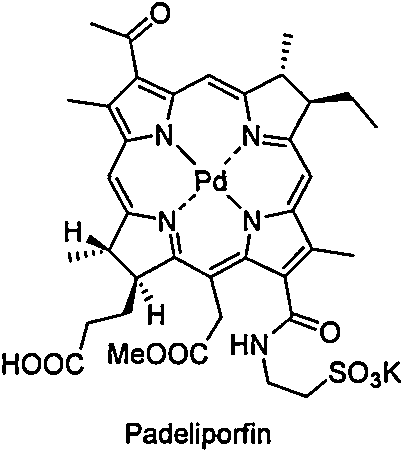

Diphenyltetrahydroporphin compound, preparation method and application thereof

A technology of diphenyltetrahydroporine and compound, applied in the field of diphenyltetrahydroporine compound and preparation thereof, can solve the problems of complex composition, weak absorption, difficult preparation and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

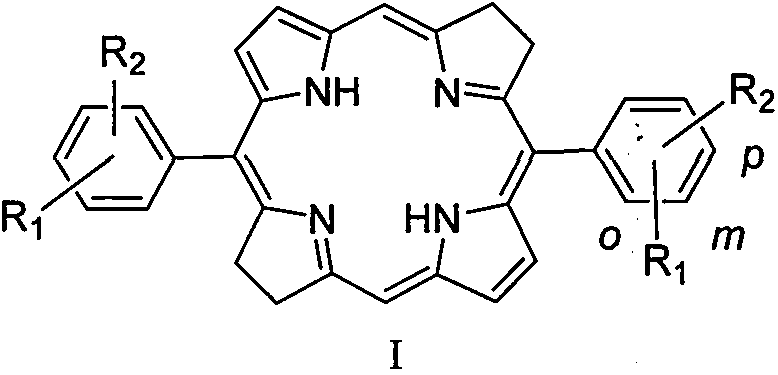

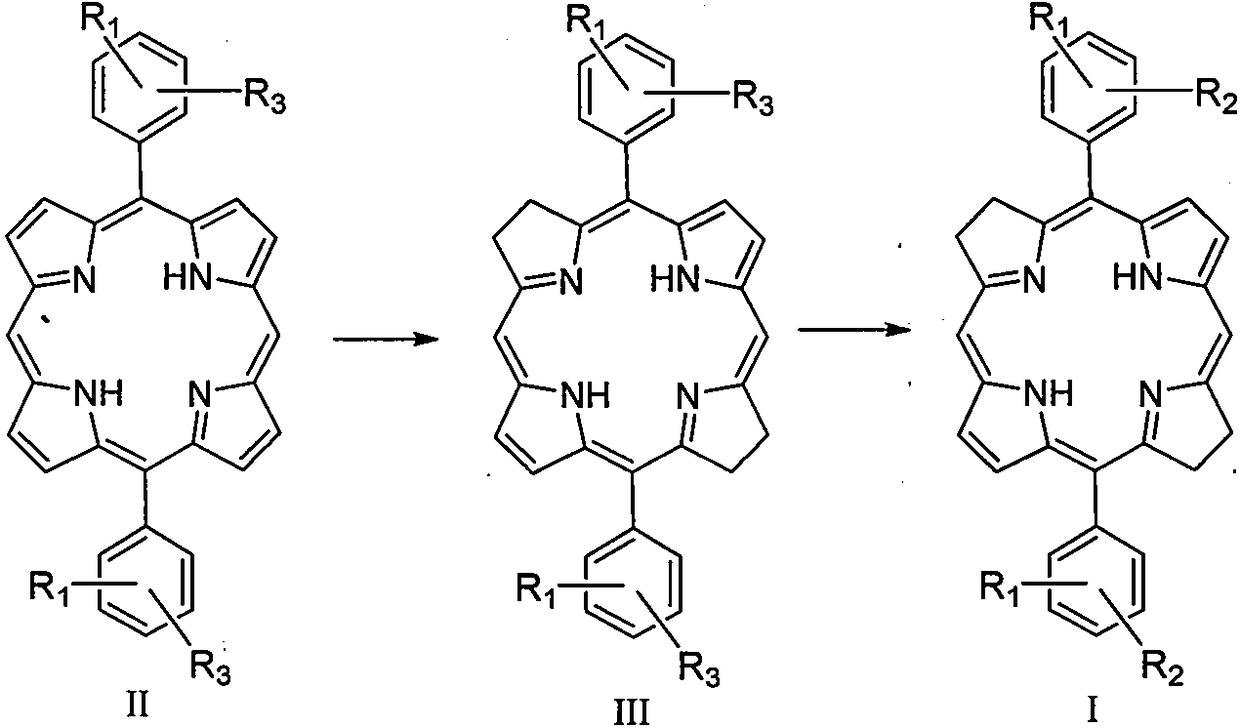

[0028] 5,15-two [(3-carboxymethoxy) phenyl] tetrahydroporphine (1) synthetic preparation method

[0029]

[0030] Compound 2 (333mg, 0.5mmol) and potassium carbonate (828mg, 6mmol) were added to pyridine (23mL), stirred, and heated to reflux under nitrogen protection; a pyridine solution of p-toluenesulfonyl hydrazide (0.5mol / L) was added dropwise , Thin-layer chromatography (TLC) monitored until the reaction was complete. After the reaction solution was cooled, ethyl acetate (100 mL) and distilled water (50 mL) were added, and heated to reflux for 1 h. Cool, neutralize with hydrochloric acid solution (2mol / L), and let stand to separate layers. The organic phase was washed with saturated brine (50 mL×3), dried over anhydrous sodium sulfate, filtered with suction, and the filtrate was evaporated under reduced pressure to remove the solvent. The obtained residue was separated and purified by column chromatography to obtain diphenyltetrahydroporphine compound 3 (95.2 mg, 28....

Embodiment 2

[0033] The preparation method of 5,15-bis[(3-carboxypropoxy)phenyl]tetrahydroporphine (4)

[0034]

[0035] Compound 5 (361mg, 0.5mmol) and potassium carbonate (828mg, 6mmol) were added to pyridine (23mL), stirred, and heated to reflux under nitrogen protection; a pyridine solution of p-toluenesulfonylhydrazide (0.5mol / L) was added dropwise , TLC monitors the complete reaction of raw materials. The reaction solution was cooled, ethyl acetate (100 mL) and distilled water (50 mL) were added and heated to reflux for 1 h. Cool, neutralize with hydrochloric acid solution (2mol / L), and let stand to separate layers. The organic phase was washed with saturated brine (50 mL×3), dried over anhydrous sodium sulfate, filtered with suction, and the filtrate was evaporated under reduced pressure to remove the solvent. The resulting residue was separated and purified by column chromatography to obtain diphenyltetrahydroporphin compound 6 (125.3 mg, 34.5%).

[0036] Compound 6 (363 mg, ...

Embodiment 3

[0038] The preparation method of 5,15-bis[(3-carboxymethoxy-4-methoxy)phenyl]tetrahydroporphine (7)

[0039]

[0040] Compound 8 (363mg, 0.5mmol) and potassium carbonate (828mg, 6mmol) were added to pyridine (23mL), stirred, and heated to reflux under nitrogen protection; a pyridine solution of p-toluenesulfonyl hydrazide (0.5mol / L) was added dropwise , TLC monitors the complete reaction of raw materials. The reaction solution was cooled, ethyl acetate (100 mL) and distilled water (50 mL) were added, and heated to reflux for 1 h. Cool, neutralize with HCl solution (2mol / L), and let stand to separate the layers. The organic phase was washed with saturated brine (50 mL×3), dried over anhydrous sodium sulfate, filtered with suction, and the filtrate was evaporated under reduced pressure to remove the solvent. The resulting residue was separated and purified by column chromatography to obtain diphenyltetrahydroporphin compound 9 (96.8 mg, 26.5%).

[0041] Compound 9 (365 mg,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com