A factory full-load test method for large-capacity svg

A test method and large-capacity technology, applied in the power grid field, can solve the problems of high cost and limited utilization of the test platform, and achieve the effects of small footprint, simple structure and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

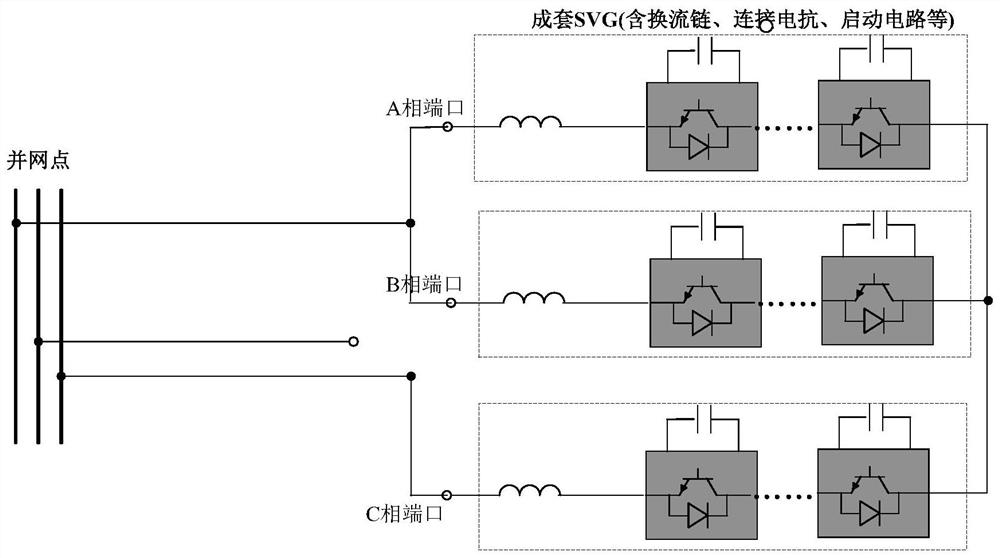

Embodiment approach 1

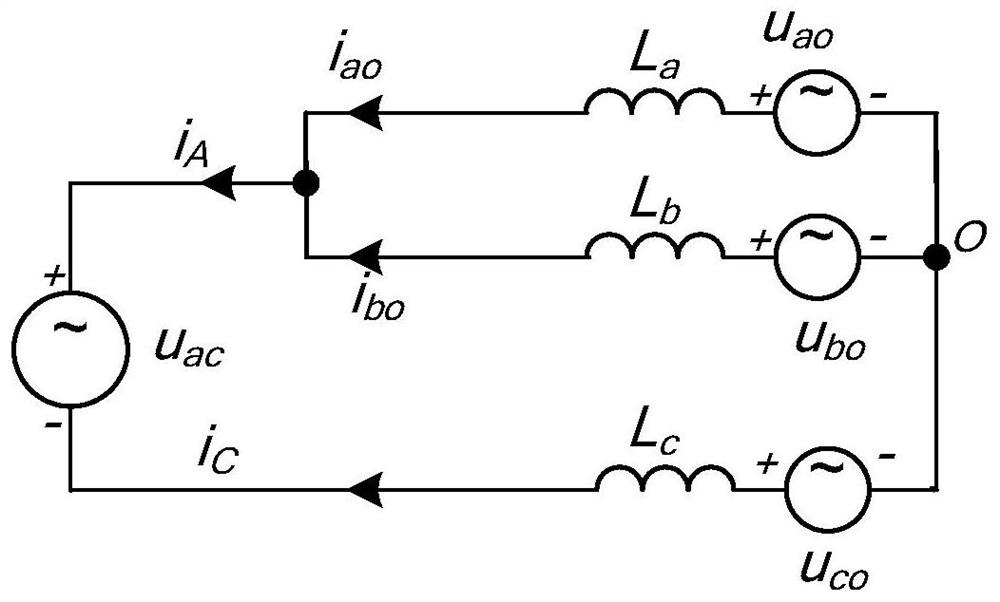

[0024] First, the present embodiment discloses a method for testing full SVG large capacity, comprising: the SVG wherein the two phases short-circuited in series with the third line and the two-phase network, and then to be phase independent control SVG. The two phases are short-circuited configured to output constant current mode, and is a capacitive, an inductive power to achieve a two-phase short-circuiting between the hedge and without external current output, and connected to the internal short between two phases SVG load circuit corresponding to full rated current; At the same time, the third phase is configured to output a constant voltage mode, and the third phase output voltage is equal to the line voltage and outlets ports are shorted and the two-phase rated voltage vector phase difference.

[0025] To facilitate those skilled in the art to fully understand the present embodiment and the method of the above-described configuration architecture, described in further detai...

Embodiment approach 2

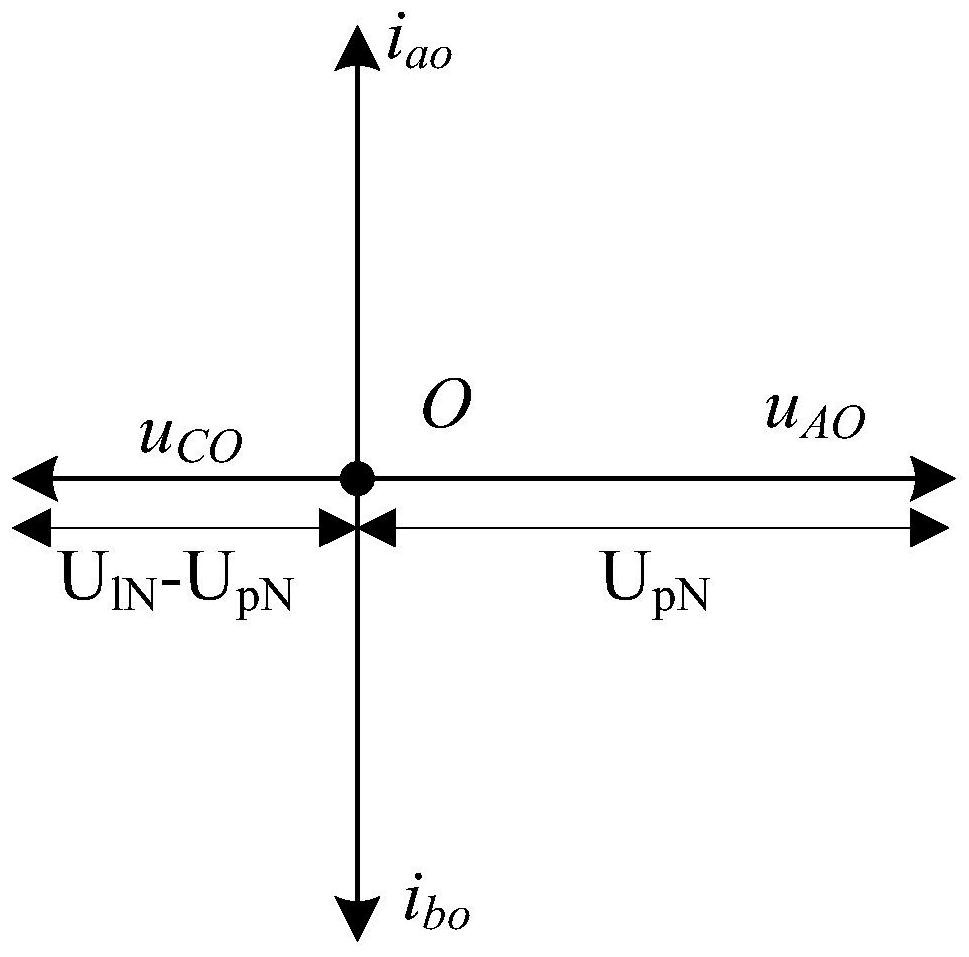

[0045] SVG typical power cells each phase DC bus voltage from the active current regulation components, its hardware wiring test with Embodiment 1, but different voltage and current control. This is because SVG valve power loss due to the switching process during operation, the device is turned on factors such as pressure drop inevitably produce active consumption, if we follow image 3 The voltage-current vector relationship regulation, and ports due to the current identically zero, so that the respective phases valve SVG absorption from the grid is not active, and the two-phase AB manifold due to its own power loss will hardly be unable to maintain a stable DC voltage.

[0046] At this time, SVG voltage and current of each phase of the valve may be controlled as follows: ①C valve phase power to a constant voltage output mode, the amplitude of the output voltage equal to the rated phase voltage and phase lag of the AC line voltage of approximately 150 °, thus the relationship betw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com