X-ray broadband energy selection device and method for manufacturing same

A production method and energy selection technology, applied in the field of X-ray optics, can solve the problems that the unit size cannot reach the nanometer level, the number of reflections, the reflection ratios are different, and the bandpass imaging cannot be realized, and the bandpass energy range can be selected arbitrarily. , High yield and small size of micro-elements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

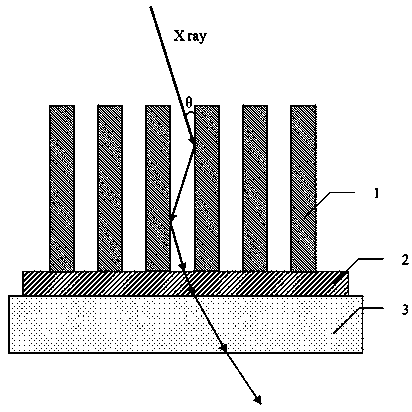

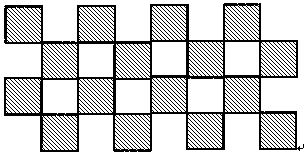

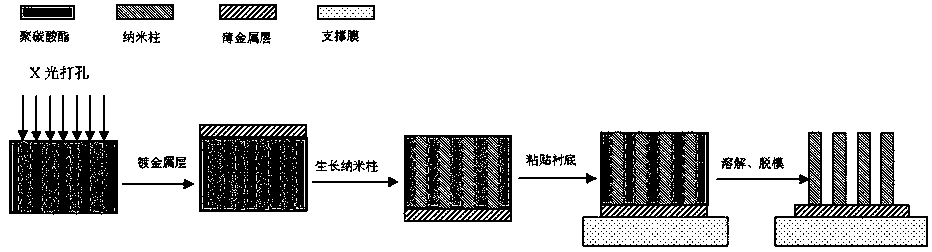

[0041] In this embodiment, the X-ray with a wavelength of less than 0.1nm on the synchrotron radiation device is used for X-ray lithography. The holes are square, the side length is 200nm, and the depth of the holes is 8um. The arrangement of the holes is as follows image 3 shown. Metal Ag with a thickness of 200 nm was plated on the surface of the perforated polycarbonate by magnetron sputtering. Then Au nanocolumns are grown in the holes on the front side of the thin metal layer 2 by electrochemical deposition until the holes are filled. On the back side of the thin metal layer 2, a polyimide support film 3 with a thickness of 2 um is pasted. Finally, the polycarbonate is dissolved by the organic solvent dichloromethane to form a nano-column array with a polyimide support film 3 .

[0042] When X-rays with a complex spectrum are irradiated on the nano-column array 1 at a grazing incidence angle of 2°, the X-rays are reflected and absorbed by the top and side walls of the ...

Embodiment 2

[0044] The embodiment of this embodiment is basically the same as that of Embodiment 1, the main difference being that the thin metal layer plated on the surface of the perforated polycarbonate by magnetron sputtering is metal Al with a thickness of 2 um. When X-rays with a complex spectrum are irradiated on the nano-column array 1 at a grazing incidence angle of 2°, the X-rays are reflected and absorbed by the top and side walls of the Au nano-columns, the thin metal layer 2 and the support film 3, and the X-ray broadband energy selection The transmittance curve of the device is as Figure 5 As shown, its gating energy band ranges from 800eV to 1600eV.

Embodiment 3

[0046] This embodiment is basically the same as that of Embodiment 1, the main difference being that the grazing incidence angle is 3.4°. When X-rays with a complex spectrum are irradiated on the nano-column array 1 at a grazing incidence angle of 3.4°, the X-rays are reflected and absorbed by the top and side walls of the Au nano-columns, the thin metal layer 2 and the support film 3, and the X-ray broadband energy selection The transmittance curve of the device is as Image 6 As shown, its gating energy band ranges from 400eV to 1400eV, including the N-band energy segment of Au. The device is placed in front of the photocathode of the framing camera, and can be used for N-band spectrum radiation framing imaging diagnosis in the gold black cavity radiation spectrum.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com