Pungent grilled sausage processing technique

A processing technology, technology of grilling sausages, applied in the direction of food ingredients as taste improvers, food ingredients as taste improvers, functions of food ingredients, etc., can solve the problem of not endowing nutritional value and health value, threatening human health, high fat, etc. problem, to achieve the effect of scientific and reasonable preparation method, good economic benefit and market promotion value, and low fat content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

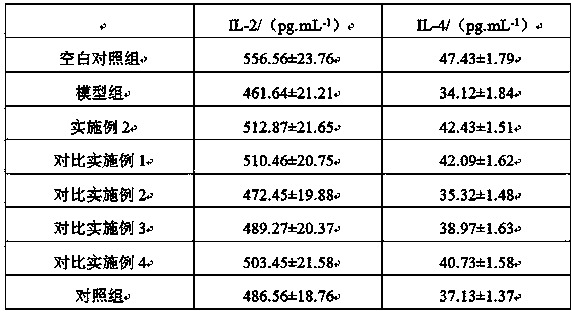

Examples

Embodiment 1

[0026] A processing technology for spicy grilled sausages, comprising the following steps:

[0027] (1) Pretreatment of pork belly: wash the fresh pork belly under tap water, then put it in a meat grinder and grind it, then soak the minced meat in ginger soup for 2 hours and take it out for later use;

[0028] (2) Preparation of brine:

[0029] a. Weigh 10 parts of pepper, 9 parts of Chinese prickly ash, 16 parts of edible salt, 13 parts of white sugar, 1 part of monosodium glutamate, and 20 parts of modified traditional Chinese medicine in corresponding weight parts and place them in a micro-jet homogenizer for processing, and take them out after 20 minutes of processing Mixture A is standby;

[0030] b. Add the mixture A obtained in operation a and white wine into the stirring tank according to the weight ratio of 1:2.6, and stir while heating. The temperature in the stirring tank is controlled at 78°C. After stirring for 45 minutes, take it out to obtain the mixture B;

...

Embodiment 2

[0043] A processing technology for spicy grilled sausages, comprising the following steps:

[0044] (1) Pretreatment of pork belly: wash the fresh pork belly under tap water, then put it in a meat grinder and grind it, then soak the minced meat in ginger soup for 2.5 hours and take it out for later use;

[0045] (2) Preparation of brine:

[0046] a. Weigh 12 parts of pepper, 10 parts of Chinese prickly ash, 17 parts of edible salt, 15 parts of sugar, 2 parts of monosodium glutamate, and 24 parts of modified traditional Chinese medicine in corresponding weight parts and place them in a micro-jet homogenizer for processing, and take them out after 25 minutes of processing Mixture A is standby;

[0047] b. Add the mixture A obtained in operation a and white wine into the stirring tank according to the weight ratio of 1:2.9, and stir while heating. The temperature in the stirring tank is controlled at 83°C. After stirring for 55 minutes, take it out to obtain the mixture B;

[0...

Embodiment 3

[0060] A processing technology for spicy grilled sausages, comprising the following steps:

[0061] (1) Pretreatment of pork belly: wash the fresh pork belly under tap water, then put it in a meat grinder and grind it, then soak the minced meat in ginger soup for 3 hours and take it out for later use;

[0062] (2) Preparation of brine:

[0063] a. Weigh 14 parts of pepper, 11 parts of Chinese prickly ash, 18 parts of edible salt, 17 parts of white sugar, 3 parts of monosodium glutamate, and 28 parts of modified traditional Chinese medicine in corresponding weight parts and place them in a micro-fluid homogenizer for processing, and take them out after 30 minutes of processing Mixture A is standby;

[0064] b. Add the mixture A and liquor obtained in operation a into the stirring tank according to the weight ratio of 1: 3.2, and stir while heating. The temperature in the stirring tank is controlled at 88°C. After stirring for 65 minutes, take it out to obtain the mixture B;

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com