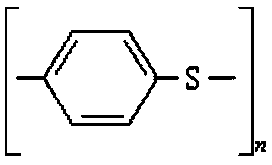

Melt-blowing polyphenylene sulfide non-woven fabric filter material for lowering e-liquid content and preparation method of material

A technology of polyphenylene sulfide and filter materials, which is applied in the field of textile materials and non-woven fabrics, can solve the problems of undiscovered tar uses and complicated methods, and achieve excellent tar adsorption effects, uniform thickness distribution, and small fiber diameters

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

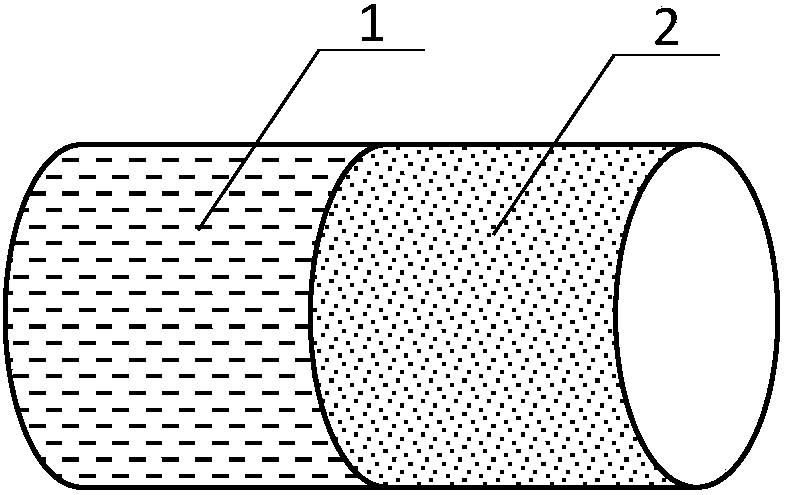

[0033] A kind of preparation method of the melt-blown polyphenylene sulfide non-woven filter material that is used to reduce tar amount, described preparation method is carried out according to the following steps:

[0034] a. Drying of polyphenylene sulfide resin

[0035] Drying a certain amount of polyphenylene sulfide resin at a temperature of 100° C. for 24 hours to make the water content less than 0.2%.

[0036] b. Preparation of polyphenylene sulfide

[0037] The dried polyphenylene sulfide resin is fed into the screw area through the hopper, and the uniformly plasticized polyphenylene sulfide melt is obtained by screw extrusion and shearing, and then the melt is filtered and metered to reach the spinneret. When the melt When extruded from the spinneret, it will be drawn into polyphenylene sulfide fibers by hot air. Among them, the basic parameters of the melt-blown equipment are: the length-to-diameter ratio of the screw extruder is 40:1, the feeding zone is 190°C, th...

Embodiment 2

[0043] A kind of preparation method of the melt-blown polyphenylene sulfide non-woven filter material that is used to reduce tar amount, described preparation method is carried out according to the following steps:

[0044] a. Drying of polyphenylene sulfide resin

[0045] Drying a certain amount of polyphenylene sulfide resin at a temperature of 100° C. for 24 hours to make the water content less than 0.2%.

[0046] b. Preparation of polyphenylene sulfide

[0047] The dried polyphenylene sulfide resin is fed into the screw area through the hopper, and the uniformly plasticized polyphenylene sulfide melt is obtained by screw extrusion and shearing, and then the melt is filtered and metered to reach the spinneret. When the melt When extruded from the spinneret, it will be drawn into polyphenylene sulfide fibers by hot air. Among them, the basic parameters of the melt-blown equipment are: the length-to-diameter ratio of the screw extruder is 40:1, the feeding zone is 190°C, the ...

Embodiment 3

[0054] A melt-blown polyphenylene sulfide non-woven fabric filter material for reducing the amount of tar is prepared by using the non-woven fabric of Example 1, and the fiber diameter of the melt-blown polyphenylene sulfide non-woven fabric is 10-20 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap