Novel ash removing device and method for low-low-temperature coal economizer

A technology of low and low temperature economizer and ash cleaning device, which is applied in the direction of cleaning heat transfer device, combustion method, feed water heater, etc. Boiler economy and safety, the ability of flue gas to carry fly ash is weakened, etc., to achieve the effect of reducing flue ash accumulation, improving ash carrying capacity, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

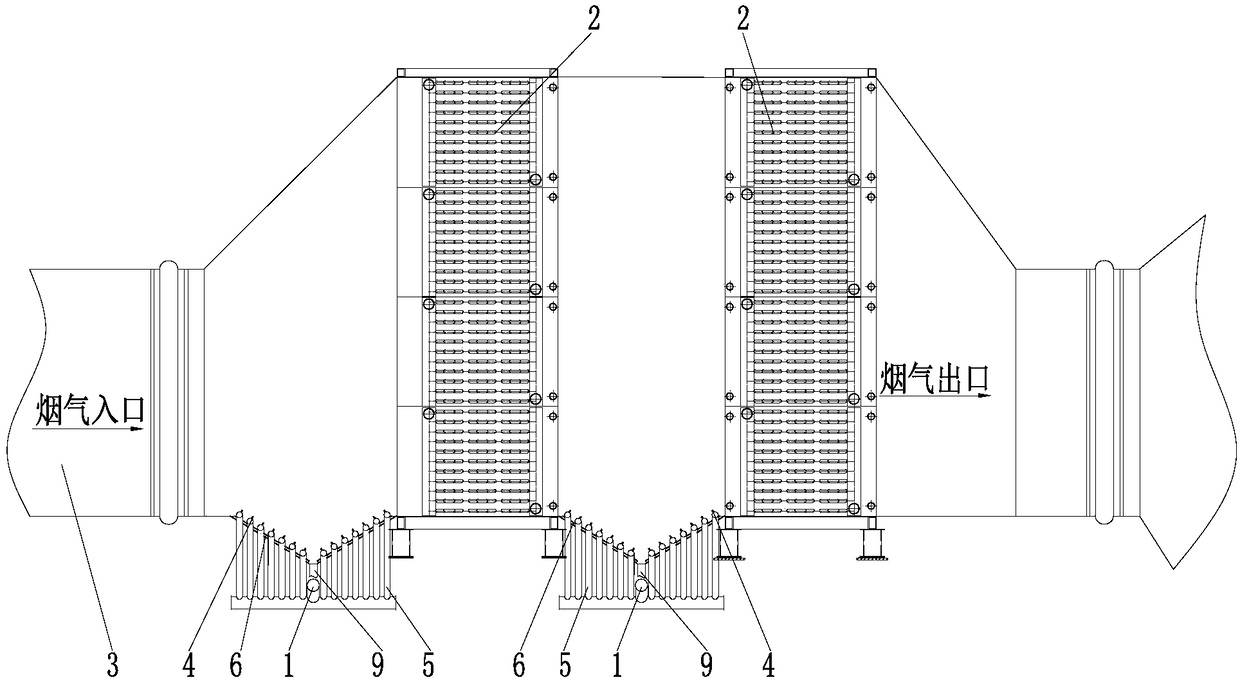

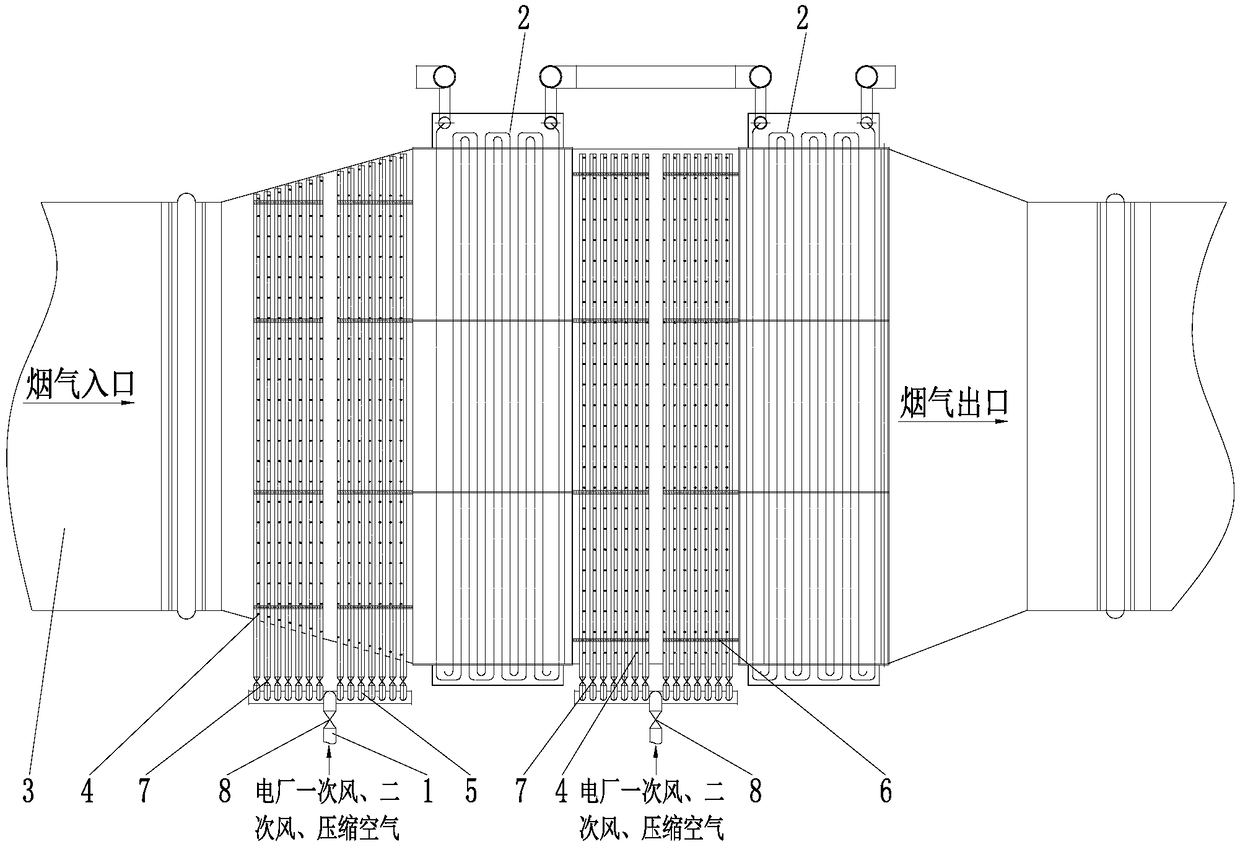

[0028] Embodiment 2: as Figure 1-Figure 3As shown, the soot cleaning device of the new low-low temperature economizer, wherein a heat exchanger group is arranged in the flue of the low-low temperature economizer, and the heat exchanger group includes m vertically arranged (that is, the flue section is from top to bottom Direction setting) set heat exchange modules 2, n heat exchange modules 2 arranged horizontally (ie set flue gas flow direction), m and n are both natural numbers greater than 1, specifically, m is 4, n is 2. A set of ash removal devices is installed in the third-stage flue at the entrance of the low-temperature economizer before the dust collector, and another set of ash removal devices is installed between the heat exchanger groups. The ash removal devices all include the ash removal main pipe 1, Soot cleaning nozzle 4, soot cleaning branch pipe 5, branch pipe valve 7 and main pipe valve 8, one end of the several ash cleaning branch pipes 5 is connected with...

Embodiment 3

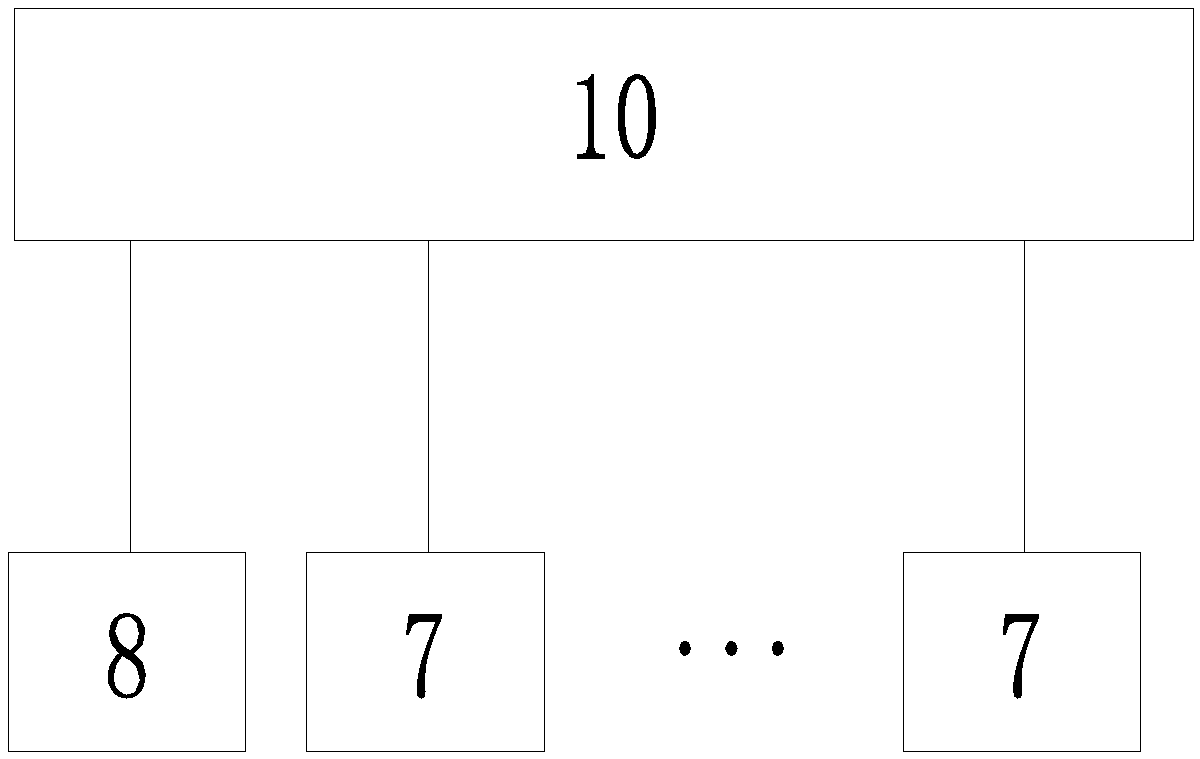

[0030] Embodiment 3: as Figure 1-Figure 2 As shown, the ash removal method of the new low-low temperature economizer adopts the aforesaid ash removal device of the new low-low temperature economizer, including the following method: the control system 10 adjusts the opening quantity and opening frequency of the branch valve 7 according to the load signal of the boiler , also adjust the opening frequency of the main pipe valve 8, so that when the boiler load is low and the ash-carrying capacity of the flue gas is weak, in order to prevent ash accumulation, the branch pipe valve 7 and the main pipe valve 8 need to be opened, so that the ash cleaning main pipe 1 The purge medium enters the flue through the soot removal branch pipe 5 and the soot removal nozzle 4 to sweep upwards, and the flue gas is suspended by the air volume and wind pressure, so that the dust will not fall to the bottom plate of the flue, reducing the dust load of the flue, The deposited fly ash is carried awa...

Embodiment 4

[0031] Embodiment 4: as Figure 1-Figure 2 As shown, the soot cleaning device of the new low-low temperature economizer, wherein a heat exchanger group is arranged in the flue of the low-low temperature economizer, and the heat exchanger group includes m vertically arranged (that is, the flue section is from top to bottom Direction setting) heat exchange modules 2, n heat exchange modules 2 arranged in a horizontal arrangement (that is, flue gas flow direction setting), m and n are both natural numbers greater than 1. A set of ash removal devices is installed in the third-stage flue at the entrance of the low-temperature economizer before the dust collector, and another set of ash removal devices is installed between the heat exchanger groups. The ash removal devices all include the ash removal main pipe 1, Soot cleaning nozzle 4, soot cleaning branch pipe 5, branch pipe valve 7 and main pipe valve 8, one end of the several ash cleaning branch pipes 5 is connected with a soot ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com