Power generation system based on cylindrical linear oscillation motor and control method thereof

A technology of oscillating motor and power generation system, which is used in motor generator control, electronic commutation motor control, control system, etc., can solve the problem of high requirements on environment and installation accuracy, and achieve the effect of compact structure, reliable power and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be further described below in conjunction with the accompanying drawings.

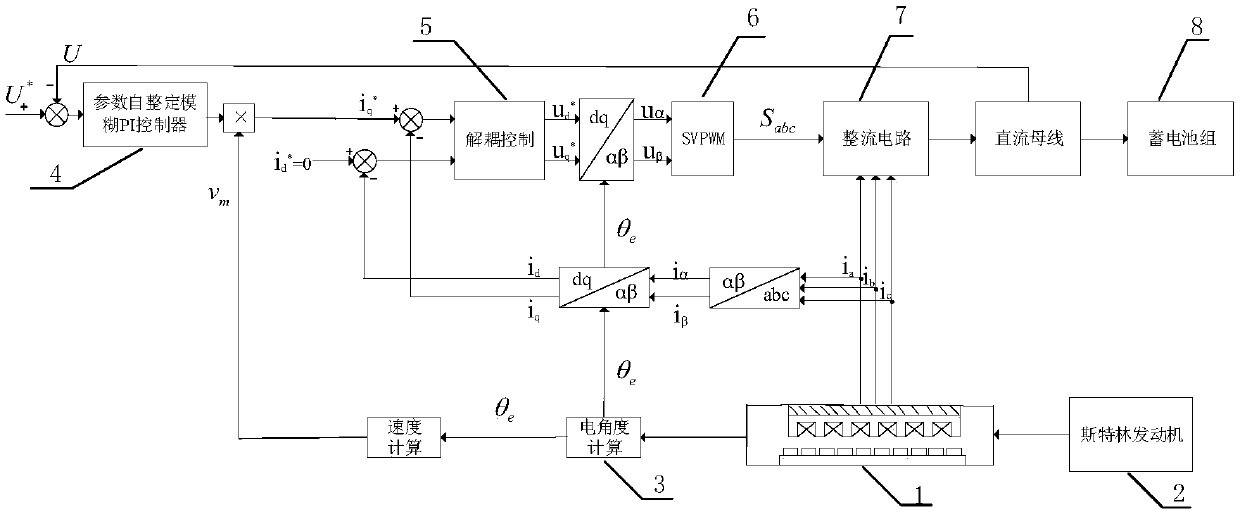

[0041] Such as figure 1 A power generation system based on a cylindrical linear oscillating motor is shown, including a free-piston Stirling engine, a cylindrical linear oscillating motor, a rectifier circuit, no position sensor, a central controller and a battery pack, wherein:

[0042] The free-piston Stirling engine consists of a displacement piston, a power piston, a heater, a regenerator, a cooler and a cylinder liner base. Through model simulation analysis and parameter optimization design, the free-piston Stirling The Lin engine achieves high energy conversion efficiency and good reciprocating oscillation amplitude stability. At the same time, through thermal optimization design, the energy transmitted from the free-piston Stirling engine to the cylinder linear oscillating motor can be efficiently and stably;

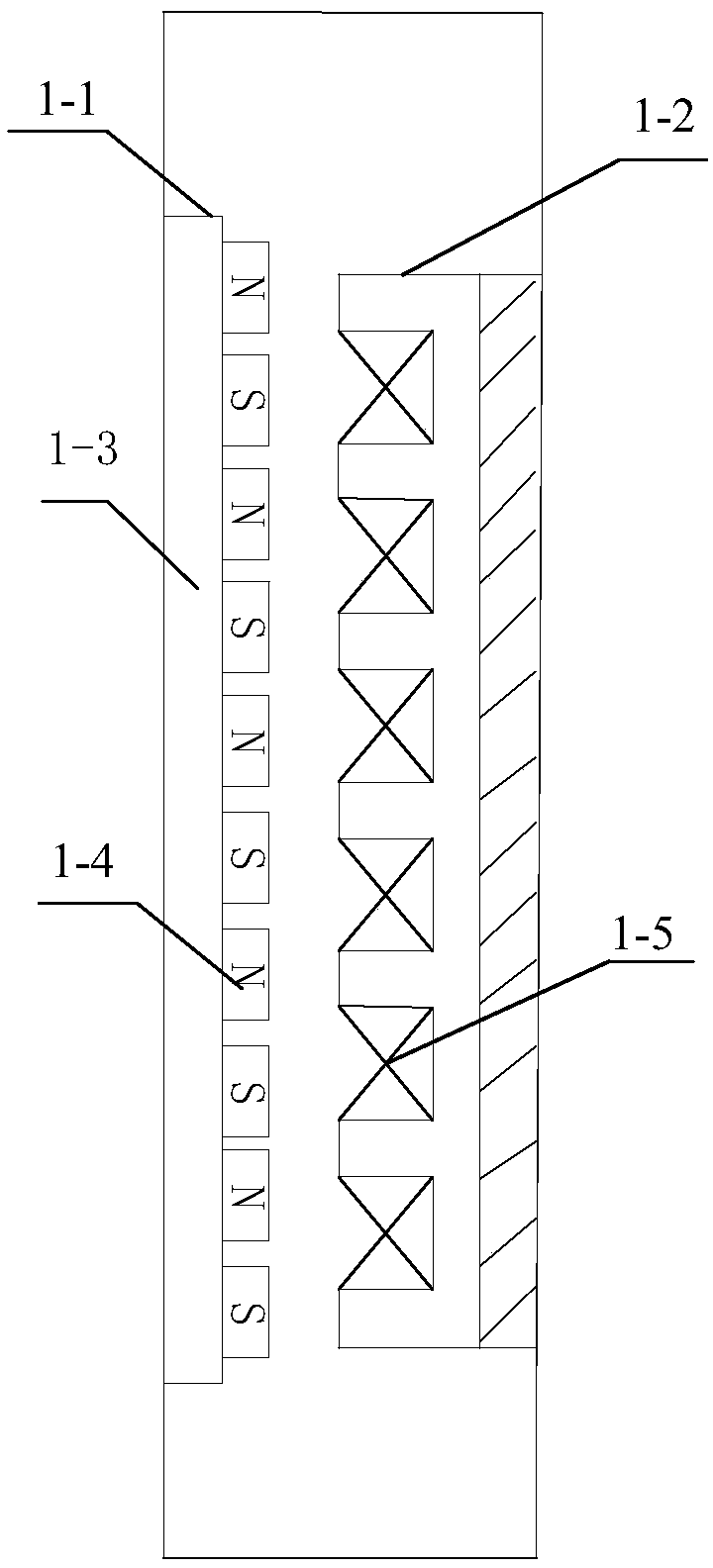

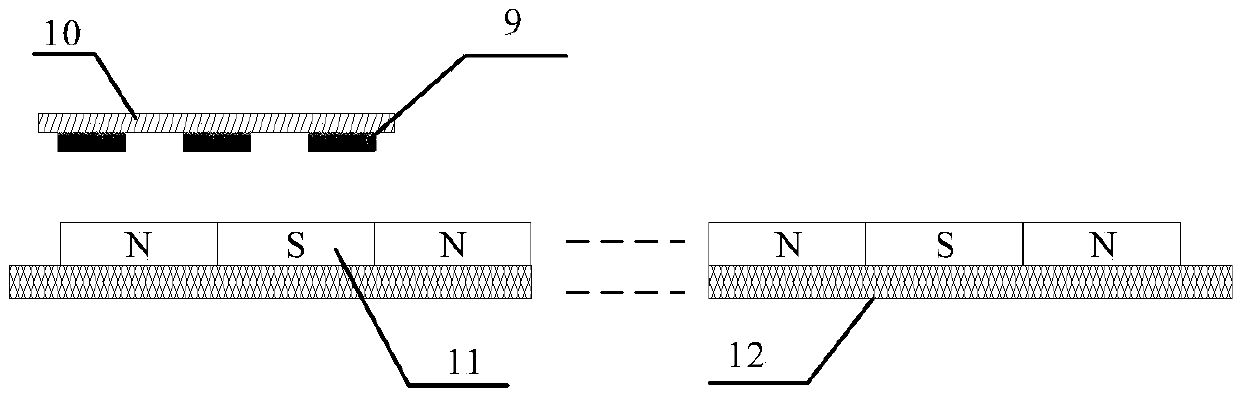

[0043] Cylindrical linear oscillating motor, incl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com