Nanocomposite gel electrolyte, lithium secondary battery and preparation method of lithium secondary battery

A gel electrolyte and lithium secondary battery technology, applied in the direction of non-aqueous electrolyte batteries, secondary batteries, lithium batteries, etc., can solve the problems of large interface resistance, unfavorable solid electrolyte performance, poor contact, etc., and achieve low interface impedance, The effect of good compatibility and cycle stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

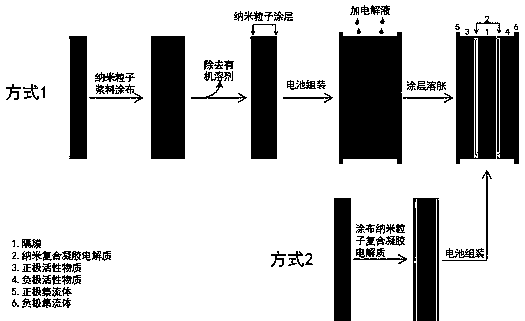

Image

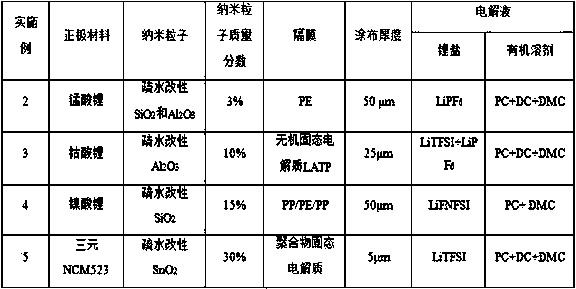

Examples

Embodiment 1

[0032] A lithium secondary battery, the structure of which comprises:

[0033] (1) A positive pole piece, which includes a positive current collector 5 and a positive active material 3;

[0034] (2) a negative electrode sheet, which includes a negative electrode current collector 6 and a negative electrode active material 4;

[0035] (3) Diaphragm 1;

[0036] (4) Nanocomposite gel electrolyte 2, which is used to space between the separator 1 and the positive and negative pole pieces.

[0037] The preparation method of lithium secondary battery is as follows:

[0038] (1) Hydrophobic Al 2 o 3 Preparation of nanoparticles: the Al 2 o 3 Nanoparticles and silane coupling agent were ultrasonically dispersed in ethanol, stirred at 70°C for 6 h, separated by centrifugation or filtration, washed with ethanol, and finally dried in vacuum.

[0039] (2) Coating the positive electrode material nickel-cobalt-manganese ternary material NCM523 on the aluminum foil to prepare the posit...

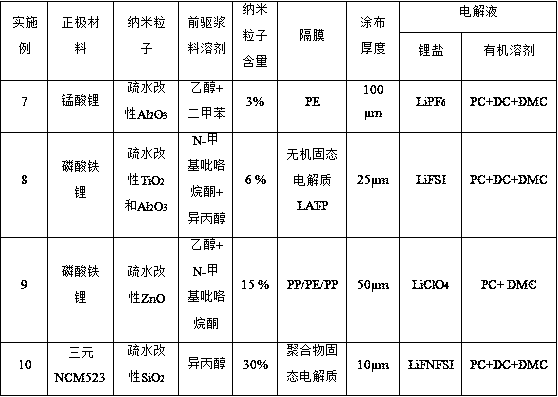

Embodiment 6

[0048] The preparation method of lithium secondary battery is as follows:

[0049] (1) Hydrophobic SiO 2 Preparation of nanoparticles: the SiO 2 Nanoparticles and silane coupling agent were ultrasonically dispersed in ethanol, stirred at 70°C for 6 h, separated by centrifugation or filtration, washed with ethanol, and finally dried in vacuum.

[0050] (2) Coating the positive electrode material nickel-cobalt-manganese ternary material NCM523 on the aluminum foil to prepare the positive electrode sheet;

[0051] (3) Composite lithium metal on copper foil by electroplating or rolling to prepare negative electrode sheet;

[0052] (4) Hydrophobic nano-SiO 2 The particles are added into the organic solvent and fully stirred to prepare the nanoparticle precursor slurry. The mass fraction of the nanoparticles in the organic solvent is 6%, and the organic solvent used in the precursor slurry is ethanol.

[0053] (5) Double-sidedly coat the nanoparticle precursor slurry prepared in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com