Method for preparing anti-corrosion coating by means of laser cladding technology

A technology of anti-corrosion coating and laser cladding, which is applied in the direction of coating, metal material coating process, etc., can solve the problems of poor corrosion resistance, achieve the effect of smooth cladding layer surface, improve corrosion resistance, and improve quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

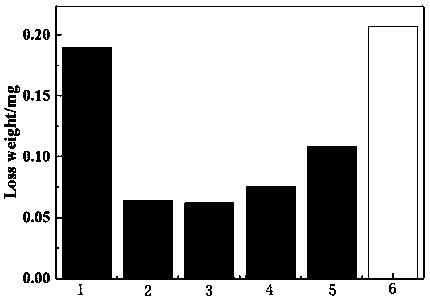

Embodiment 1

[0039] This embodiment provides a method for preparing an anti-corrosion coating using laser cladding technology, which specifically includes the following steps:

[0040] S1. Cladding substrate pretreatment: use Q960 steel as the cladding substrate, polish its surface with 600-grit sandpaper, and then use 95% ethanol solution to clean the oil and rust on the surface, and the cleaning time is 5 minutes;

[0041] S2. Drying the Stellite 6 alloy powder, the process parameters of the drying treatment are: the drying temperature is 80° C., the drying time is 30 minutes, and the particle size of the Stellite 6 alloy powder is 50 μm;

[0042] S3. Using STAUBLTX90 CNC laser combined with coaxial powder feeding method to clad Stellite 6 alloy powder on the surface of Q960 steel, and rapidly cool at room temperature to form a layer of alloy coating, which is a wear-resistant and corrosion-resistant composite coating;

[0043] Among them, the power of the laser is 450W, the selected spo...

Embodiment 2

[0045]This embodiment provides a method for preparing an anti-corrosion coating using laser cladding technology, referring to the preparation method of Embodiment 1, the difference from Embodiment 1 is that in step S3, the power of the laser is 500W.

Embodiment 3

[0047] This embodiment provides a method for preparing an anti-corrosion coating using laser cladding technology, referring to the preparation method of Embodiment 1, the difference from Embodiment 1 is that in step S3, the power of the laser is 550W.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Microhardness | aaaaa | aaaaa |

| Self-corrosion potential | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com