Stacking heat treatment process of iron-based high temperature alloy and performance research

An iron-based superalloy and process technology, which is applied in the field of iron-based superalloy accumulation heat treatment process and its performance research, can solve the problems of backward mold manufacturing methods, few new mold materials, and backward hot work molds, and achieve a considerable period of life. , the parts are intact, the effect of saving expenses

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

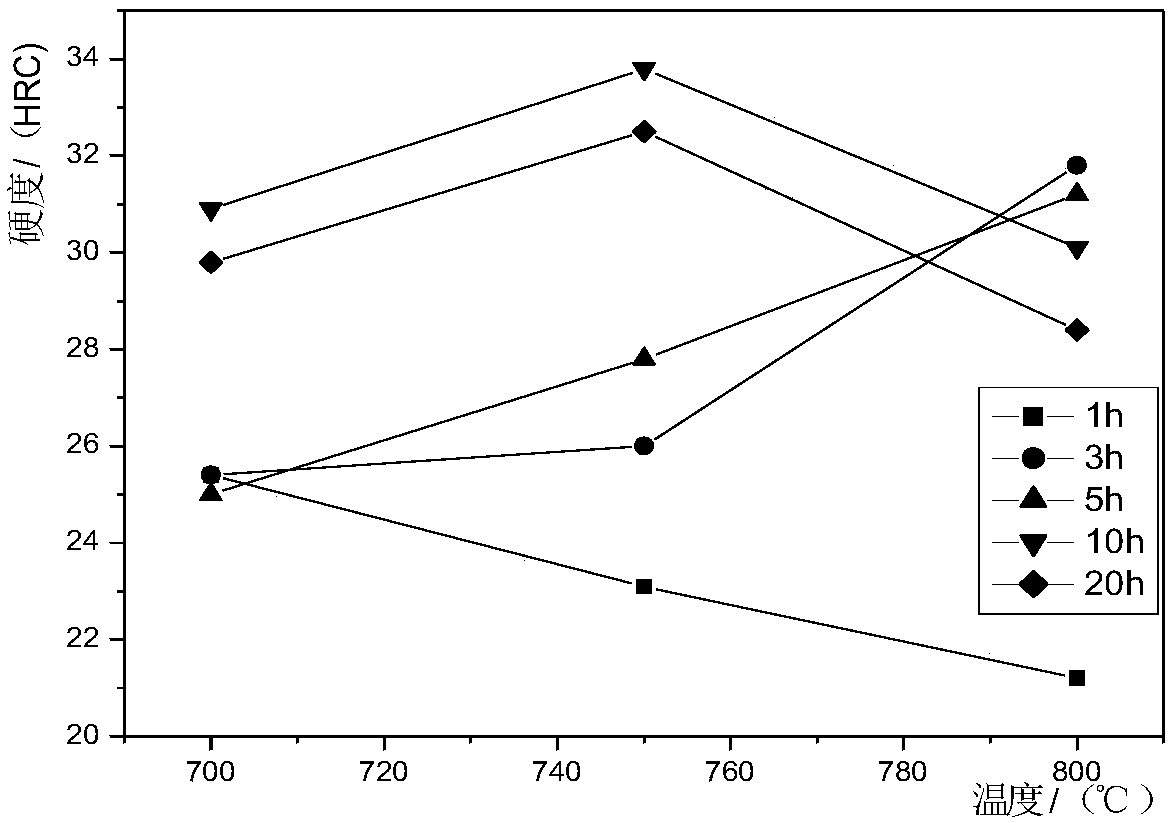

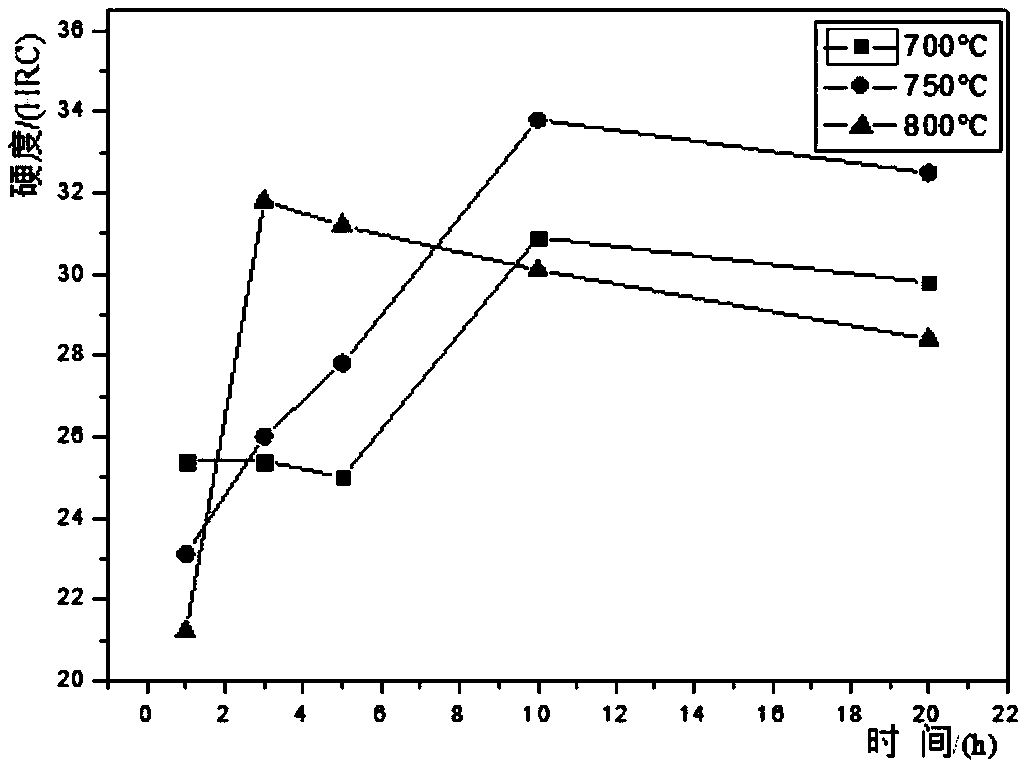

[0031] Determination of heat treatment process parameters:

[0032] The performance of superalloys mainly depends on its chemical composition and structure. When the alloy composition is constant, the factors affecting the structure of the alloy include smelting, casting, plastic deformation and heat treatment process, and the heat treatment process is more sensitive to the influence of the alloy structure. Different heat treatments can make the grain size of the alloy, the strengthening phase, the number and particle size of the dissolved and precipitated phases, and even the state of the grain boundary. Therefore, an alloy has different structures after different heat treatments, and thus has different properties and uses. Superalloys with good thermal stability maintain high hardness and strength under high temperature conditions. Therefore, it is required that in a high-temperature working environment, the second phase is precipitated and the second phase is fine and disp...

Embodiment 2

[0035] The chemical composition of the overlay welding alloy D3 used in the present embodiment is as shown in table 1:

[0036] Table 1 Design composition (%) of surfacing alloy D3

[0037]

[0038]

[0039] 1) The role of each element in the alloy

[0040] During the heating and heat preservation process of metal materials, there will be two changes: one is the transformation of retained austenite into martensite, and the other is the aggregation, growth and precipitation of alloy elements, resulting in secondary hardening. Obviously, under the thermal stability test process, if the material can maintain a high "secondary hardening" performance, it will have high thermal stability.

[0041]The alloying element W is a strong carbide-forming element. In the temperature range of 500 ° C to 600 ° C, martensite decomposes and precipitates W, C and WC carbides. This type of carbide has a high melting point and high thermal stability. It is difficult to dissolve into solid s...

Embodiment 3

[0055] Performance Testing:

[0056] A total of 21 samples were prepared, of which 2 were the original samples in the surfacing state, 15 were heat-treated samples, and the remaining 4 were used as spares, and all of them were clearly marked.

[0057] 1. For hardness analysis, use a Rockwell hardness tester. The type of indenter used in the test is a diamond cone, and the scale is HRC. The Rockwell hardness value is calculated based on the indentation depth h. The larger the H value, the lower the hardness value; otherwise, the higher the Rockwell hardness value is calculated: HR=(k-h) / 0.002, k is 0.2mm .

[0058] 2. Metallographic analysis: erode or rub the polished sample surface in a chemical etchant until the surface loses luster. The chemical etchant is triacid ethanol, and its composition is: 10% nitric acid, 25% hydrochloric acid, % ethanol, 15% supersaturated picric acid, take metallographic photos after 4-5 minutes of corrosion, and then analyze the structure and ph...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com