One-way tearable fabric for automobile harness tape

A technology for automotive wiring harnesses and fabrics, which is applied in liquid/gas/steam textile material processing, fabric surface trimming, textile material processing, etc. effect, improved efficiency, improved tear performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

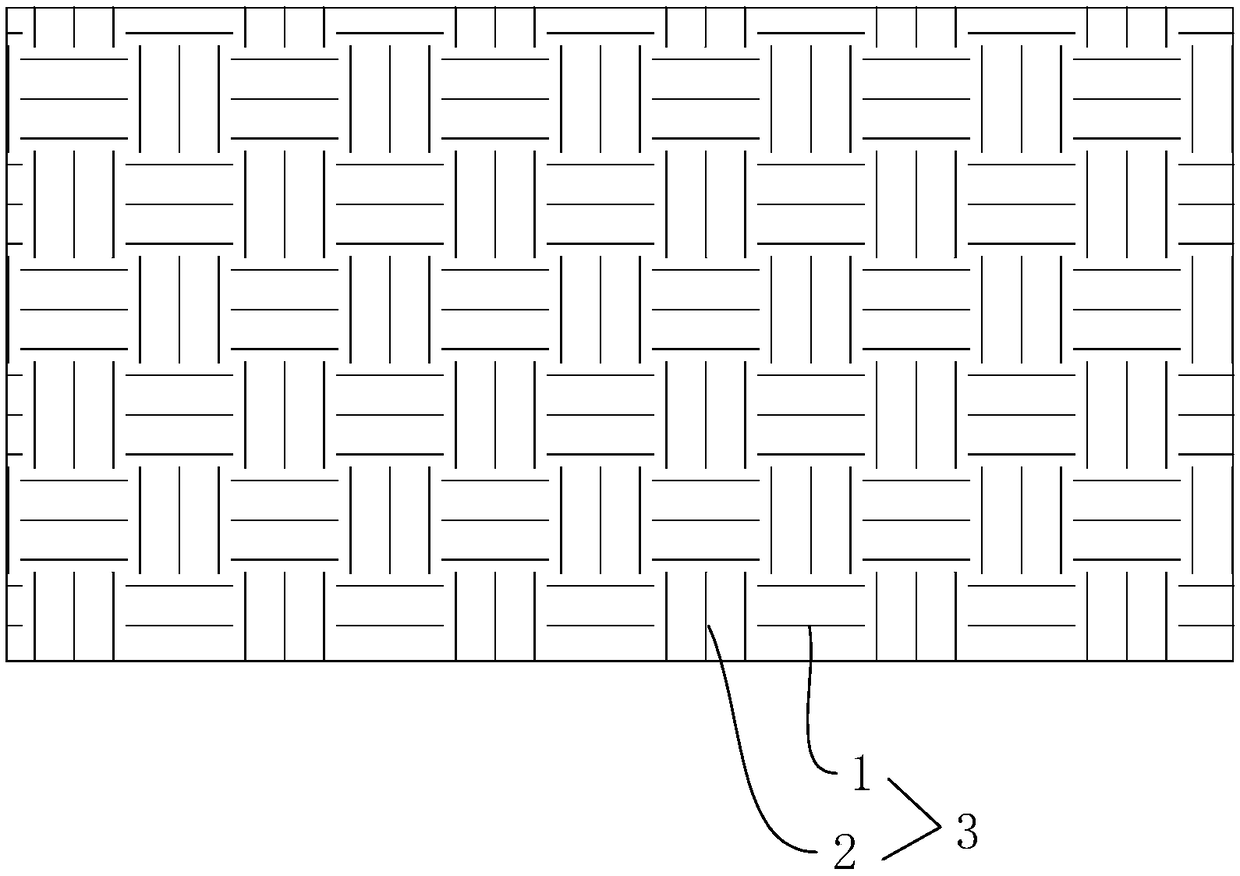

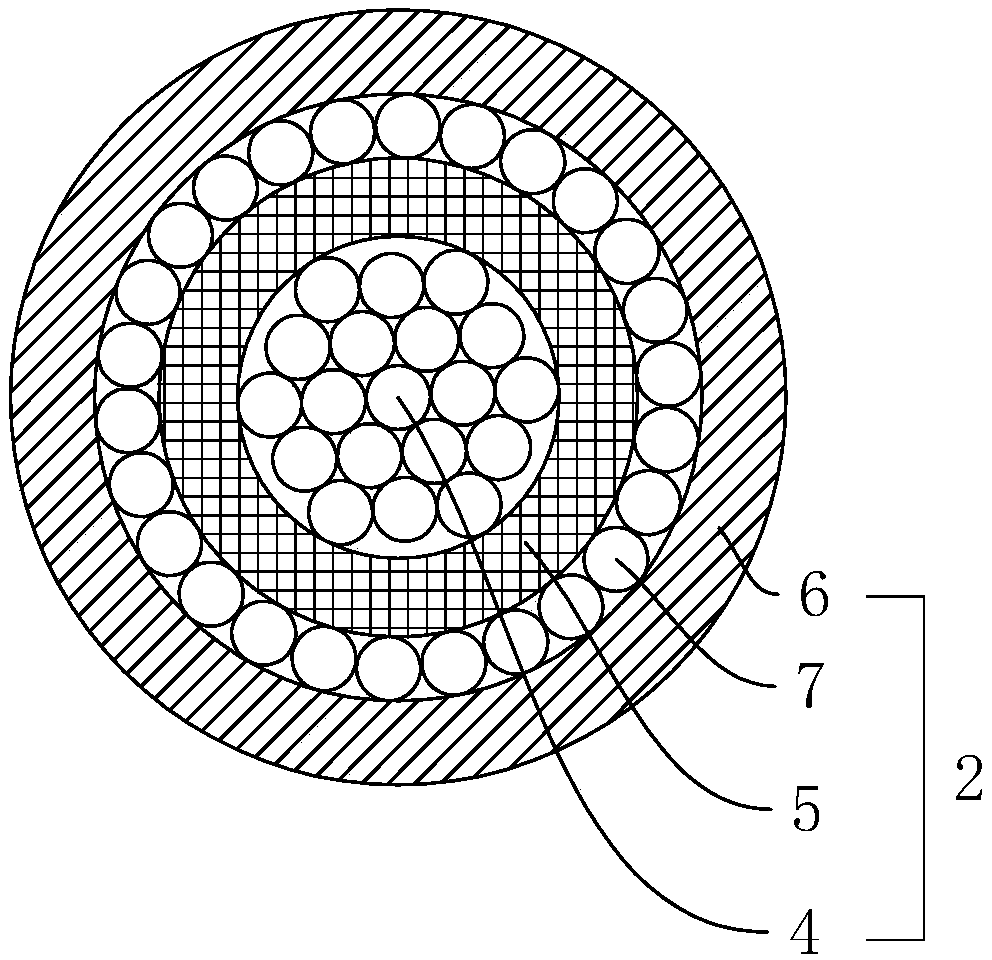

[0040] Embodiment 1: A kind of unidirectional tearable fabric for automobile wiring harness tape, such as figure 1 As shown, it includes a fabric body 3 interlaced with warp yarn 1 and weft yarn 2. Warp yarn 1 is a modified polyester low-elastic yarn, wherein the modified polyester low-elastic yarn is obtained by adding hydrophilic It is obtained by modifying the third monomer and / or the fourth monomer of the group. Secondly, the hydrophilic group, also known as the oleophobic group, has an atomic group that is soluble in water or easily compatible with water. It attracts water molecules or dissolves in water, and such molecules form solid surfaces that are easily wetted by water. Among them, the hydrophilic group includes carboxylic acid group, sulfonic acid group, phosphoric acid group, amino group, quaternary ammonium group, ether group, hydroxyl group, carboxylate and block polyether that have been composed of oxygen-containing groups. Therefore, by increasing the hydrop...

Embodiment 2

[0051] Embodiment 2: A kind of unidirectional tearable fabric for automobile wiring harness tape, the difference from Embodiment 1 is: in the step S1 of its processing method, after the selection of the texture and material of the fabric body 3 is completed, then A number of fabric bodies 3 with a total cloth weight of 130-145g are placed in the same compartment for processing with cylinders.

Embodiment 3

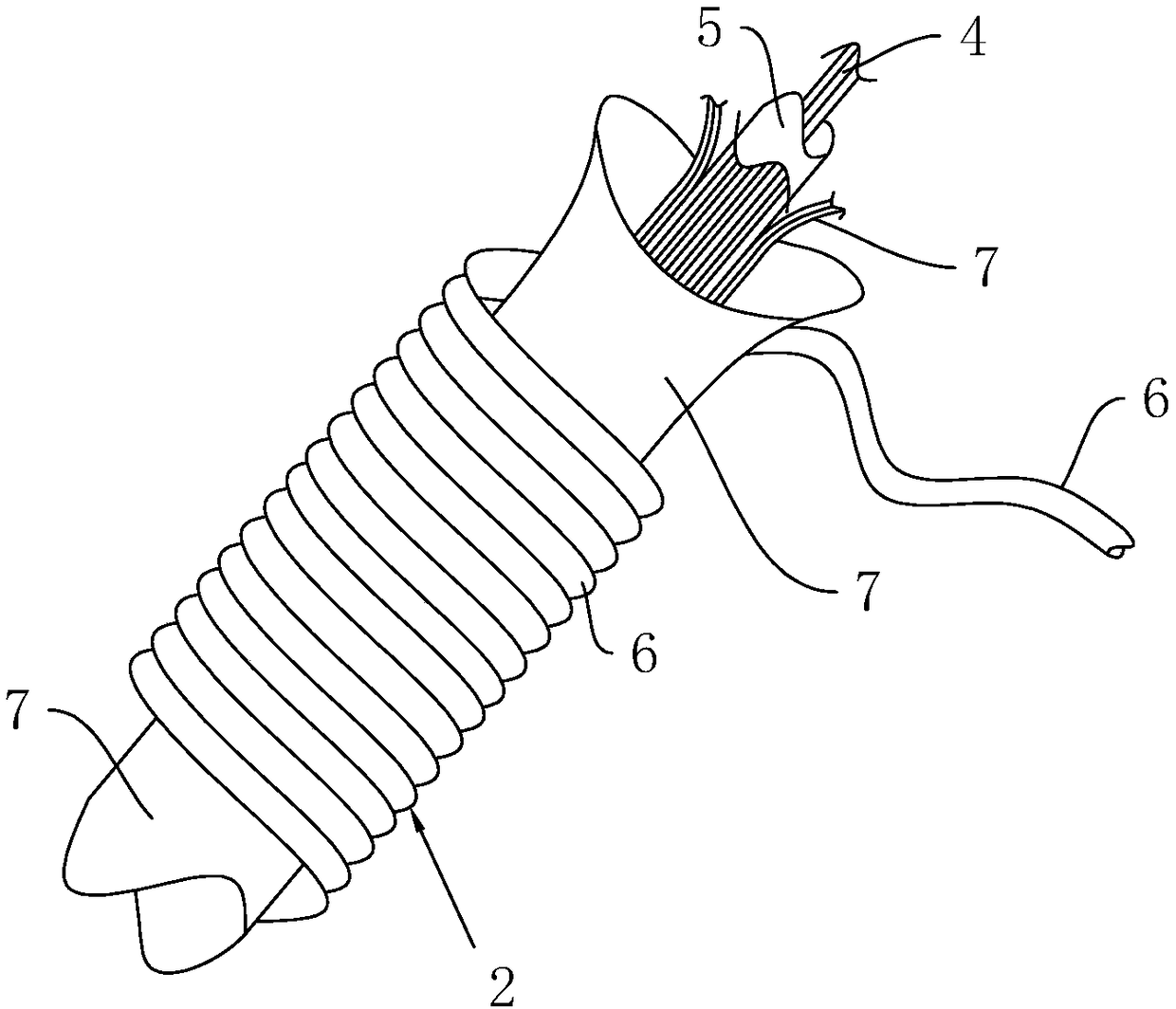

[0052] Example 3: A one-way tearable fabric for automotive wiring harness tape, the difference from Example 1 is that in step S1 of the processing method, the front and back sides of the fabric body 3 after the rolling process are processed simultaneously. Alkaline rolling treatment, then transported by the discharge mechanism of the cold stacker and wound on the roller shaft of A-frame 2; then use plastic packaging cloth to seal and wrap the outer fabric body 3 after alkali rolling for fermentation and desizing treatment ;

[0053] Then place several A-frames in parallel, and simultaneously drive several A-frames to rotate horizontally and at a constant speed through the fermentation linkage mechanism, and seal and ferment for no less than 24 hours;

[0054] Then remove the plastic wrapping cloth on the outside of the fabric body 3, and then push the A-frame 2 to the feed inlet of the washing machine; The rolls are squeezed dry and rewound on A-frame three rolls.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com