Composite carbon material as well as preparation method and application thereof

A technology of composite carbon and carbon layer, applied in nanotechnology for materials and surface science, fuel cell-type half-cell and secondary battery-type half-cell, electrical components, etc., can solve the problem of poor oxygen reduction catalytic performance And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

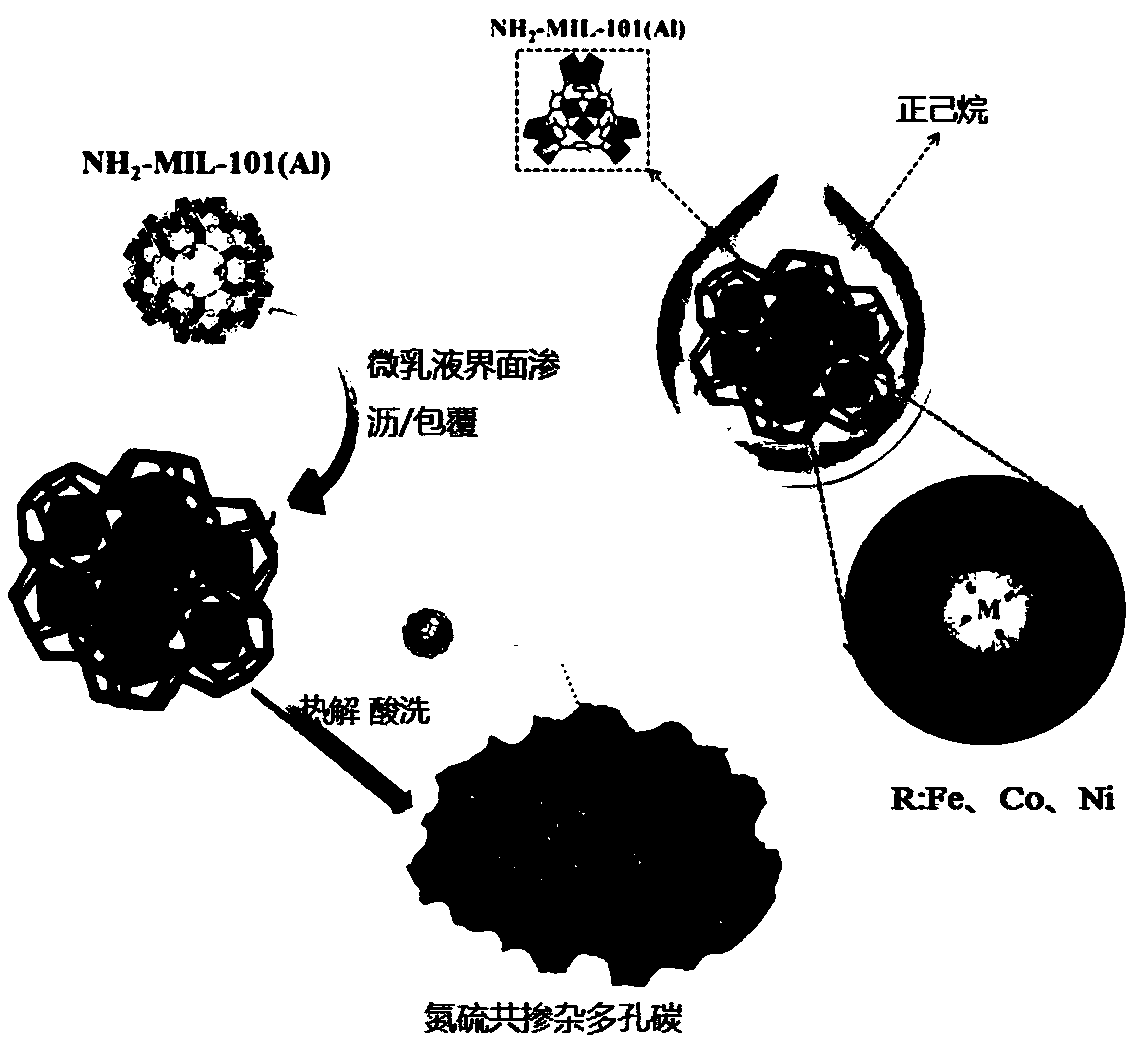

[0037] The invention provides a kind of preparation method of composite carbon material, comprises the following steps:

[0038] (1) Mix transition metal coordination compound, thiourea, ethanol and water to obtain transition metal coordination compound precursor solution, and the transition metal coordination compound is ferric chloride hexahydrate, cobalt chloride hexahydrate or hexahydrate nickel chloride;

[0039] (2) adding the transition metal coordination compound precursor solution obtained in the step (1) dropwise into a hydrophobic organic solvent to obtain a transition metal coordination compound precursor microemulsion;

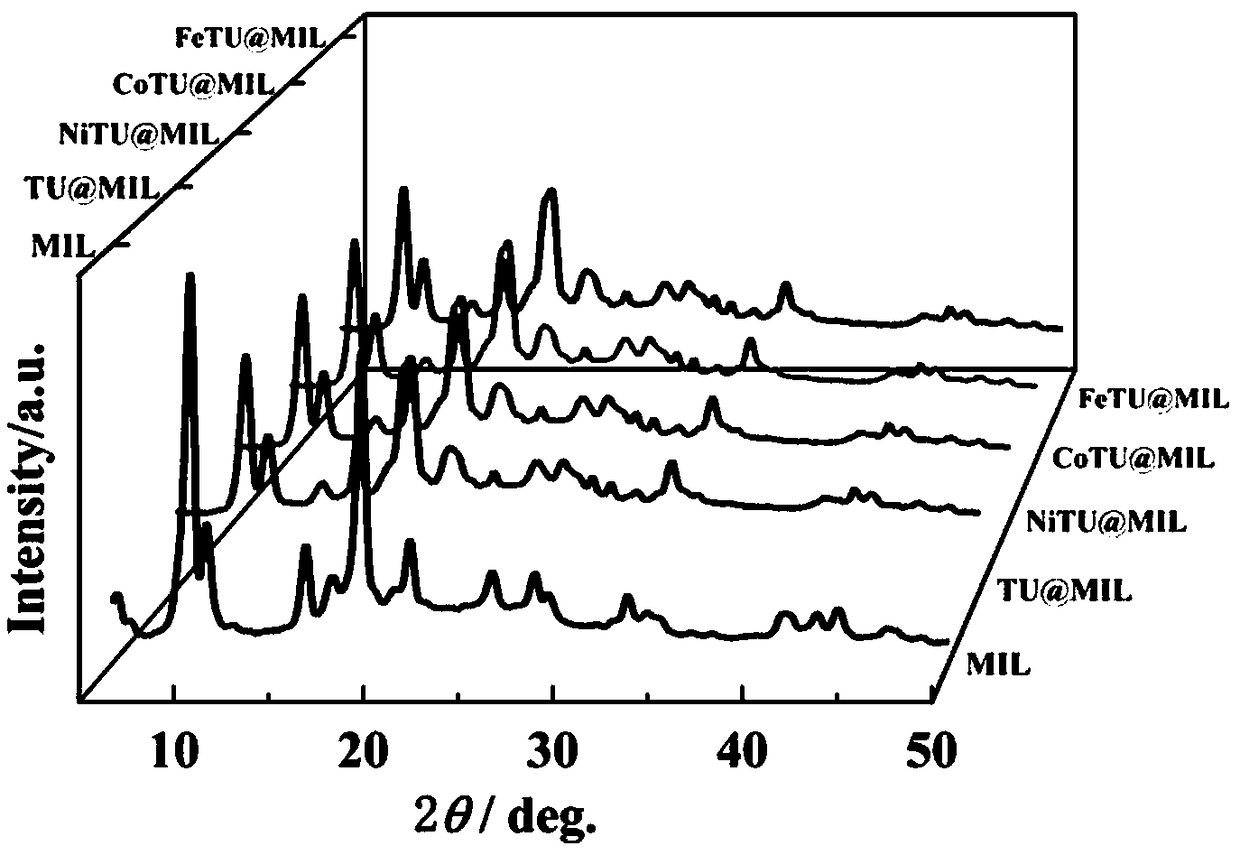

[0040] (3) NH 2 -MIL-101 (A1) is added to the transition metal coordination compound precursor microemulsion obtained in the step (2) to obtain RTU@NH 2 -MIL-101(A1), R is Fe(III), Co(II) or Ni(II);

[0041] (4) RTU@NH obtained in the step (3) 2 -MIL-101 (A1) is carbonized to obtain a carbonized product;

[0042] (5) After the carbonized prod...

Embodiment 1

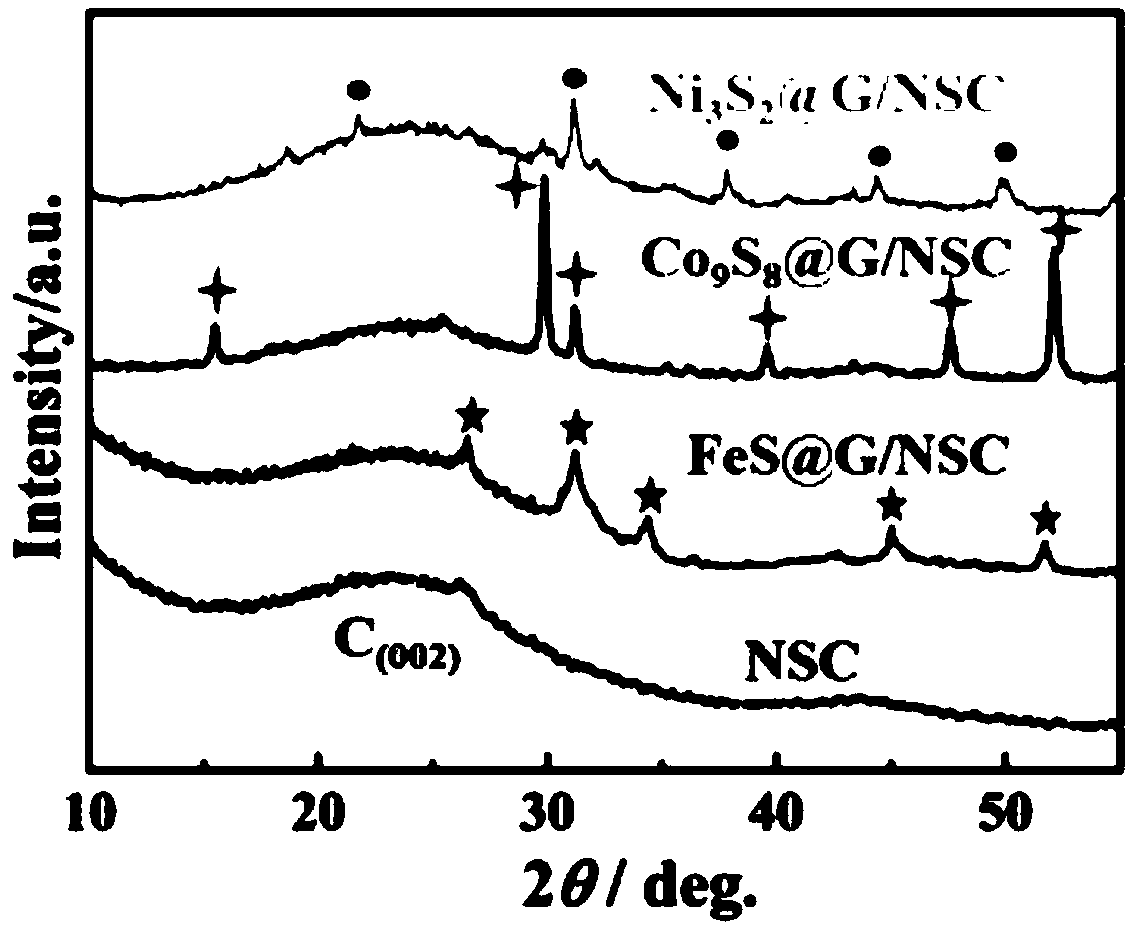

[0070] A mixed water-ethanol solution (1 mL, 1:1) containing thiourea (TU, 60 mg) and ferric chloride hexahydrate (60 mg) was slowly added dropwise into n-hexane (60 mL) and vigorously stirred for 1 hour to form a transition Metal complex precursor microemulsion. Then NH 2 - MIL-101(A1) (1 g) was added into the microemulsion and continued to stir for 6 hours. After the stirring was completed, the precipitate was separated by filtration and dried overnight at 60 °C to obtain FeTU@NH 2 -MIL-101(A1), then FeTU@NH 2 -MIL-101(A1) high-purity N in a temperature-programmed furnace 2 Under the atmosphere, carbonize at 900°C for 5 hours, the heating rate is 5°C / min, and then cool to room temperature to obtain a black product, leaching with black product HF (10%), and then washing with a large amount of water. The obtained sample was dried under vacuum and labeled as FeS@G / NSC.

Embodiment 2

[0074] The same as the method of Example 1, the only difference is that ferric chloride hexahydrate is replaced by cobalt dichloride hexahydrate, and the final product obtained is marked as Co 9 S 8 @G / NSC.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com