Ferro-nickel diselenide, as well as preparation method and application thereof

A compound, diselenide technology, which is applied to electrodes, electrolytic inorganic material coating, electrolysis process, etc., can solve the problems of difficulty in simultaneously realizing the catalytic stability and catalytic activity of hydrogen production and oxygen production, and achieves good uniformity and simple preparation process. , the effect of shortening the reaction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~12

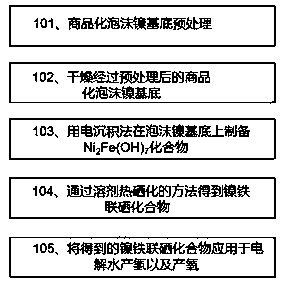

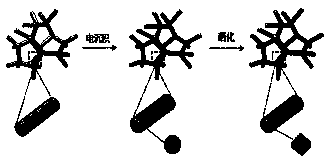

[0055] A nickel-iron diselenide compound, the chemical formula of the nickel-iron diselenide compound is NixFe1-xSe 2 . The preparation method of nickel-iron diselenide compound is:

[0056] S1. With Fe(NO 3 ) 3 9H 2 O and Ni(NO 3 ) 2 ·6H 2 O as the source of iron and nickel, Fe(NO 3 ) 3 9H 2 O and Ni(NO 3 ) 2 ·6H 2 The molar ratio of O is 1:1, and Ni is grown on the foamed nickel substrate by electrodeposition. 2 Fe(OH) 7 Compound, prepared to get Ni 2 Fe(OH) 7 Covered foamed nickel, the electrodeposition method is reacted by the electrochemical workstation (Shanghai Chenhua Instrument Co., Ltd., CHI 660E). The place in the electrochemical workstation is the dried nickel foam as the working electrode, Ag / AgCl (3M KCl) The electrode is used as a reference electrode, and the platinum plate electrode is used as a counter electrode;

[0057] S2. Ni prepared from S1 2 Fe(OH) 7 The covered foam nickel, selenium powder, NaOH, N, N-dimethylformamide, and hydrazine ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com