In-situ synthesized Pt/MnO2@Mn3O4 catalyst for catalytic combustion of VOCs (Volatile Organic Compounds) as well as preparation method and application of in-situ synthesized Pt/MnO2@Mn3O4 catalyst

An in-situ synthesis and catalytic combustion technology, which is applied in the direction of catalyst activation/preparation, combustion methods, metal/metal oxide/metal hydroxide catalysts, etc., can solve the problem of further improvement of catalytic activity and stability, increase of application cost, Problems such as complex process, to achieve good industrial application potential, low loading, and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] In situ synthesis of Pt / MnO 2 @Mn 3 o 4 Catalyst preparation:

[0022](1) Dissolve 0.02mol of potassium permanganate in 35mL of deionized water and stir vigorously in a 60°C water bath; dissolve 0.036mol of oxalic acid in 35mL of deionized water to obtain an oxalic acid solution; while stirring, dissolve the oxalic acid solution Add dropwise to the potassium permanganate solution, mix and stir at 60°C for 30min; then transfer the mixed solution to a reaction kettle and react at 180°C for 12h. The reacted precipitate was washed by centrifugation with deionized water and absolute ethanol, dried in an oven at 80°C for 12h, and then calcined in a muffle furnace at 400°C for 5h to obtain MnO 2 ;

[0023] (2) Take 0.6g of prepared MnO 2 Disperse in 8 mL of deionized water, add 0.8 mL of H with a concentration of 0.0193 mol / L 2 PtCl 6 solution, stirred at room temperature for 60min; prepare 0.005mol / L NaBH 4 solution, take 0.95 mL of the solution and add it to the afor...

Embodiment 2

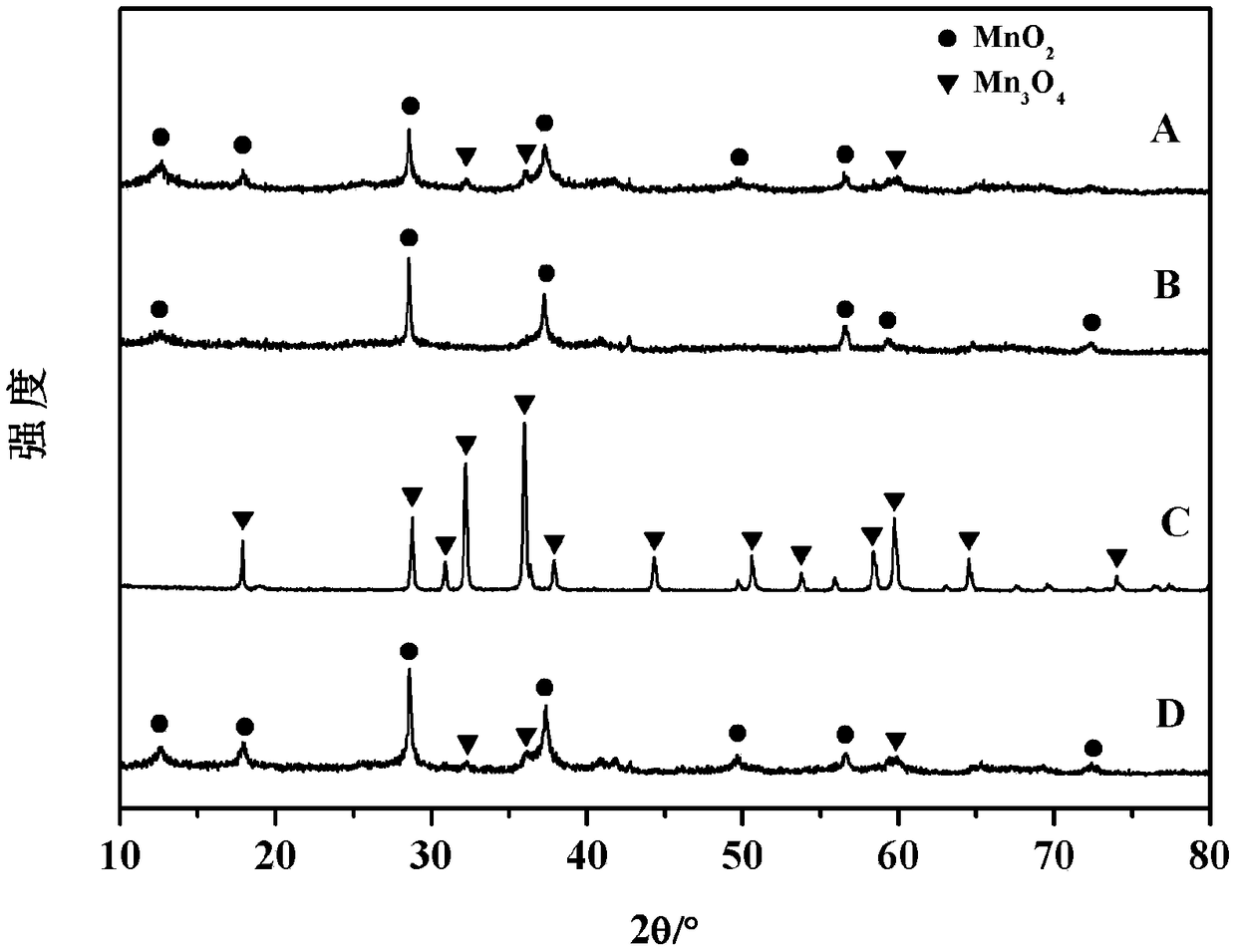

[0033] Carry out X-ray diffraction test to the catalyst A prepared by embodiment 1 and comparative example 1-3, B, C, D, obtain corresponding XRD spectrogram, the result is as follows figure 1 shown. All catalysts have no diffraction peak of Pt. The catalysts of Example 1 and Comparative Example 3 are shown as MnO 2 and Mn 3 o 4 The mixed phase of Comparative Examples 1 and 2 were only MnO 2 and Mn 3 o 4 Corresponding diffraction peaks.

Embodiment 3

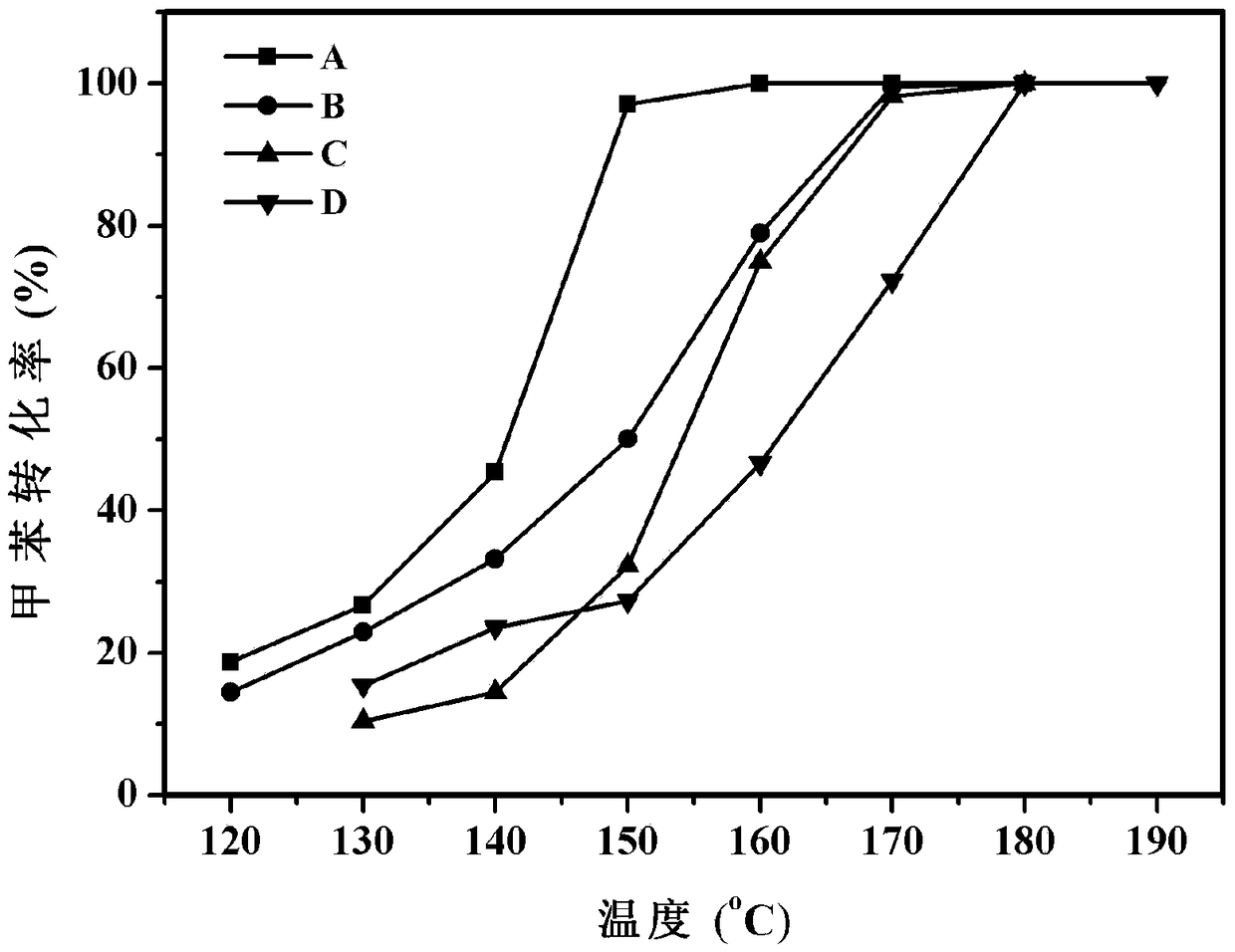

[0035] The catalyst obtained in Example 1 and Comparative Examples 1-3 is tested for toluene catalytic combustion activity. The device used is a self-made fixed-bed continuous microreactor, and the gas chromatography GC 7900 equipped with an FID detector is used for quantitative analysis of toluene before and after the oxidation reaction. concentration. The specific conditions of the test include: the initial concentration of toluene is 500ppm, argon is used as the balance gas, and the reaction gas space velocity is 24000h -1 ; The chromatographic column is a special column for benzene series, the column temperature is 80°C during detection, and the detector temperature is 200°C. The reactivity of each catalyst is as figure 2 As shown, the activity of catalyst A is the best, and the removal rate of toluene can reach 97% at 150°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com