A preparation method of super-tough rigid polyvinyl chloride pipe compounding material

A rigid polyvinyl chloride and pipe technology is applied in the field of preparation of special materials for plastic pipes, which can solve the problems of affecting compatibility, affecting the color and mechanical properties of composite materials, affecting the weather resistance of elastomers, etc., so as to improve the compatibility. , The effect of improving the weather resistance and reducing the number of

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] 100 parts by weight of polyvinyl chloride and 4 parts by weight of acrylonitrile-butadiene-styrene terpolymer, 1 part by weight of methyl methacrylate, 200 parts by weight of water, and 0.2 parts by weight of sodium lauryl sulfate were added to the In the reactor with cooling water and nitrogen inlet and outlet, after passing nitrogen for 10 minutes, start the ultrasonic generator for 20-30 minutes, and the reaction temperature is 20-30°C. After the reaction, the water was filtered and dried.

[0026] Add the above dry material into a high-speed mixer, then successively add 10 parts by weight of nano-calcium carbonate, 3 parts by weight of calcium-zinc stabilizer, 3 parts by weight of acrylic resin processing aids, 1 part by weight of calcium stearate, 0.5 parts by weight Paraffin wax, mixed to 110-120 ° C, discharged and cooled, to obtain the super-tough rigid polyvinyl chloride pipe compound of the present invention.

Embodiment 2

[0028] 100 parts by weight of polyvinyl chloride and 7 parts by weight of acrylonitrile-butadiene-styrene terpolymer, 1.5 parts by weight of methyl methacrylate, 200 parts by weight of water, and 0.3 parts by weight of sodium lauryl sulfate were added to the In the reactor with cooling water and nitrogen inlet and outlet, after passing nitrogen for 10 minutes, start the ultrasonic generator for 20-30 minutes, and the reaction temperature is 20-30°C. After the reaction was completed, the water was filtered and dried.

[0029] Add the above dry material into a high-speed mixer, then successively add 15 parts by weight of nano-calcium carbonate, 3 parts by weight of calcium-zinc stabilizer, 3 parts by weight of acrylic resin processing aids, 1 part by weight of stearic acid, and 0.5 parts by weight of oxidation Polyethylene wax, mixed to 110-120°C, discharged and cooled, to obtain the super-tough rigid polyvinyl chloride pipe compound of the present invention.

Embodiment 3

[0031] 100 parts by weight of polyvinyl chloride and 10 parts by weight of acrylonitrile-butadiene-styrene terpolymer, 2 parts by weight of methyl methacrylate, 200 parts by weight of water, and 0.5 parts by weight of sodium lauryl sulfate are added to In the reactor with cooling water and nitrogen inlet and outlet, after passing nitrogen for 10 minutes, start the ultrasonic generator for 30 minutes, and the reaction temperature is 20-30°C. After the reaction was completed, the water was filtered and dried.

[0032] Add the above dry material into a high-speed mixer, then successively add 20 parts of nano-calcium carbonate, 1 part by weight of organic tin stabilizer, 3 parts by weight of acrylic resin processing aid, 1 part by weight of calcium stearate, 0.5 parts by weight of paraffin wax , mixed to 110-120°C, discharged and cooled to obtain the super-tough rigid polyvinyl chloride pipe compound of the present invention.

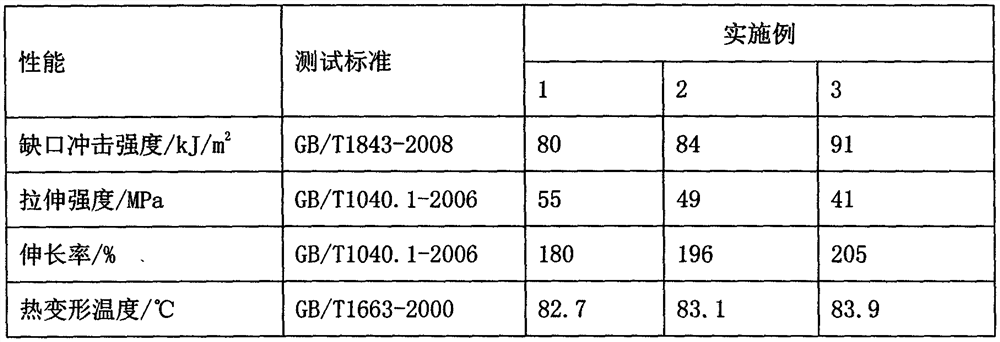

[0033] Several key properties of the pipe prepared b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com