SCR (silicon controlled rectifier) catalyst slurry and preparation method and application thereof

A technology of SCR catalyst and slurry, which is applied in the direction of catalyst activation/preparation, chemical instruments and methods, physical/chemical process catalysts, etc., and can solve the problems of reduced production efficiency and excessive air-drying speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

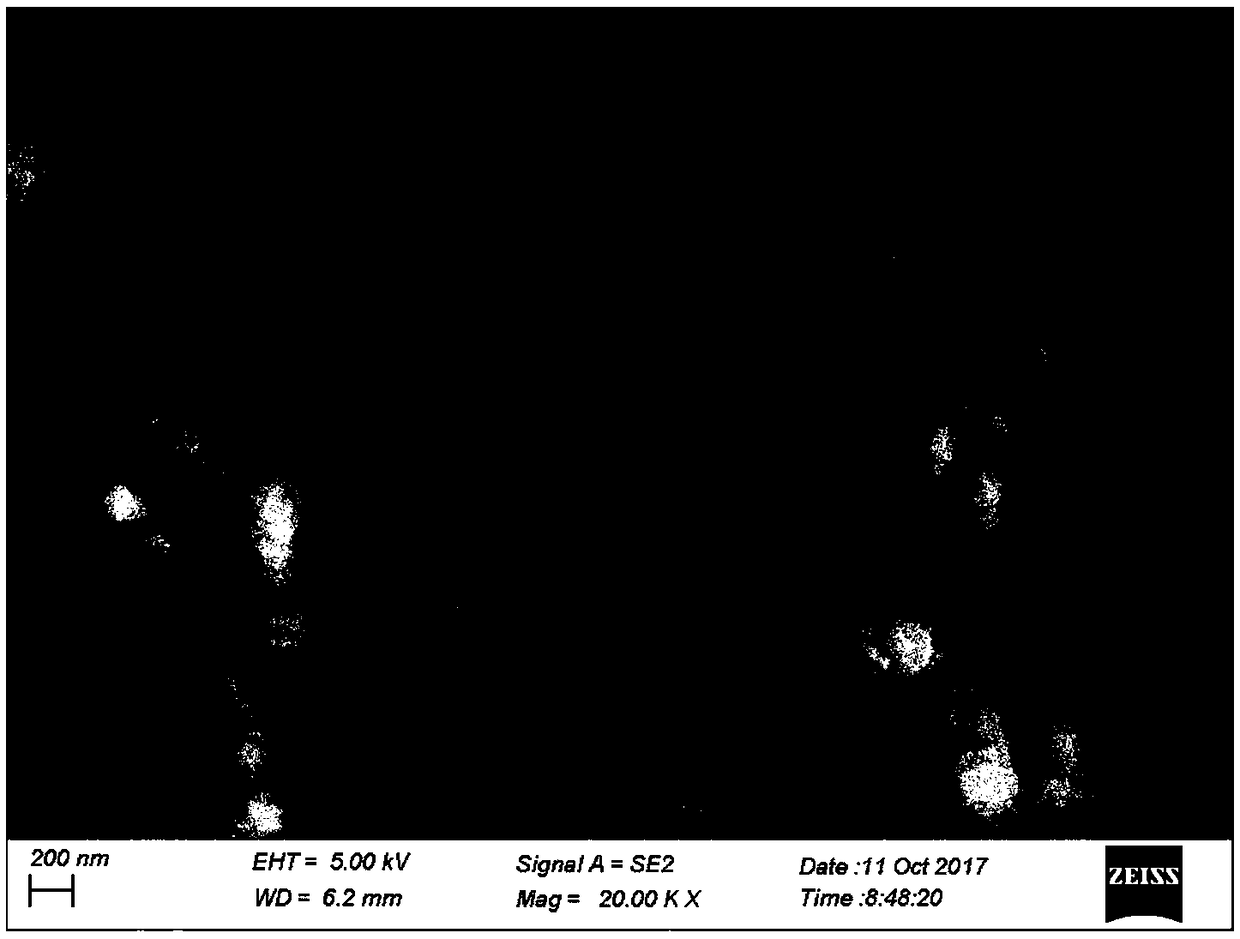

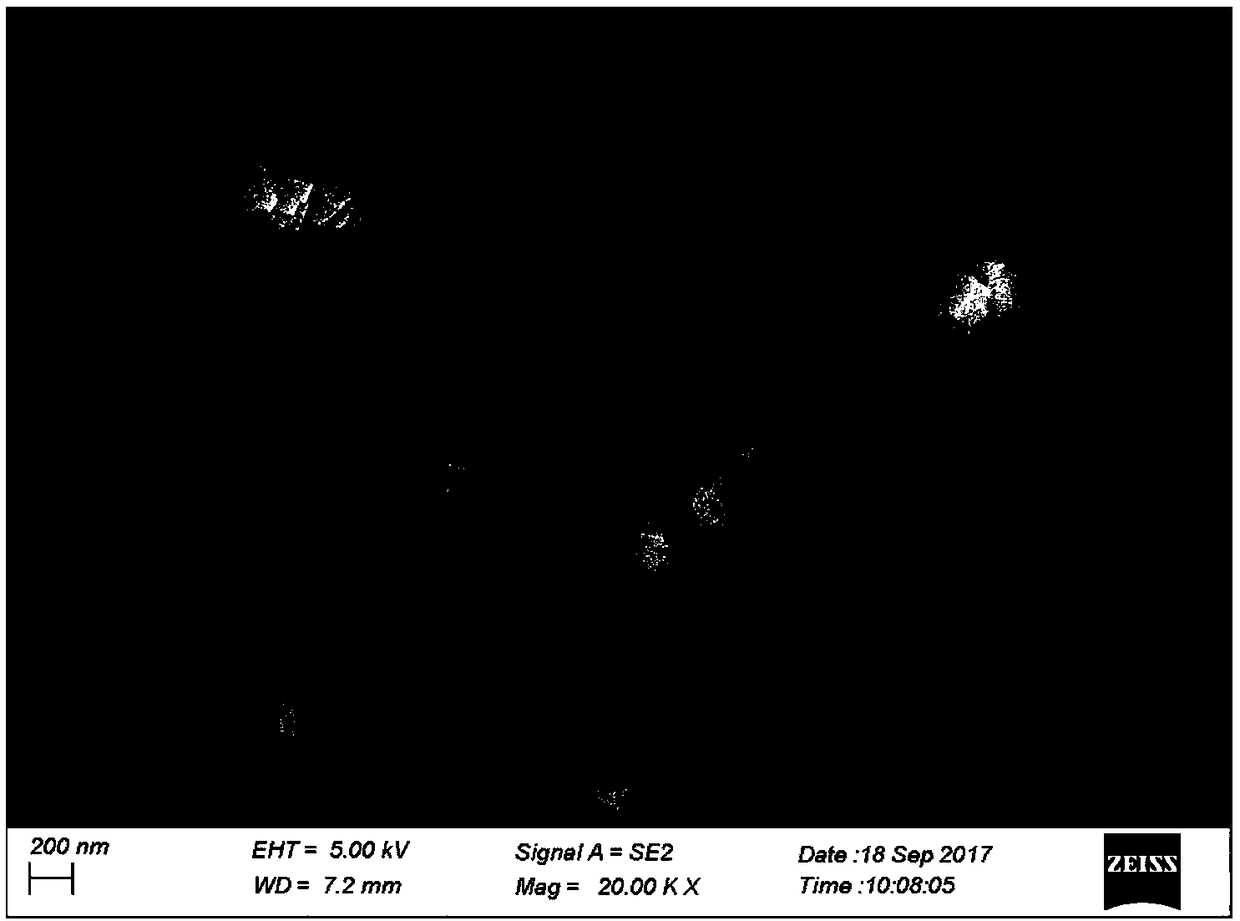

Image

Examples

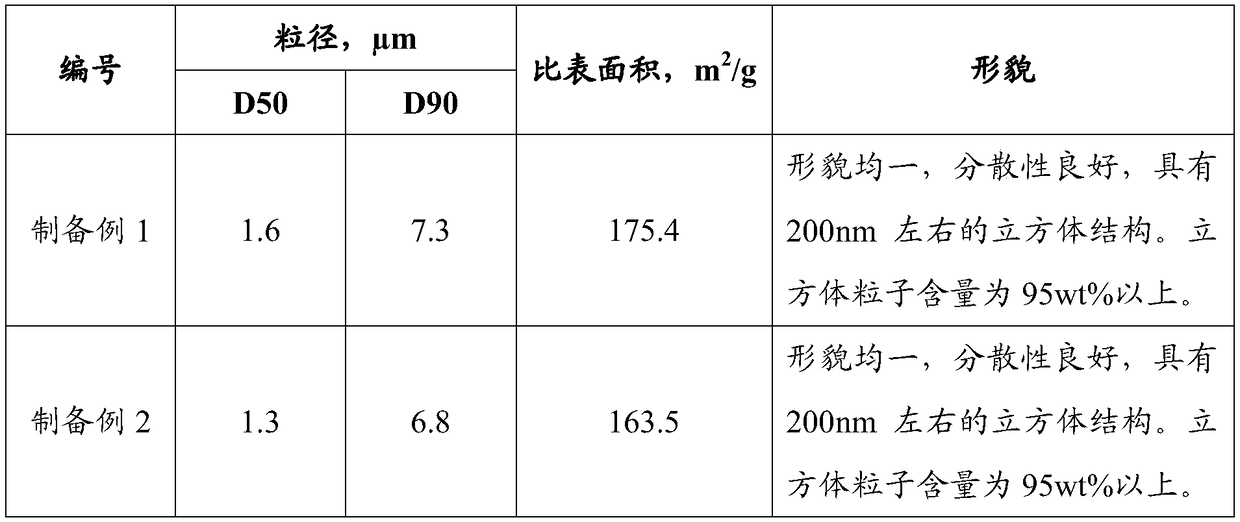

preparation example Construction

[0062]

[0063] The raw materials containing SCR catalyst, cellulose ether, pore forming agent, aluminum sol, silica sol, defoamer and water are mixed to obtain the SCR catalyst slurry. The preparation method of SCR catalyst slurry of the present invention comprises following specific steps:

[0064] (1) Aluminum sol, silica sol, defoamer and water are mixed uniformly to form a mixed solution;

[0065] (2) Mix the SCR catalyst, cellulose ether and pore-forming agent evenly, then add them into the mixed solution under continuous stirring, and continue stirring for 1-4 hours after the addition, to obtain the SCR catalyst slurry.

[0066] In some embodiments, aluminum sol, silica sol, defoamer and water are mixed uniformly to obtain a mixed solution; SCR catalyst, ammonium bicarbonate and cellulose ether are mixed uniformly, and then added to the In the mixed solution, after the addition is completed, the stirring is continued for 1-3 hours, preferably 1.5-2.5 hours, to obtain...

preparation example 1

[0085] The preparation of preparation example 1-cerium glutamate

[0086] Add 1.335 g of glutamic acid to 25 mL of H 2 O, heated to 65°C, stirred evenly, then added 2.67g of cerium carbonate and stirred for 2h.

preparation example 2

[0087] The preparation of preparation example 2-cerium gluconate

[0088] Add 1.98 g of glucose and 2.67 g of cerium carbonate to 25 mL of H 2 O, heated to 60 ° C, stirred for 1 h.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com