Expansion refrigeration method for separating coke oven gas by using nitrogen and helium

A technology of expansion refrigeration and coke oven gas, which is applied in the direction of gas fuel, combustible gas purification, climate sustainability, etc., can solve the problems of complicated process and difficult to guarantee stability, so as to reduce environmental pollution, reduce emptying phenomenon, improve Effect of Utilization Efficiency and Energy Utilization Rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

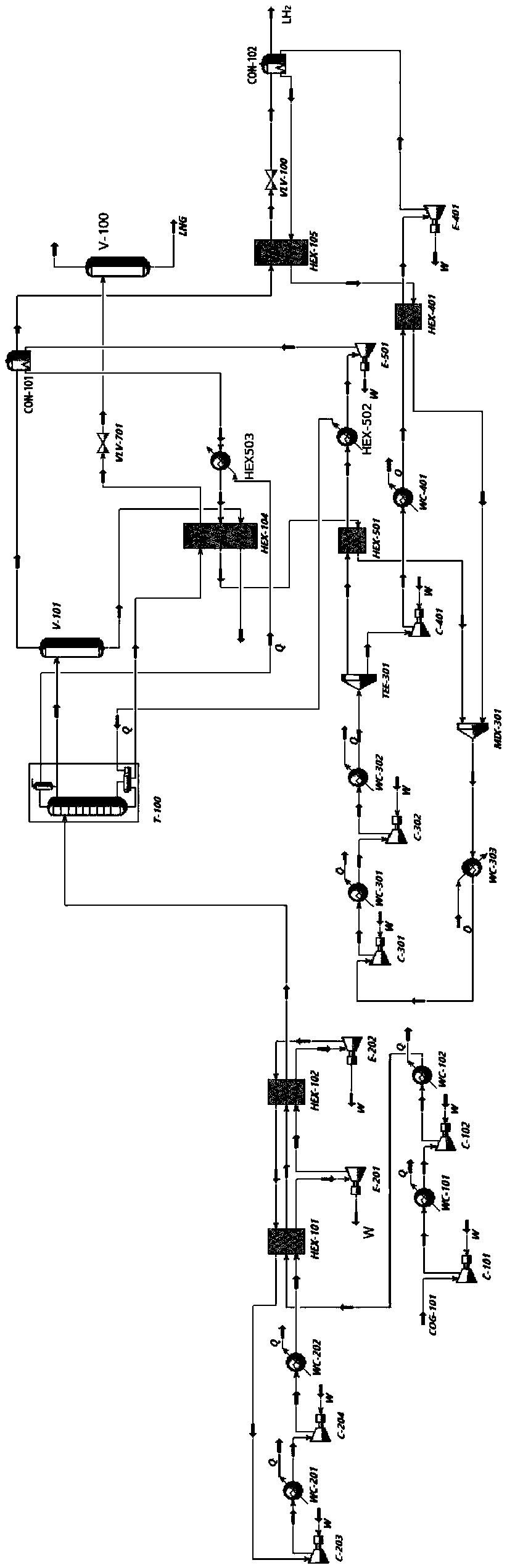

[0035] A low-temperature cycle for producing liquefied natural gas (LNG) and liquid hydrogen (LH) from coke oven gas by using nitrogen and helium expansion 2 ) process, the implementation scheme is as figure 1 shown. The gas expansion cycle refrigerants are pure nitrogen and helium, of which the low-temperature working medium of the first expansion cycle is nitrogen, and the low-temperature working medium of the other two expansion cycles is helium, and the three-stage expansion cycle refrigerant flow rate is 5000 kmol / h , 5000kmol / h, 5500kmol / h, the raw coke oven gas includes the following mole fraction components: 50% CH 4 +50%H 2 , the pressure of coke oven gas is 0.2MPa, the temperature is 35°C, and the flow rate is 1000kmol / h. The specific steps of using coke oven gas to produce liquefied natural gas and liquid hydrogen are as follows:

[0036] 1) Change CH 4 and H 2 The purified coke oven gas COG-101 with a mole fraction of 50% is introduced into two-stage compressi...

Embodiment 2

[0049] A low-temperature cycle for producing liquefied natural gas (LNG) and liquid hydrogen (LH) from coke oven gas by using nitrogen and helium expansion 2 ) process, the implementation scheme is as figure 1 shown. The gas expansion cycle refrigerants are pure nitrogen and helium, of which the low-temperature working medium of the first expansion cycle is nitrogen, and the low-temperature working medium of the other two expansion cycles is helium, and the three-stage expansion cycle refrigerant flow rate is 5000 kmol / h , 4800kmol / h, 4600kmol / h, the raw coke oven gas includes the following mole fraction components: 60% CH 4 +40%H 2 , the pressure of coke oven gas is 0.2MPa, the temperature is 35°C, and the flow rate is 1000kmol / h. The specific steps of using coke oven gas to produce liquefied natural gas and liquid hydrogen are as follows:

[0050] 1) Change CH 4 and H 2 The purified coke oven gas COG-101 with mole fractions of 60% and 40% respectively is introduced into...

Embodiment 3

[0063] A method utilizing nitrogen and helium expansion refrigeration to separate coke oven gas, the method comprising the following steps:

[0064] 1) After the coke oven gas is compressed and pre-cooled, it is sent to the first-stage nitrogen cycle expansion refrigeration system, and then sent to the rectification tower after further cooling;

[0065] 2) After the methane discharged from the bottom of the rectification tower is cooled and liquefied by the secondary helium circulation expansion refrigeration system, it is sent to the storage tank of liquefied natural gas for storage. After the transformation of normal and secondary states, it is sent to the liquid hydrogen storage tank for storage, wherein, the first normal and secondary state conversion process is provided by the second-stage helium cycle expansion refrigeration system, and the second normal and secondary state conversion process is provided by the third-stage helium cycle expansion refrigeration system. The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com