Anti-freezing anti-cracking fireproof water-resistant high-performance mortar

A high-performance, mortar technology, applied in the field of building materials, can solve the problems that the bond strength and waterproofness cannot be maintained for a long time, the comprehensive performance is not outstanding, and the impact strength is low, so as to achieve strong impact resistance and extremely strong adhesion. Effects of relay force, adhesion, and low water absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

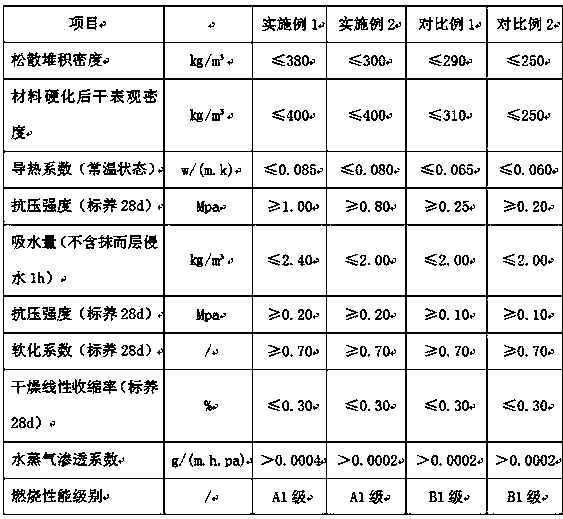

Examples

Embodiment 1

[0017] A kind of frost-resistant, crack-resistant, fire-proof and waterproof high-performance mortar, which is mainly made of the following raw materials in parts by weight: 370 parts of Portland cement, 350 parts of sulphoaluminate cement, 120 parts of 50-100 mesh river sand, silica fume ash 110 parts, 16 parts of redispersible latex powder, 7 parts of cellulose ether, 53 parts of chopped fiber, 145 parts of early strength agent, 4 parts of naphthalene superplasticizer, 0.2 part of lithium carbonate, 13 parts of calcite, 15 parts of mica, 3 parts of xonotlite, 9 parts of expanded perlite, 6 parts of wood fiber, 0.03 part of air-entraining agent, and 0.05 part of slow-release agent.

[0018] Further, vitrified microbeads are added to the mortar, and 0.15-0.20 parts of vitrified microbeads are added for every part of redispersible latex powder.

[0019] Further, the viscosity of the cellulose ether is 60,000 to 100,000.

[0020] Further, the chopped fibers are one or more of p...

Embodiment 2

[0022] A frost-resistant, crack-resistant, fireproof, and waterproof high-performance mortar is mainly made of the following raw materials in parts by weight: 370 parts of Portland cement, 370 parts of sulphoaluminate cement, 110 parts of 50-100 mesh river sand, silica fume ash 110 parts, 17 parts of redispersible latex powder, 8 parts of cellulose ether, 55 parts of chopped fiber, 130 parts of early strength agent, 4 parts of naphthalene superplasticizer, 0.2 part of lithium carbonate, 13 parts of calcite, 17 parts of mica, 3 parts of xonotlite, 9 parts of expanded perlite, 3 parts of wood fiber, 0.03 part of air-entraining agent, and 0.05 part of slow-release agent.

[0023] Further, vitrified microbeads are added to the mortar, and 0.15-0.20 parts of vitrified microbeads are added for every part of redispersible latex powder.

[0024] Further, the viscosity of the cellulose ether is 60,000 to 100,000.

[0025] Further, the chopped fibers are one or more of polypropylene ch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com