Mixed probiotics for soybean meal fermentation and fermentation method

A technology of probiotics and soybean meal, applied in the direction of microorganism-based methods, biochemical equipment and methods, bacteria used in food preparation, etc., can solve the problem of single function of fermented products and inability to make full use of soybean meal nutrients, strains, and unsatisfactory processes The same problems, to achieve the effect of improving digestion and absorption rate, improving the quality of livestock and poultry products, and improving comprehensive utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

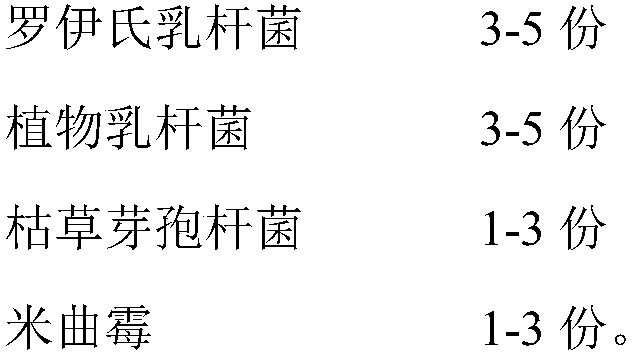

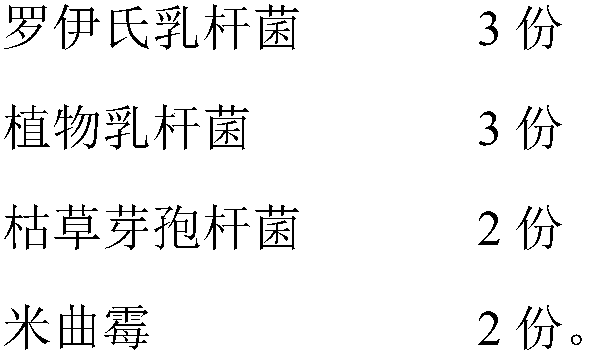

Embodiment 1

[0024] In this example, Lactobacillus reuteri, Lactobacillus plantarum, Bacillus subtilis and Aspergillus oryzae were mixed according to the weight ratio of 3:3:2:2 to obtain mixed probiotics, which were inserted into the solid-state fermentation medium according to the inoculum size of 8%. , the material-to-water ratio is 1.5:1 (material: water), and the fermentation time is 48 hours. After the fermentation is completed, the fermented solid-state fermentation medium is dried and pulverized through a 40-mesh sieve to obtain a fermented product.

[0025] Wherein, the weight percent of each component in the solid-state fermentation medium is: 15%-30% of soybean meal, 20%-60% of corn, 5%-15% of rice bran meal, 5%-20% of skimmed milk powder, and 2% of whey powder -15%, Glucose 1%-10%.

Embodiment 2

[0027] This example is a verification example.

[0028] In this example, Escherichia coli K88 was used as the experimental object to verify the antibacterial ability of the mixed probiotic fermentation product of the present invention.

[0029] Take by weighing 1g of the fermented product prepared by the fermentation method of the present invention in a sterilized test tube, add sterile water in a ratio of 1:2 (m / v), mix well, centrifuge at 3000r / min for 10min, and take the supernatant to Escherichia coli K88 was used for antibacterial experiment. In the antibacterial experiment, add 100 μL of pathogenic bacteria to each plate to coat the plate, use an Oxford cup to add samples, add 200 μL of samples to each well, and do 2 parallels for each pathogenic bacteria. Incubate in a 37°C incubator for 8 hours.

[0030] Take it out and observe, the result is as attached figure 1 shown. Among them, the upper two parallel groups of inhibition zones are the experimental group, and th...

Embodiment 3

[0033] This example is a verification example.

[0034] This example verifies the change of nutritional components of soybean meal before and after fermentation of soybean meal with mixed probiotics of the present invention.

[0035] Experimental results show that under the same dry matter basis, the crude protein in soybean meal fermented by the mixed probiotics of the present invention is 5.21% higher than that of unfermented soybean meal, and the number of beneficial bacteria reaches 5.81×108cfu / g, and the lactic acid content reaches 6.14%; antigenic protein and undesirable oligosaccharides were analyzed by SDS-PAGE electrophoresis and TLC plate analysis respectively. Compared with before fermentation, antigenic protein and undesirable oligosaccharides were almost completely degraded after fermentation.

[0036] The above results show that the mixed probiotics of the present invention can not only degrade the anti-nutritional factors in soybean meal, but also fully decompos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com