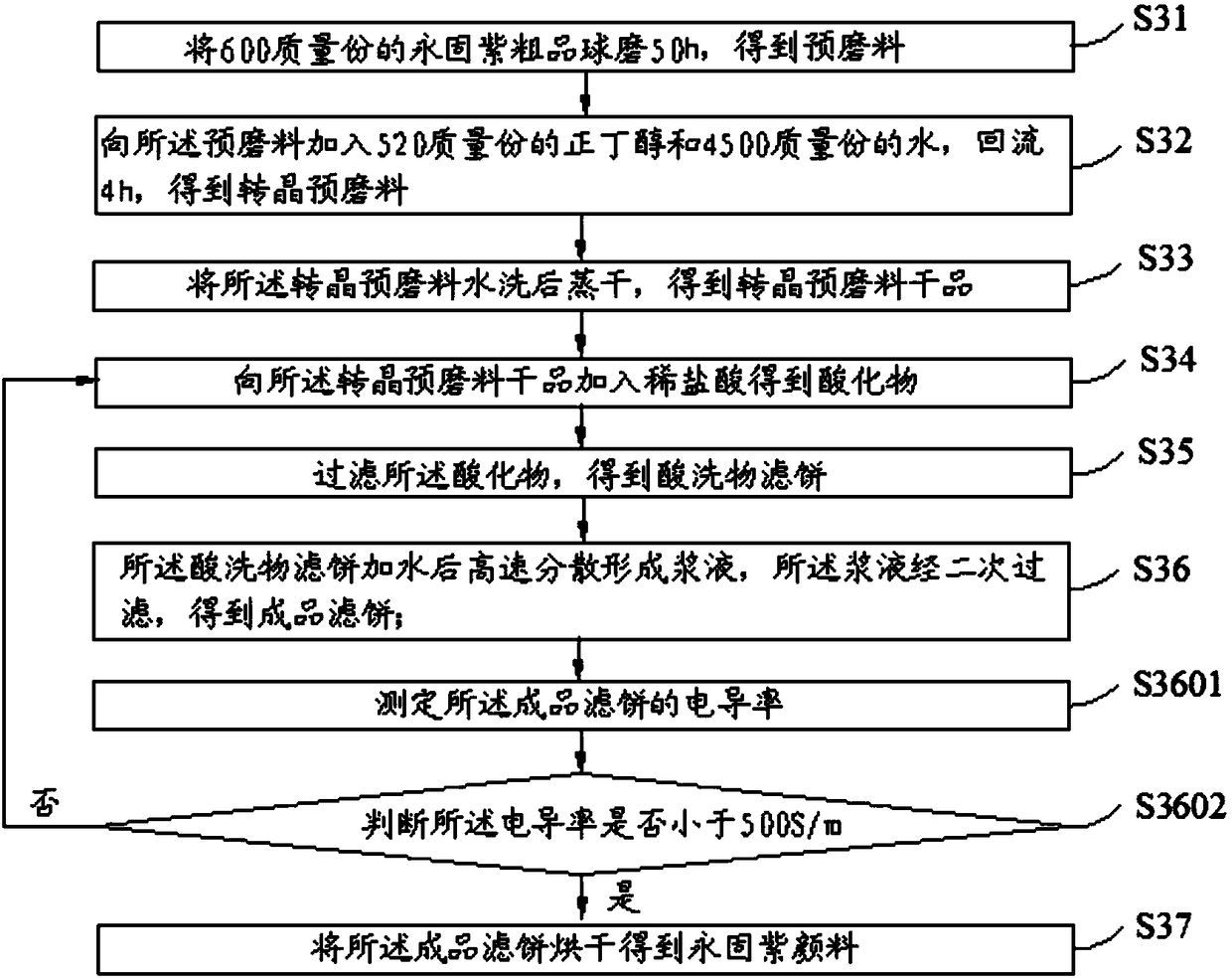

[0067] refer to figure 2 , figure 2 It is a flow chart of another permanent violet pigment preparation method provided in the examples of this application.

[0068] S21: ball milling 600 parts by mass of the crude permanent violet product for 30 hours to obtain a pre-abrasive material;

[0069] S22: Add 500 parts by mass of n-butanol and 5000 parts by mass of water to the pre-abrasive material, and reflux for 3 hours to obtain a pre-abrasive material for crystal conversion;

[0070] S23: washing the crystal-transforming pre-abrasive with water and then evaporating to dryness to obtain a dry product of the crystal-transforming pre-abrasive;

[0071] S24: adding 8% dilute hydrochloric acid to the dry pre-abrasive material for crystal transformation to obtain an acidified product;

[0072] S25: filtering the acidified product to obtain a filter cake of the acidified product;

[0073] S26: Adding water to the acid-washed product filter cake disperses at high speed to form a ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Conductivity | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com