A coal-based mixed high energy density fuel and its preparation method

A high-energy-density, coal-based technology, applied in the field of coal chemical industry, can solve the problems of not realizing the maximum utilization of the full fraction of coal-based derived oil, low yield of high-energy-density fuel products, low density and energy density, etc. A wide range of applications, the effect of improving mobility and penetration capability, large mass density and volumetric calorific value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

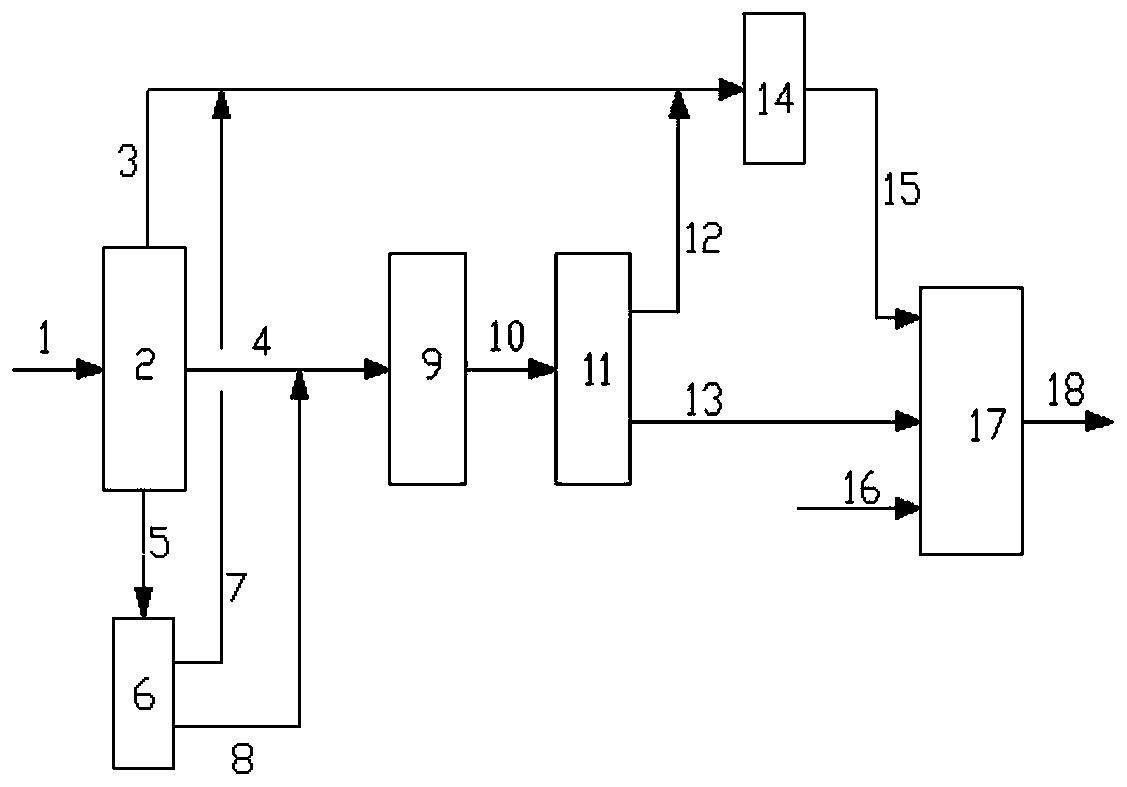

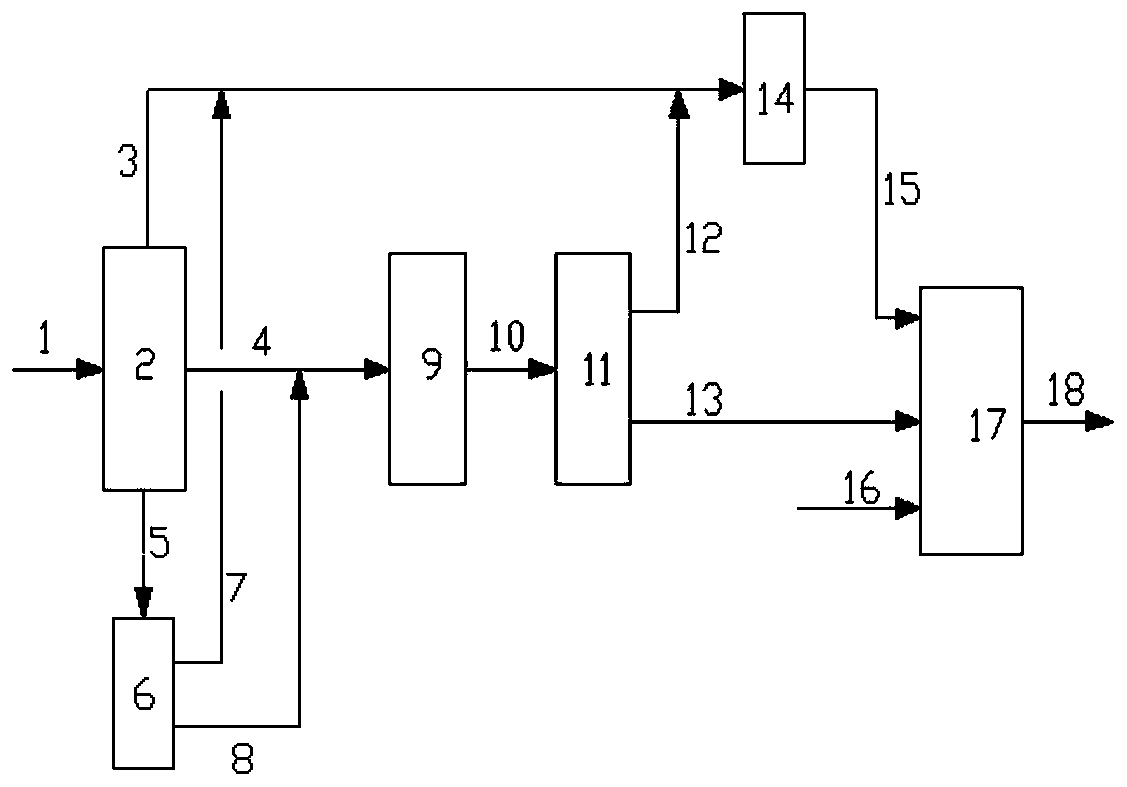

[0044] Such as figure 1 Shown, the preparation method of a kind of coal-based mixed high energy density fuel that one embodiment of the present invention proposes, it comprises:

[0045] Distillation separation: the coal-based derived oil 1 enters the distillation separation unit 2 and undergoes distillation separation to obtain the first naphtha fraction 3, diesel fraction 4 and heavy oil fraction 5;

[0046] Hydrocracking: The heavy oil fraction 5 and hydrogen are mixed and sent to the hydrocracking unit 6 through a high-pressure pump, and hydrogen-rich gas and liquid phase oil are obtained through oil slurry preparation, hydrocracking reaction, and gas-liquid separation; hydrogen-rich The gas is used as circulating hydrogen; the liquid phase oil is distilled to obtain cracked naphtha fraction 7 and cracked diesel fraction 8;

[0047] Hydrogenation and upgrading: the diesel oil fraction 4 and the cracked diesel oil fraction 8 are mixed and then mixed with hydrogen to enter ...

Embodiment 1

[0077] One embodiment of the present invention proposes a method for preparing a coal-based mixed high-energy-density fuel, which includes:

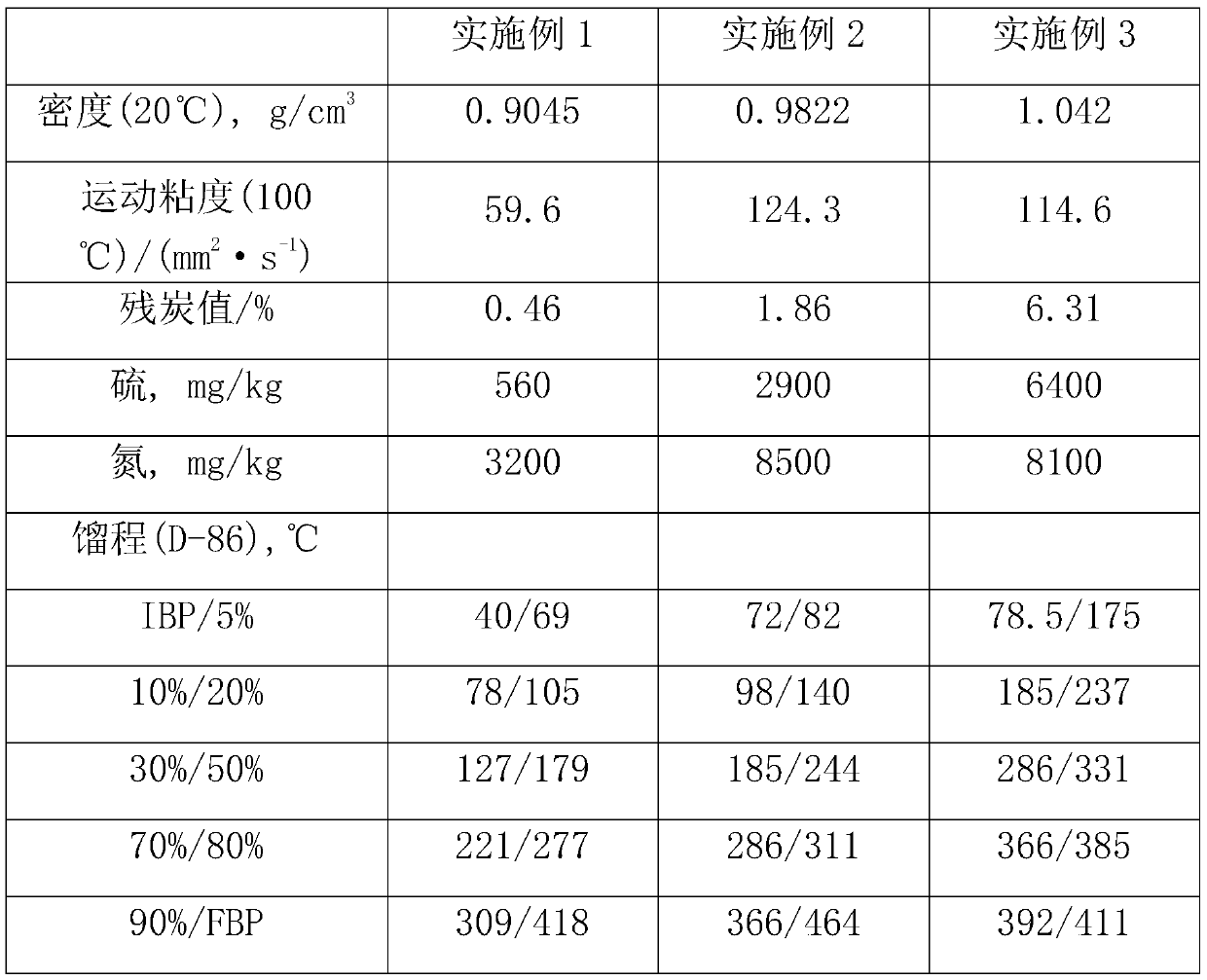

[0078] Distillation and separation: using black mountain bituminous coal direct liquefaction oil as raw material oil, through distillation separation, the first naphtha fraction at 350°C are obtained; the properties of the raw oil are shown in Table 1 shown;

[0079] Hydrocracking: prepare heavy oil fractions through oil slurry preparation, hydrocracking reaction, and gas-liquid separation to obtain hydrogen-rich gas and liquid phase oils; distill the liquid phase oils to obtain cracked naphtha fractions and Cracked diesel fraction; the scale of the hydrocracking unit is 0.01t / d, and the hydrocracking unit adopts two suspended bed reactors connected in series;

[0080] Hydrogenation and upgrading: hydrogenation and upgrading of diesel fraction and cracked diesel fraction to obtain hydrogenation and upgrading oil; the hydrogenation and u...

Embodiment 2

[0086] One embodiment of the present invention proposes a method for preparing a coal-based mixed high-energy-density fuel, which includes:

[0087] Distillation and separation: The kerosene co-refined oil obtained by the co-hydrogenation of lignite and catalytic cracking oil slurry is used as the raw material oil, through distillation and separation, the first naphtha fraction of 370°C are obtained. Quality oil fraction; The properties of raw material oil are as shown in table 1;

[0088] Hydrocracking: prepare heavy oil fractions through oil slurry preparation, hydrocracking reaction, and gas-liquid separation to obtain hydrogen-rich gas and liquid phase oils; distill the liquid phase oils to obtain cracked naphtha fractions and Cracked diesel fraction; the scale of the hydrocracking unit is 0.01t / d, and the hydrocracking unit adopts two suspended bed reactors connected in series;

[0089] Hydrogenation and upgrading: Hydrogenation and upgrading of diesel fraction and crack...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com