Online precise control method for flattening parameters of microscale abrasive particles

A control method and micro-scale technology, applied in the direction of workpiece feed motion control, program control, general control system, etc., can solve the problems of high cost of robot vision system, error of abrasive grain shape characteristic value, and micro abrasive grain image distortion, etc. problems, to avoid the detection and data processing process, to meet the processing quality requirements, and to achieve the effect of flexible adjustment methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

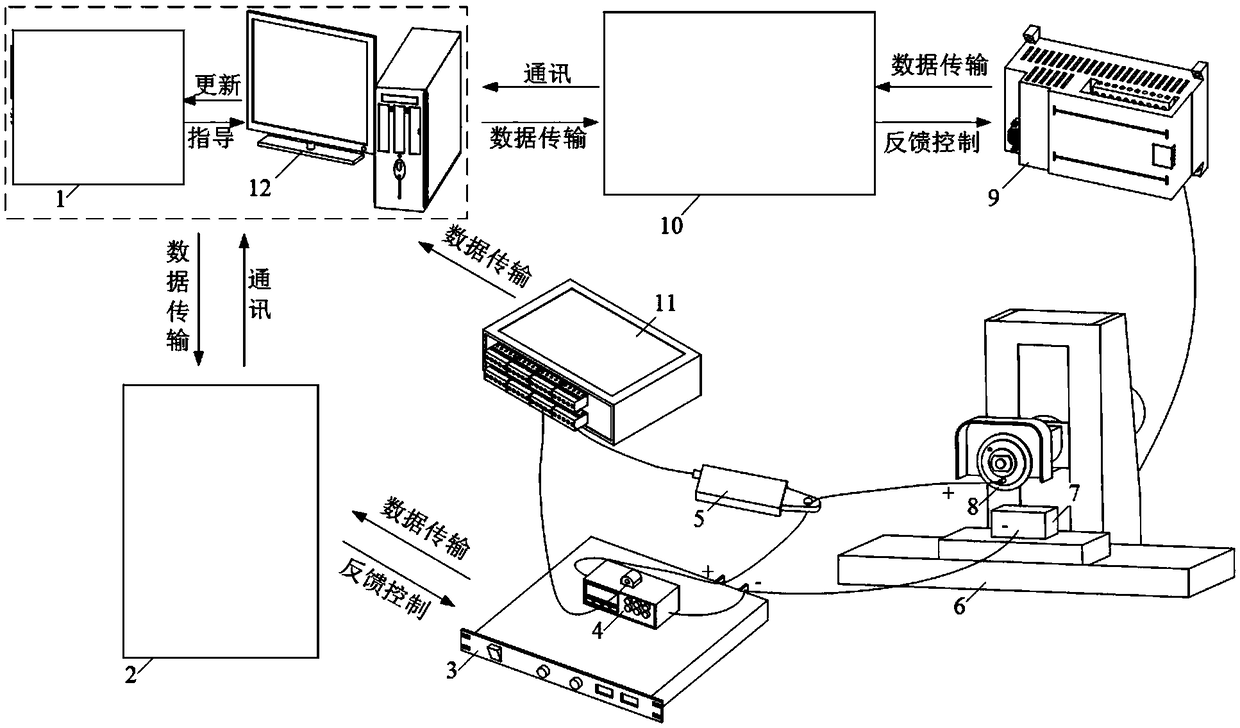

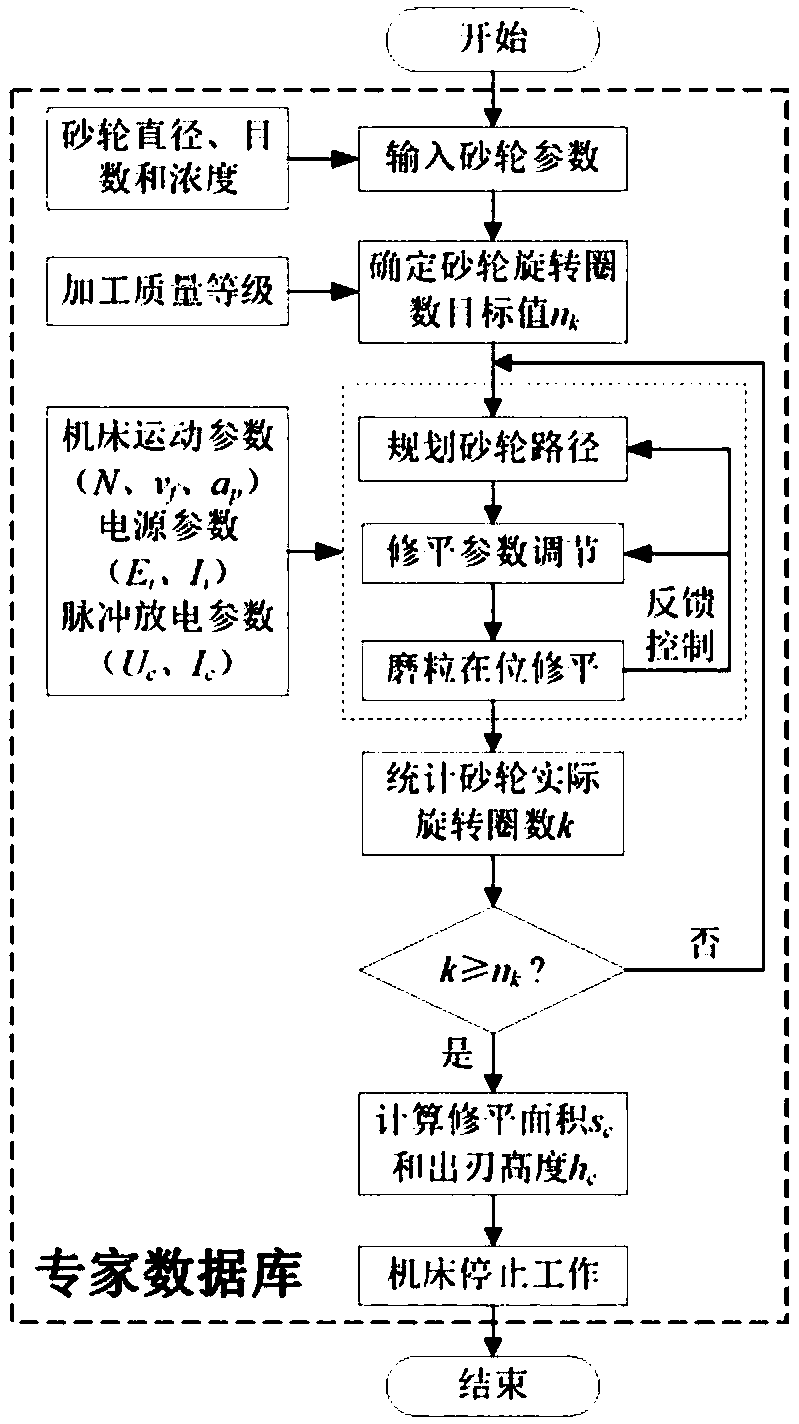

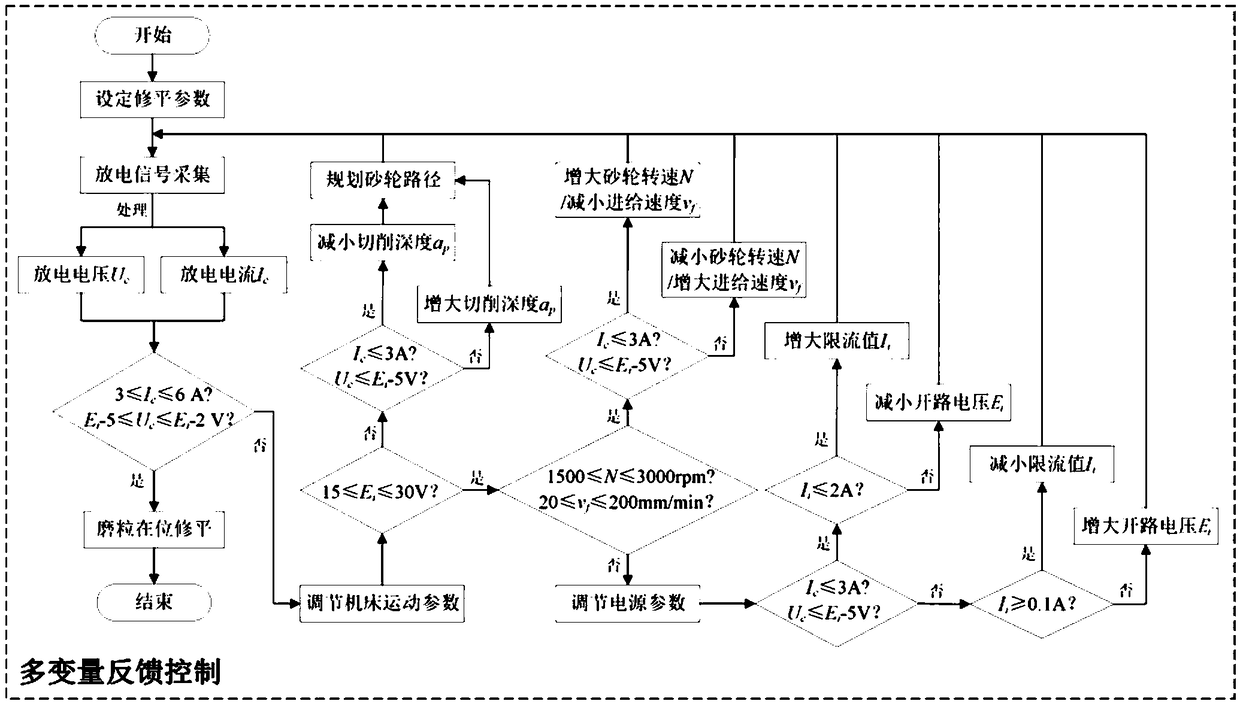

Method used

Image

Examples

Embodiment 1

[0081] In the flattening experiment of micro-abrasive particles, #46 diamond grinding wheel (diameter D=150mm, bronze bond) and iron electrode (45 steel) were fixed on the CNC machine tool (SMART 818), and graphite brushes, Oscilloscope (DS1102E), DC power supply (DCS80), voltage and current sensors (RP1000D and RP1001C) are connected to form a discharge circuit. In order to generate different spark discharges, the open circuit voltage E i =25V, current limit value I i =0.1A, grinding wheel speed N=2400rpm, table feed speed v f =80mm / min, axial feed △z=1mm, cutting depth a p =1 and 5 μm, and the smoothing time of each group was 20 hours.

[0082] Pulse discharge waveform tracking and chips such as microabrasive particle smoothing Figure 5 As shown in (a) and 5(b), according to the constant voltage and constant current conversion principle of the power supply, during the leveling process, the cutting depth a p The increase of the electric spark discharge will gradually co...

Embodiment 2

[0091] Similarly, fix the #46 diamond grinding wheel (diameter D=150mm, bronze bond) and the iron electrode (45 steel) on the CNC machine tool (SMART 818), and connect it with the graphite brush, oscilloscope (DS1102E), DC Power supply (DCS80), voltage and current sensors (RP1000D and RP1001C) are connected to form a discharge circuit, with open circuit voltage E=25V, grinding wheel speed N=2400rpm, cutting depth a p = 1μm (spark discharge), the axial feed Δz = 1mm for experiments. In order to control the discharge current and voltage in the range of 3~6A and 19~23V respectively, adjust the feed speed v of the table during the leveling process f (initial value v f =80mm / min) or current limiting value (initial value I i =0.1A), and the specified number of rotations reaches 1.26×10 6 After the second time, the morphology of the micro-abrasive particles on the grinding wheel section was detected.

[0092] Such as Figure 8 As shown in (a) and 8(b), the cutting edge trimming ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com