Preparation method of black glaze heat-resistant ceramic pot

A technology of black glaze and ceramic pots, which is applied in the preparation of black glaze heat-resistant ceramic pots and in the field of black glaze heat-resistant ceramic pots. Vibrant color, increased gloss, and reduced air bubbles and pinholes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

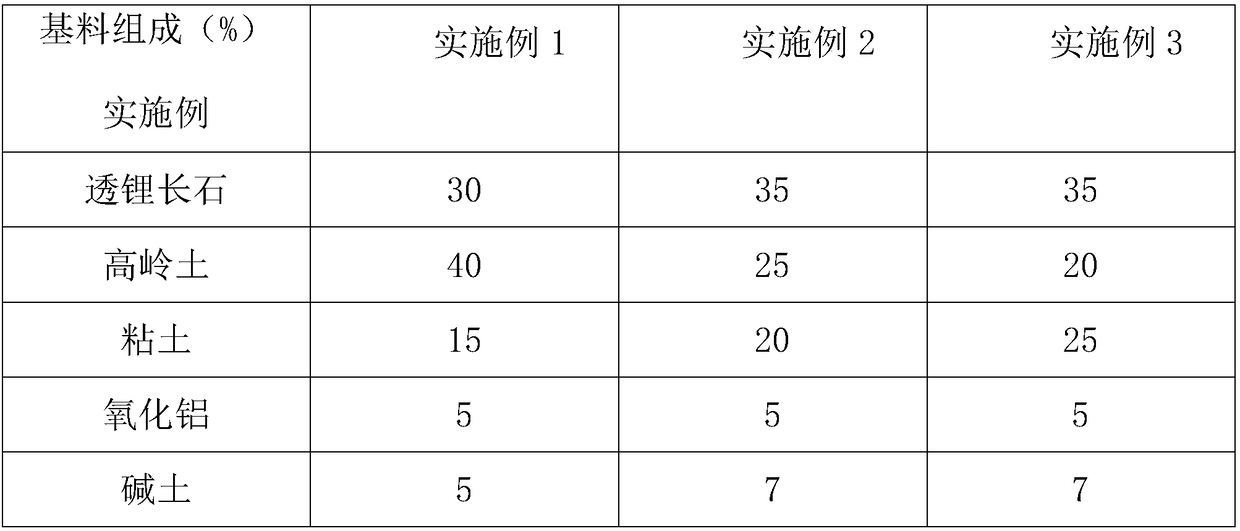

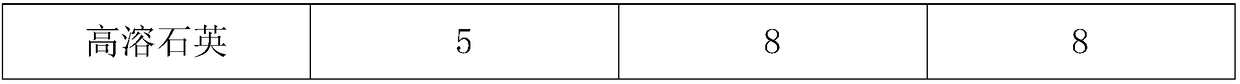

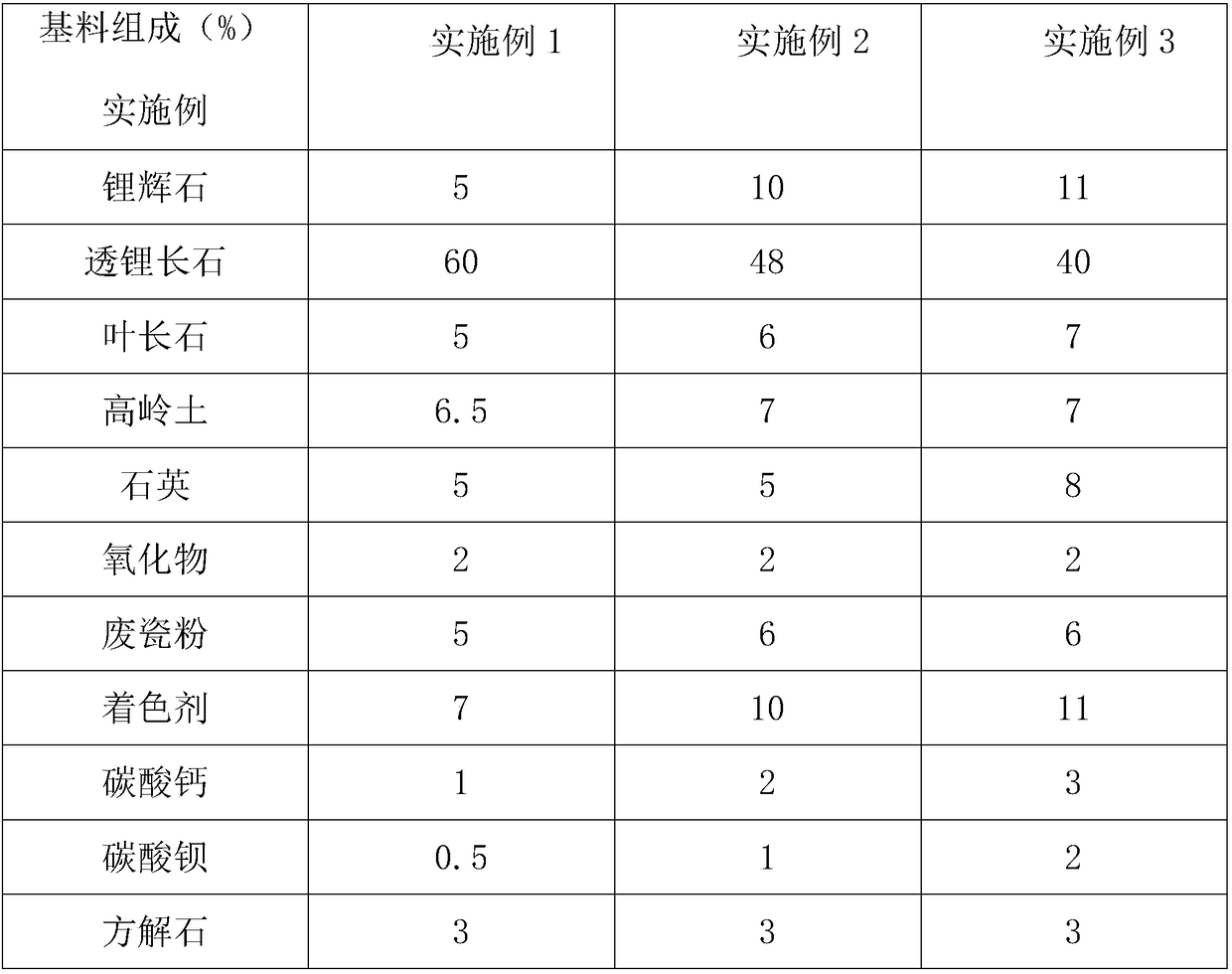

Embodiment 1

[0032] A black-glazed heat-resistant ceramic pot, including a ceramic pot body and a black glaze, the base material of the ceramic pot body is composed of: 30% petalite feldspar, 40% kaolin, 15% clay, 5% alumina, alkaline earth 5%, high soluble quartz 5%, the black glaze base material is composed of: 5% spodumene, 60% petalite, 5% pyrophyllite, 6.5% kaolin, 5% quartz, 2% oxide, 5% of waste porcelain powder, 7% of colorant, 1% of calcium carbonate, 0.5% of barium carbonate, 3% of calcite, the oxide in the black glaze base material is a mixture of barium carbonate, zinc oxide, lead oxide, etc., and the carbonate The mixing ratio of barium, zinc oxide and lead oxide is 1:2:1, and the colorant in the black glaze base material is a mixture of chromium oxide, iron oxide and manganese oxide, wherein the content of chromium oxide is 20%, and the content of iron oxide is 50% , manganese oxide content 30%.

[0033] The present invention also provides a method for preparing a black-glaz...

Embodiment 2

[0047]A black-glazed heat-resistant ceramic pot, comprising a ceramic pot body and a black glaze, the base material of the ceramic pot body is composed of: 35% petalite feldspar, 25% kaolin, 20% clay, 5% alumina, alkaline earth 7%, high soluble quartz 8%, the black glaze base material is composed of: 10% spodumene, 48% petalite, 6% pyrophyllite, 7% kaolin, 5% quartz, 2% oxide, 6% of waste porcelain powder, 10% of colorant, 2% of calcium carbonate, 1% of barium carbonate, 3% of calcite, the oxide in the black glaze base material is a mixture of barium carbonate, zinc oxide, lead oxide, etc., and the carbonate The mixing ratio of barium, zinc oxide and lead oxide is 1:2:1, and the colorant in the black glaze base material is a mixture of chromium oxide, iron oxide and manganese oxide, wherein the content of chromium oxide is 25%, and the content of iron oxide is 40% , manganese oxide content 35%.

[0048] The present invention also provides a method for preparing a black-glazed...

Embodiment 3

[0062] A black-glazed heat-resistant ceramic pot, comprising a ceramic pot body and a black glaze, the base material of the ceramic pot body is composed of: 35% petalite feldspar, 20% kaolin, 25% clay, 5% alumina, alkaline earth 7%, high soluble quartz 8%, the black glaze base material is composed of: 11% spodumene, 40% petalite, 7% pyrophyllite, 7% kaolin, 8% quartz, 2% oxide, 6% of waste porcelain powder, 11% of colorant, 3% of calcium carbonate, 2% of barium carbonate, and 3% of calcite. The oxide in the black glaze base material is a mixture of barium carbonate, zinc oxide, lead oxide, etc., and the carbonate The mixing ratio of barium, zinc oxide and lead oxide is 1:2:1, and the colorant in the black glaze base material is a mixture of chromium oxide, iron oxide and manganese oxide, wherein the content of chromium oxide is 35%, and the content of iron oxide is 30% , manganese oxide content 35%.

[0063] The present invention also provides a method for preparing a black-g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com