Polymer microporous membrane as well as preparation method and application thereof

A polymer and microporous membrane technology, applied in chemical instruments and methods, membranes, membrane technology, etc., to achieve the effects of broadening applicability, improving water drawing efficiency, and reducing heat conduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

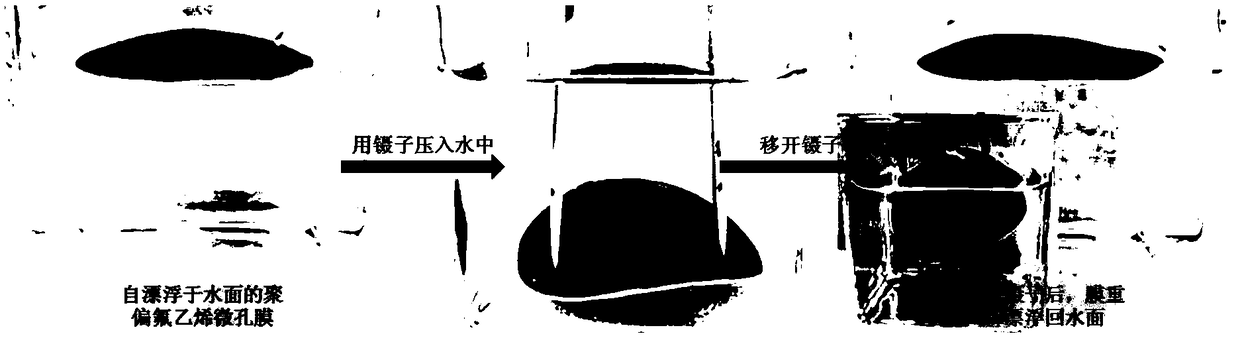

[0035]The present invention also provides a method for preparing a polymer microporous membrane for light-to-heat conversion, using non-woven fabric as a template, comprising the following steps:

[0036] S1, dissolving the polymer in an organic solvent to obtain a polymer casting solution;

[0037] S2, coating the casting solution obtained in step (1) on the surface of the non-woven fabric to form a nascent film;

[0038] S3, transfer the non-woven fabric with the nascent film to a coagulation bath and solidify at 10°C to 30°C to obtain a polymer microporous film with a non-woven fabric, wherein the coagulation bath is an aqueous solution of sodium chloride or aqueous ammonia and hydrophilic Water-based polymer and the mixture with step (1) organic solvent, during the solidification process, sodium chloride or ammonia water induces the phase transition of polymer precipitation, driving the polymer in the casting solution to stay away from the surface of the non-woven fabric i...

Embodiment 1

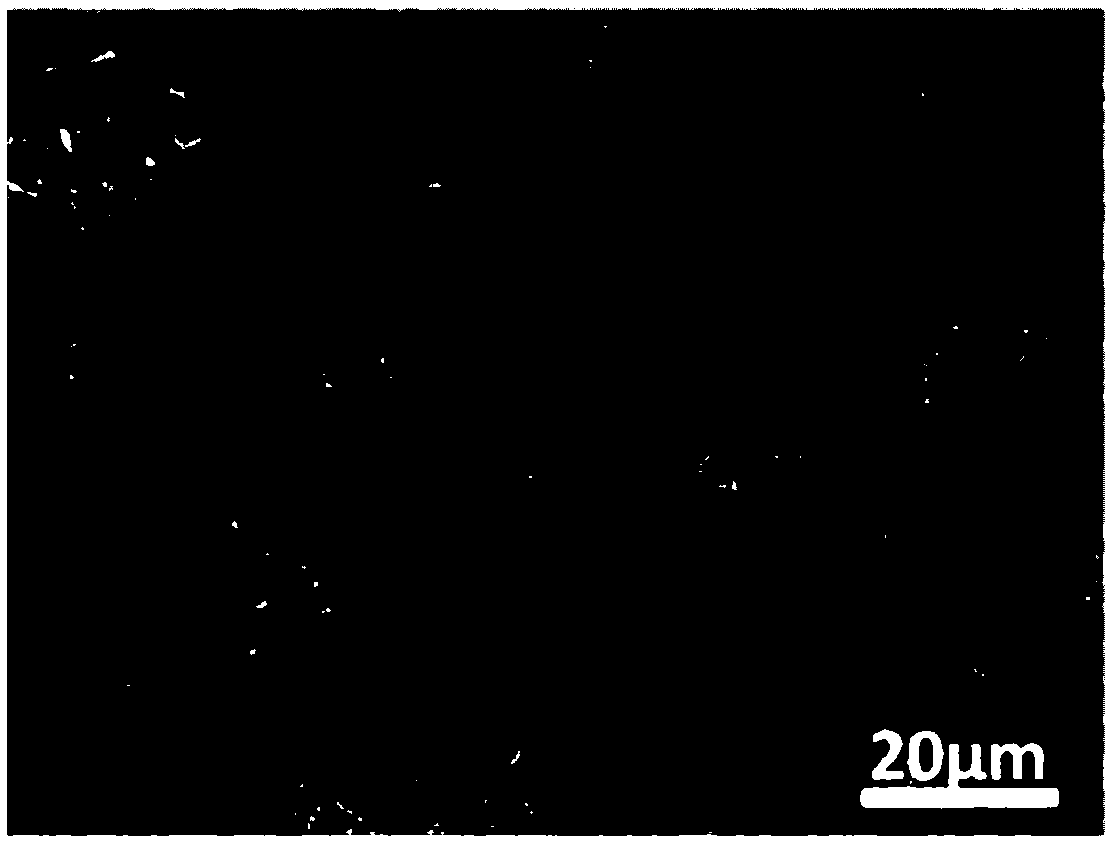

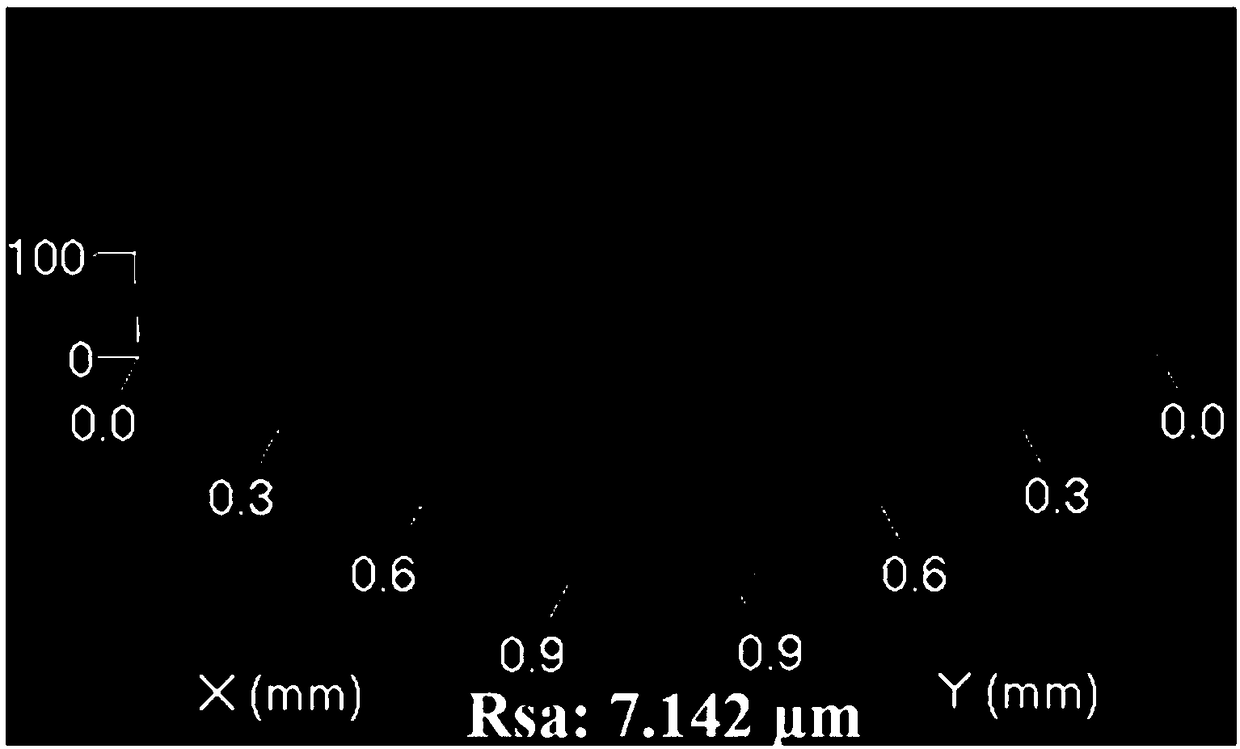

[0052] Step (1) Add 16g of polyvinylidene fluoride and 84g of triethyl phosphate to the reaction kettle, and mechanically stir at 250r / min at 70°C for 6 hours, then vacuum defoaming for 20 minutes, and then stand for defoaming for 10 hours to obtain Polyvinylidene fluoride casting liquid;

[0053] Step (2) uniformly coating the polyvinylidene fluoride casting solution on the support layer made of non-woven fabric with a 250-micron scraper to obtain a nascent film;

[0054] Step (3) Transfer the nascent membrane into a coagulation bath at 25°C and immerse it for 5 minutes, then transfer it to deionized water at 60°C and place it for 24 hours to obtain a polyvinylidene fluoride microporous membrane with a non-woven support layer, The coagulation bath is to add 2g N-vinylpyrrolidone, 1.5g vinyltrimethoxysilane and 0.1g azobisisobutyronitrile to 50mL triethyl phosphate, react at 60°C for 16 hours, and then mix with 50mL mass fraction Prepared by blending 6% sodium chloride aqueou...

Embodiment 2

[0067] Step (1) Add 13g of polyvinylidene fluoride, 5g of polyethylene glycol, and 82g of N,N-dimethylformamide into the reactor, and mechanically stir at 200r / min at 80°C for 5 hours, and then vacuum defoam for 30 Minutes, then stand for degassing for 15 hours to obtain polyvinylidene fluoride casting solution;

[0068] Step (2) uniformly coating the polyvinylidene fluoride casting solution on the non-woven fabric support layer with a 300-micron scraper to obtain a nascent film;

[0069] Step (3) Transfer the nascent film into a reactive coagulation bath at 20°C for 8 minutes, then transfer it to deionized water at 55°C and place it for 30 hours to obtain a microporous polyvinylidene fluoride with a non-woven support layer film, wherein the reactive coagulation bath is 1g N-vinylpyrrolidone, 1.5g hydroxyethyl methacrylate, 2g vinyltriethoxysilane and 0.14g dioxane in 50mL N,N-dimethylformamide Azodiisoheptanonitrile was prepared by blending with 80mL ammonia solution with a ma...

PUM

| Property | Measurement | Unit |

|---|---|---|

| contact angle | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com