Preparation method of bionic phospholipid membrane with controllable shape

A technology of biomimetic phospholipids and phospholipids, which is applied in the direction of using substances to absorb and weigh, can solve the problems of consuming resources and increasing experimental procedures, and achieves the effects of saving resources, simple operation process, good stability and reproducibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

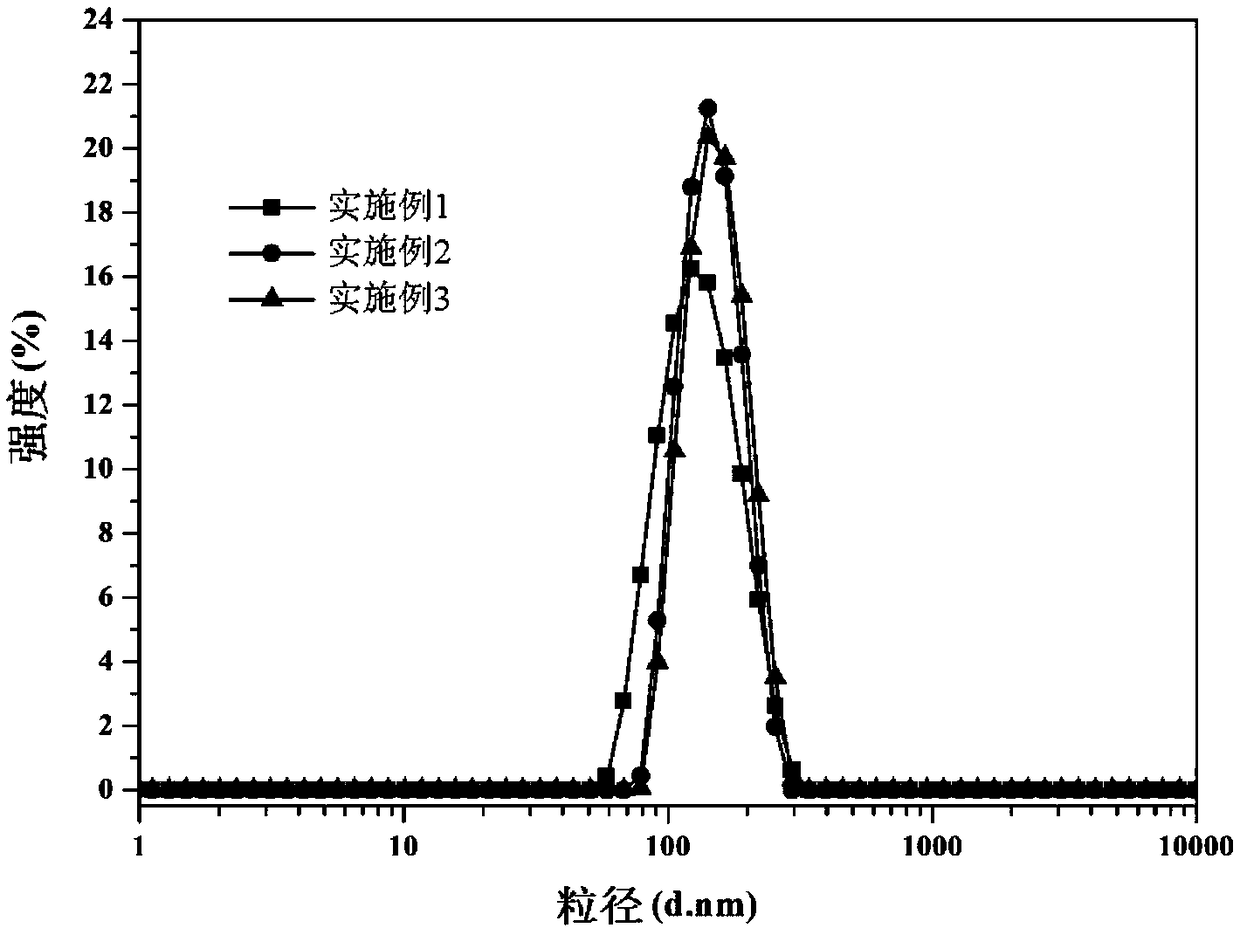

[0036] The preparation of a kind of biomimetic phospholipid membrane (phospholipid bilayer membrane) of the present embodiment, concrete preparation steps are as follows:

[0037] (1) DPPC (dipalmitoylphosphatidylcholine) and cholesterol were weighed and mixed at a molar ratio of 7:2, and dissolved in chloroform. The organic solvent was evaporated on a rotary evaporator to obtain a phospholipid film. Add Tris buffer solution without metal cations, and hydrate at 65°C for 1h. Sonicate for about 30 min to obtain a vesicle suspension. The resulting vesicle suspension was extruded 11 times through a polycarbonate track-etched membrane (pore size 100 nm) using a LiposoFast handheld liposome extruder to obtain a phospholipid vesicle solution.

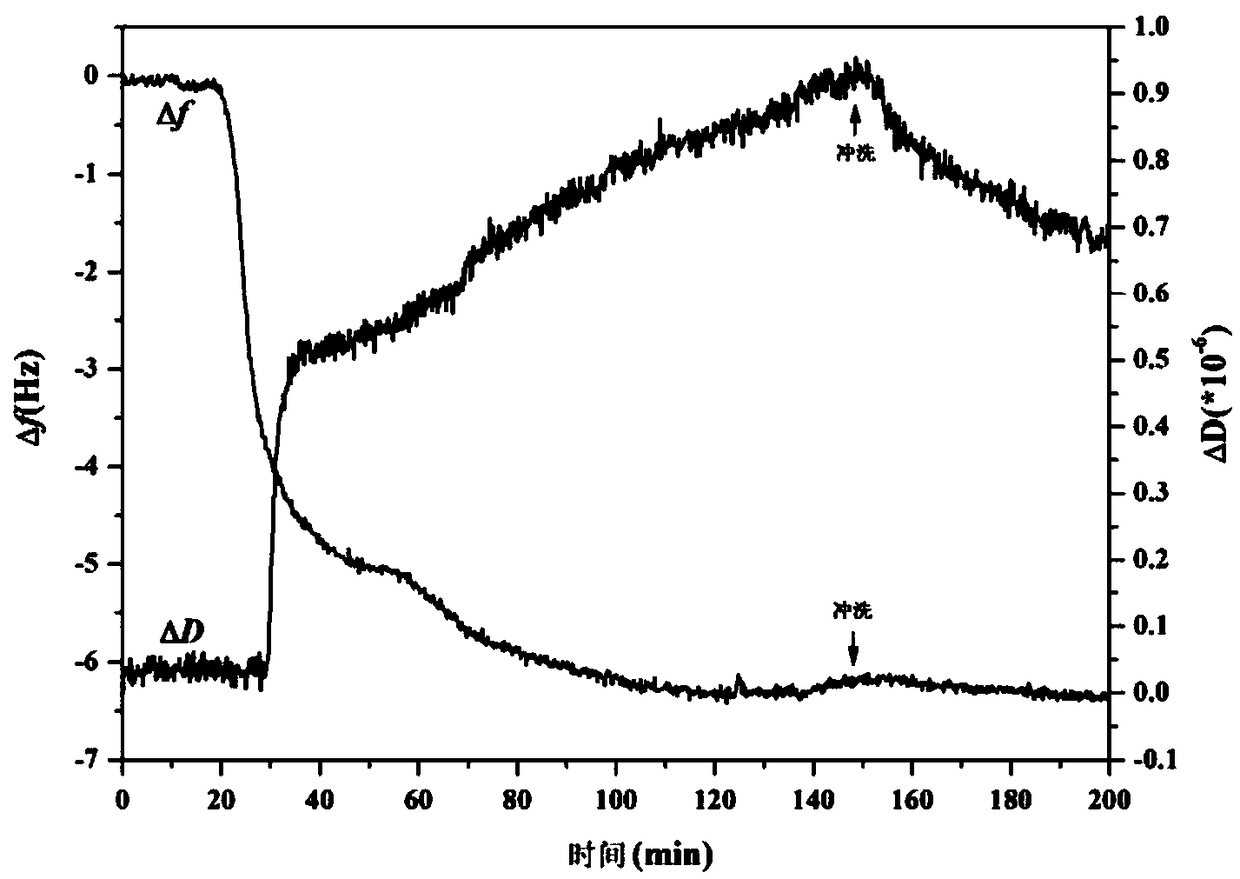

[0038] (2) Use a hydration solution (Tris buffer solution without metal cations) to dilute the vesicle solution to a phospholipid concentration of 0.05 g / L. The diluted vesicle solution was flowed over the surface of a gold chip (a gold ch...

Embodiment 2

[0041]The preparation of a biomimetic phospholipid membrane (supported vesicle membrane with a vesicle particle size in the range of 100-200nm) of this embodiment, the specific preparation steps are as follows:

[0042] (1) DPPC (dipalmitoylphosphatidylcholine) and cholesterol were weighed and mixed in a molar ratio of 4:1, and dissolved in chloroform. The organic solvent was evaporated on a rotary evaporator to obtain a phospholipid film. Add 0.5mol / L NaCl in Tris buffer solution, and hydrate at 65°C for 1h. Sonicate for about 30 min to obtain a vesicle suspension. The resulting vesicle suspension was extruded 11 times through a polycarbonate track-etched membrane (pore size 100 nm) using a LiposoFast handheld liposome extruder to obtain a phospholipid vesicle solution.

[0043] (2) Dilute the vesicle solution to a phospholipid concentration of 0.1 g / L using a hydration solution (0.5 mol / L NaCl in Tris buffer solution). The diluted vesicle solution flowed over the surface ...

Embodiment 3

[0046] The preparation of a biomimetic phospholipid membrane (supported vesicle membrane with a vesicle particle size in the range of 200-800nm) in this embodiment, the specific preparation steps are as follows:

[0047] (1) DMPC (dimyristoylphosphatidylcholine), DPPC (dipalmitoylphosphatidylcholine) and cholesterol were weighed and mixed in a molar ratio of 10:1:3, and dissolved in chloroform. The organic solvent was evaporated on a rotary evaporator to obtain a phospholipid film. Add 5mmol / L MgCl 2 ·H 2 O aqueous solution, hydrated at 65°C for 1h. Sonicate for about 30 min to obtain a vesicle suspension. The resulting vesicle suspension was extruded 11 times through a polycarbonate track-etched membrane (pore size 100 nm) using a LiposoFast handheld liposome extruder to obtain a phospholipid vesicle solution.

[0048] (2) Use hydration solution (5mmol / L MgCl 2 ·H 2 O in water) to dilute the vesicle solution to a phospholipid concentration of 0.08 g / L. The diluted vesi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| phase transition temperature | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com