Gallium nitride-based high electron mobility transistor

A high electron mobility, gallium nitride-based technology, applied in the field of gallium nitride-based high electron mobility transistors, can solve the problem of increased device on-resistance, reduced device buffer layer leakage current, and limited increase in device breakdown voltage, etc. problem, to achieve the effect of ensuring the operating frequency and switching speed, optimizing the distribution of the transverse electric field, and ensuring the forward current capability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

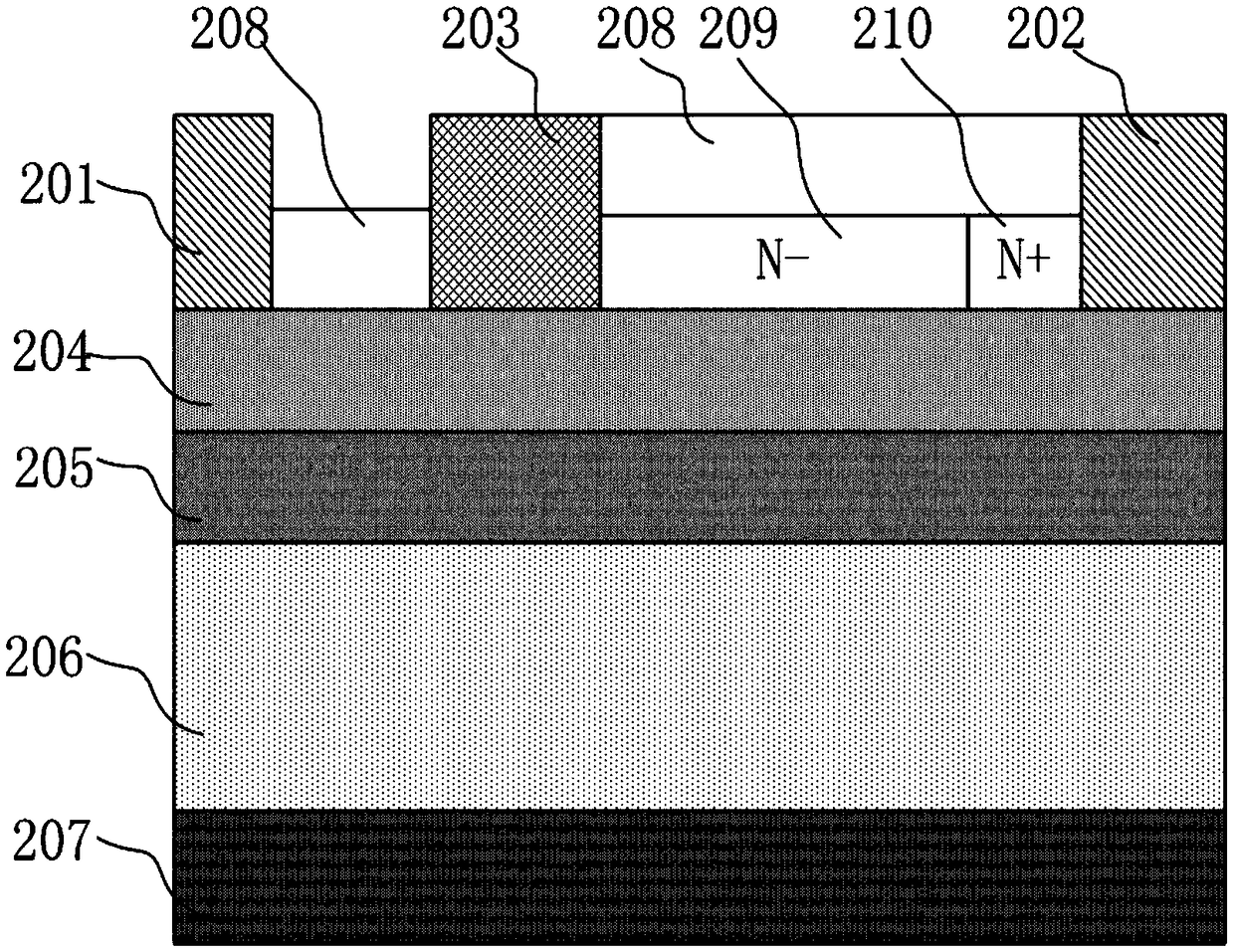

[0032] This embodiment provides a GaN-based high electron mobility transistor, such as figure 2 As shown, it includes a substrate 207, a gallium nitride buffer layer 206, a gallium nitride channel layer 205, an aluminum gallium nitride barrier layer 204, and a substrate 207 disposed on the aluminum gallium nitride barrier layer 204, which are sequentially stacked from bottom to top. The source electrode 201, the drain electrode 202 and the gate electrode 203 on the surface; the molecular formula of the aluminum gallium nitrogen barrier layer 204 in this embodiment is Al x Ga y N, where 0≤x≤1, 0≤y≤1, x+y=1; both the source 201 and the drain 202 form ohmic contacts with the AlGaN barrier layer 204, and the gate The electrode 203 forms a Schottky contact with the AlGaN barrier layer 204; it is characterized in that: the upper surface of the AlGaN barrier layer 204 between the gate 203 and the drain 202 is provided with N-type semiconductors in contact with each other layer 209...

Embodiment 2

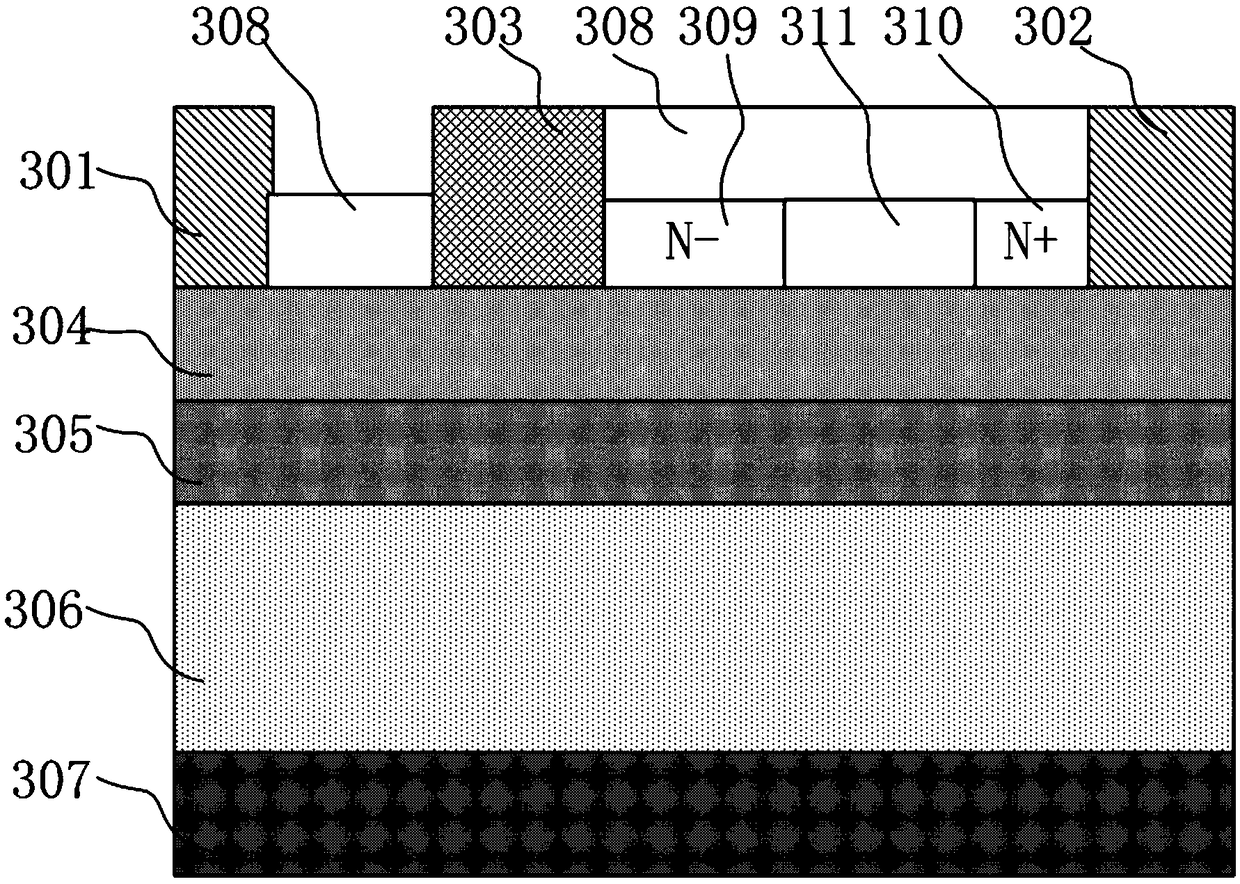

[0034] This embodiment provides a GaN-based high electron mobility transistor, such as image 3 As shown, it includes a substrate 307, a gallium nitride buffer layer 306, a gallium nitride channel layer 305, an aluminum gallium nitride barrier layer 304, and an aluminum gallium nitride barrier layer 304 that are stacked sequentially from bottom to top. The source electrode 301, the drain electrode 302 and the gate electrode 303 on the surface; the molecular formula of the aluminum gallium nitrogen barrier layer 204 in this embodiment is Al x Ga y N, where 0≤x≤1, 0≤y≤1, x+y=1; both the source 301 and the drain 302 form an ohmic contact with the AlGaN barrier layer 304, and the gate The electrode 303 forms a Schottky contact with the AlGaN barrier layer 304; it is characterized in that: the upper surface of the AlGaN barrier layer 304 between the gate 303 and the drain 302 is provided with N - IN + structure, the N - IN + The structure includes an N-type semiconductor layer...

Embodiment 3

[0036] This embodiment adopts as figure 2 The shown device structure is subjected to a two-dimensional numerical simulation test. In order to compare the performance of the present invention with a traditional GaN HEMT device, this embodiment adopts a traditional method with the same parameters except that the N-type semiconductor layer 209 and the N+ type semiconductor layer 210 are not introduced. A GaN HEMT device was used as a comparative example. The structural parameters used for device simulation are shown in Table 1 below:

[0037] Table 1 Device Simulation Structure Parameters

[0038]

[0039]

[0040] Such as Figure 4 and Figure 5 As shown, the simulation results of this embodiment fully demonstrate the advantages of the present invention. from Figure 4 It can be seen that the specific embodiment of the present invention proposes that the breakdown voltage value of the GaN HEMT device is 1354V, while the breakdown voltage value of the common GaN HEMT ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com