An Intelligent Control Method for Rodless Oil Well Lifting System

An intelligent control and oil well technology, applied in pump control, earthwork drilling, wellbore/well components, etc., can solve the problems of rodless pump application range limitation, difficulty in reducing speed, damage to rubber stator, etc., to avoid dry grinding and rapid Effects of damage, low energy consumption cost, and reduced running resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] The present invention will be further elaborated below in conjunction with the accompanying drawings of the description.

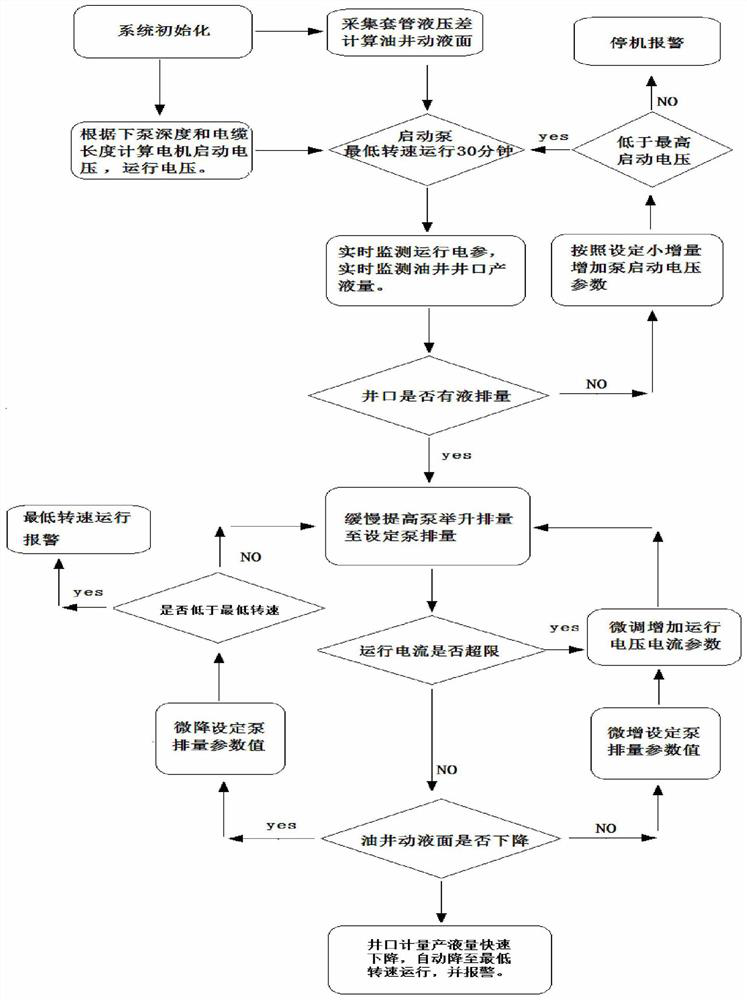

[0049] Such as figure 1 As shown, an intelligent control method of a rodless oil well lifting system of the present invention comprises the following steps:

[0050] After the system is initialized, the hydraulic pressure difference of the rodless lifting system is collected to calculate the oil well liquid level;

[0051] After starting the submersible screw pump to run for a specified time, real-time monitoring of operating electrical parameters and wellhead liquid production of oil wells;

[0052] When there is liquid displacement at the wellhead, increase the pump lift displacement to the set pump lift displacement;

[0053] When the operating current of the submersible screw pump does not exceed the limit, it is judged whether the dynamic liquid level of the oil well has dropped;

[0054] If the dynamic liquid level of the oil well drops due...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com