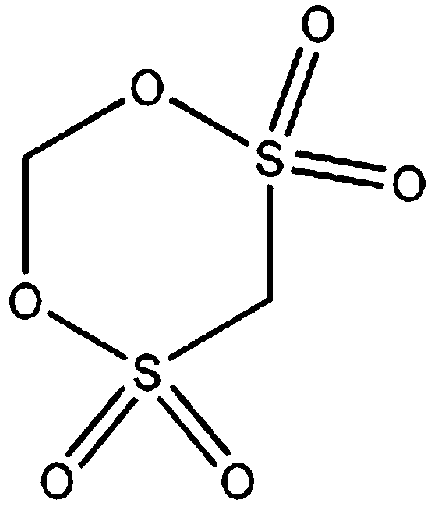

Preparation method of 1,5,2,4-dioxadithiane 2,2,4,4-tetraoxide

A technology of methylene disulfonate and methanesulfonic acid, applied in the direction of organic chemistry, can solve the problems of high energy consumption, cumbersome steps, and more three wastes, and achieve the effect of high atom utilization rate, simple production process, and less three wastes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0020] A preparation method of methylene disulfonate, the preparation method comprising sulfonation reaction and dehydration condensation reaction, the sulfonation reaction is to use methanesulfonic acid and sulfonating agent to carry out sulfonation reaction to obtain methylene disulfonic acid ; The dehydration condensation reaction is that the methylene disulfonic acid prepared by the sulfonation reaction and the formaldehyde compound are dissolved in an organic solvent, and in the presence of a dehydrating agent, the dehydration condensation reaction is carried out to generate the methylene disulfonate crude product, and the The obtained crude methylene disulfonate was added to water for washing, and dried to obtain the fine methylene disulfonate.

[0021] The sulfonating agent is one or a mixture of concentrated sulfuric acid, oleum, chlorosulfonic acid, sulfur trioxide, and sulfamic acid.

[0022] The formaldehyde compound is one or a mixture of formaldehyde gas, paraform...

Embodiment 1

[0029] At room temperature, add 48g (0.5mol) of methanesulfonic acid into a four-neck flask equipped with a stirring, thermometer, condenser, and dropping funnel, start stirring, add 40g (0.5mol) of sulfur trioxide liquid dropwise, add dropwise During the process, the internal temperature is controlled at 25°C-35°C, and the dropping time is controlled at 3-4h. After the dropwise addition, the temperature was raised to 110° C., and the temperature was kept at reflux for 6 hours. After the reaction was completed, the system was viscous liquid, which was methylene disulfonic acid by NMR analysis. The system was lowered to room temperature, 300g of sulfolane was added, stirred for 0.5h, and the system was dissolved. Take 16.5g (0.55mol) of paraformaldehyde and 35.5g (0.25mol) of phosphorus pentoxide, put them into a three-neck flask, start stirring, the system is evenly dispersed, heat up to 110°C, and keep warm for 8h. After the reaction, the system was a reddish-brown liquid. P...

Embodiment 2

[0031] At room temperature, add 48g (0.5mol) of methanesulfonic acid into a four-neck flask equipped with stirring, thermometer, condenser, and dropping funnel, start stirring, add 58g (0.5mol) of chlorosulfonic acid dropwise, the dropwise addition process The internal temperature is controlled at 25°C-35°C, and the dropping time is controlled at 3-4h. After the dropwise addition, the temperature was raised to 110°C, and the temperature was kept at reflux for 6 hours. During the reaction, hydrogen chloride was generated, and the tail gas was absorbed with lye. After the reaction, the system was a viscous liquid, which was methylene disulfonic acid by nuclear magnetic analysis. The system was lowered to room temperature, 300g of ethylene glycol dimethyl ether was added, stirred for 0.5h, and the system was dissolved. Take 16.5g (0.55mol) of paraformaldehyde and 89.1g (0.3mol) of solid phosgene into a three-necked flask, start stirring, the system is evenly dispersed, heat up t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com