Medium cavity substrate integration waveguide structure based on silicon through hole technology and manufacturing technology thereof

A substrate-integrated waveguide and dielectric cavity technology, which is applied in waveguides, waveguide-type devices, circuits, etc., can solve the problems of large loss and hinder the wide application of substrate-integrated waveguides, and achieve the effect of improving resonance extraction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The present invention will be specifically introduced below in conjunction with the accompanying drawings and specific embodiments.

[0042] Firstly, the dielectric cavity substrate integrated waveguide structure based on the through-silicon via technology of the present invention is introduced.

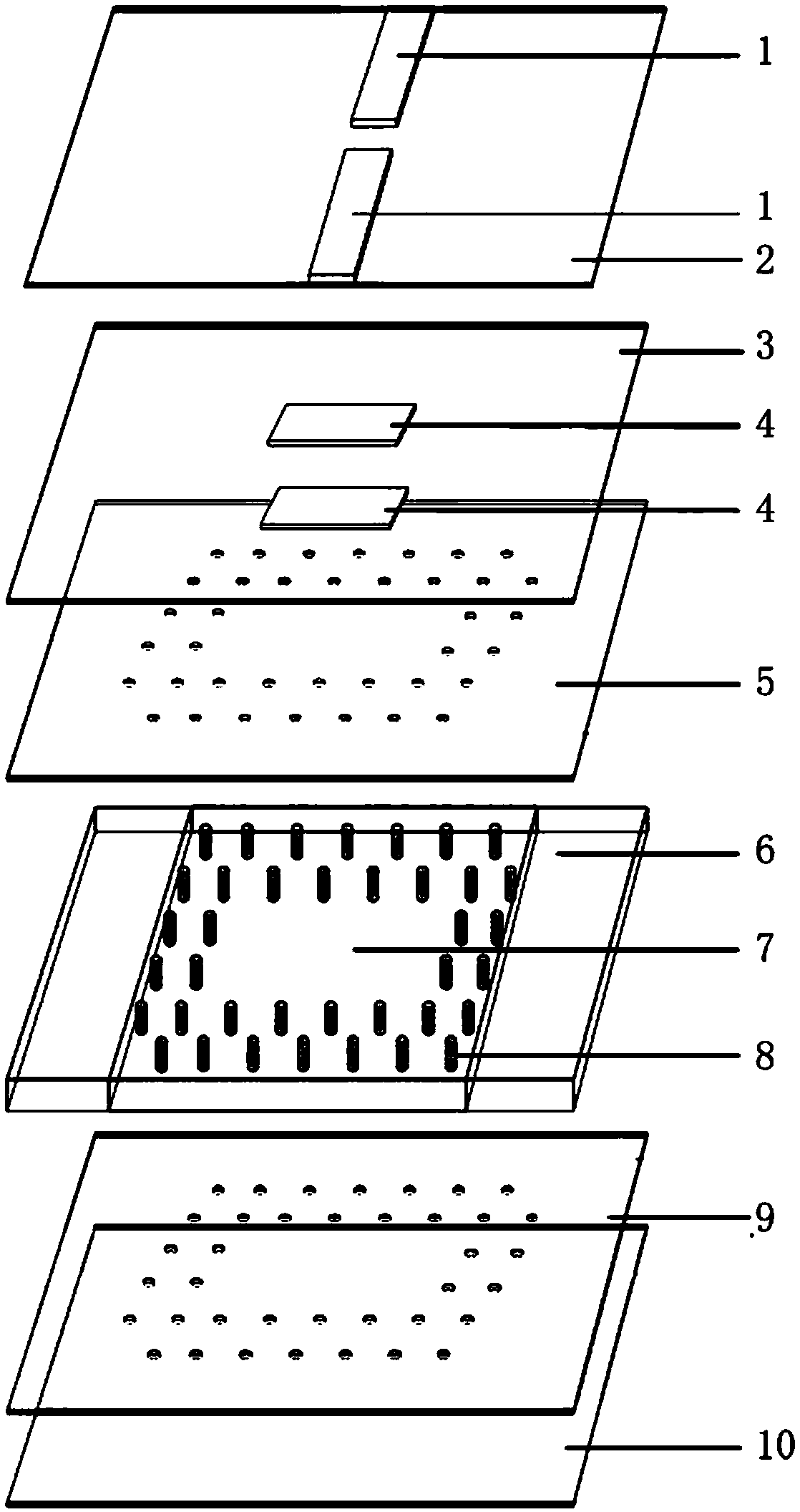

[0043] refer to figure 1, the dielectric cavity substrate integrated waveguide (SIW) structure based on through-silicon via technology of the present invention, which comprises from top to bottom: a top metal interconnect dielectric layer 2, a top ground ground plate 3, and an intermediate metal interconnect dielectric layer 5 , a low-resistance silicon substrate 6 , a bottom metal interconnection dielectric layer 9 and a bottom ground plane 10 .

[0044] 1. The top metal interconnect dielectric layer

[0045] The top metal interconnect dielectric layer 2 is used to electrically isolate the top ground plane 3 from other metal interconnects, and it uses insulating materials s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com