Multicellular system for regulating products by changing ventilating condition and fermenting method

A fermentation method and multi-cell technology, applied in the field of bioengineering, to achieve the effects of strong tolerance to complex substrates, reduced raw material costs, and good fermentation stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] Example 1 Enrichment and screening of domesticated 1,3-propanediol-producing multicellular system DUT08 from petroleum wastewater

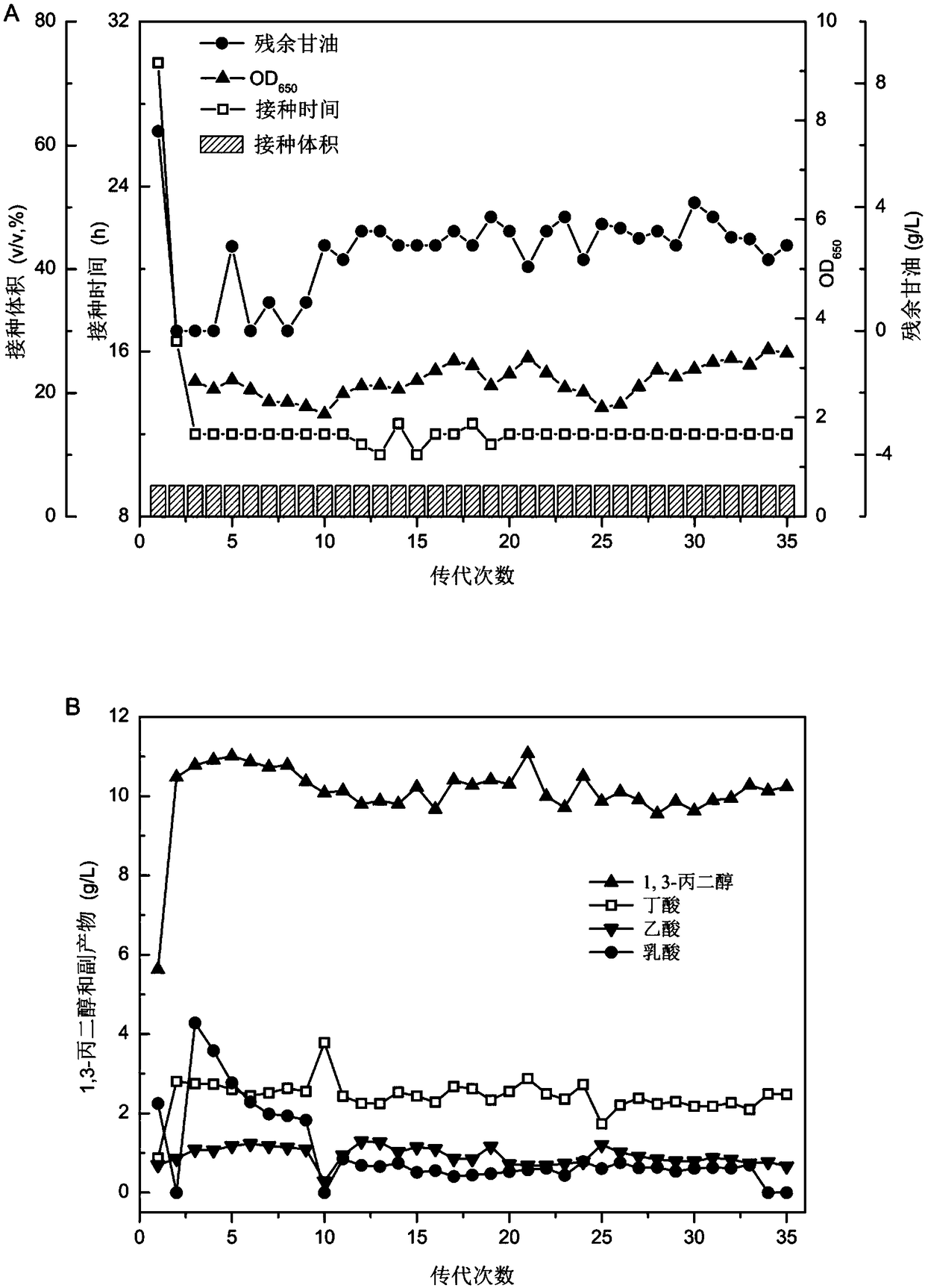

[0043] The sample was collected from a petroleum wastewater treatment plant in Dalian, and 10 mL was inserted into the seed medium, and cultivated at 37°C and 200 r / min until more than half of the substrate was consumed (about 30 hours) to obtain a primary culture. Transfer the primary culture to another seed medium at a 5% inoculum size, cultivate until more than half of the substrate is consumed (about 16.5 hours) to obtain a secondary culture, and continue to transfer the secondary culture at a 5% inoculum size, The transfer time was shortened to 12 hours, and then the 12-hour subculture cycle was continuously subcultured to the 35th generation, and a multi-cell system with stable fermentation performance was obtained. Depend on figure 1 It can be seen from A and 1B that when the multi-cell system is subcultured to the middle and late s...

Embodiment 2

[0047] Example 2 Multicellular system DUT08 microaerobic / anaerobic fermentation metabolic characteristics and substrate tolerance

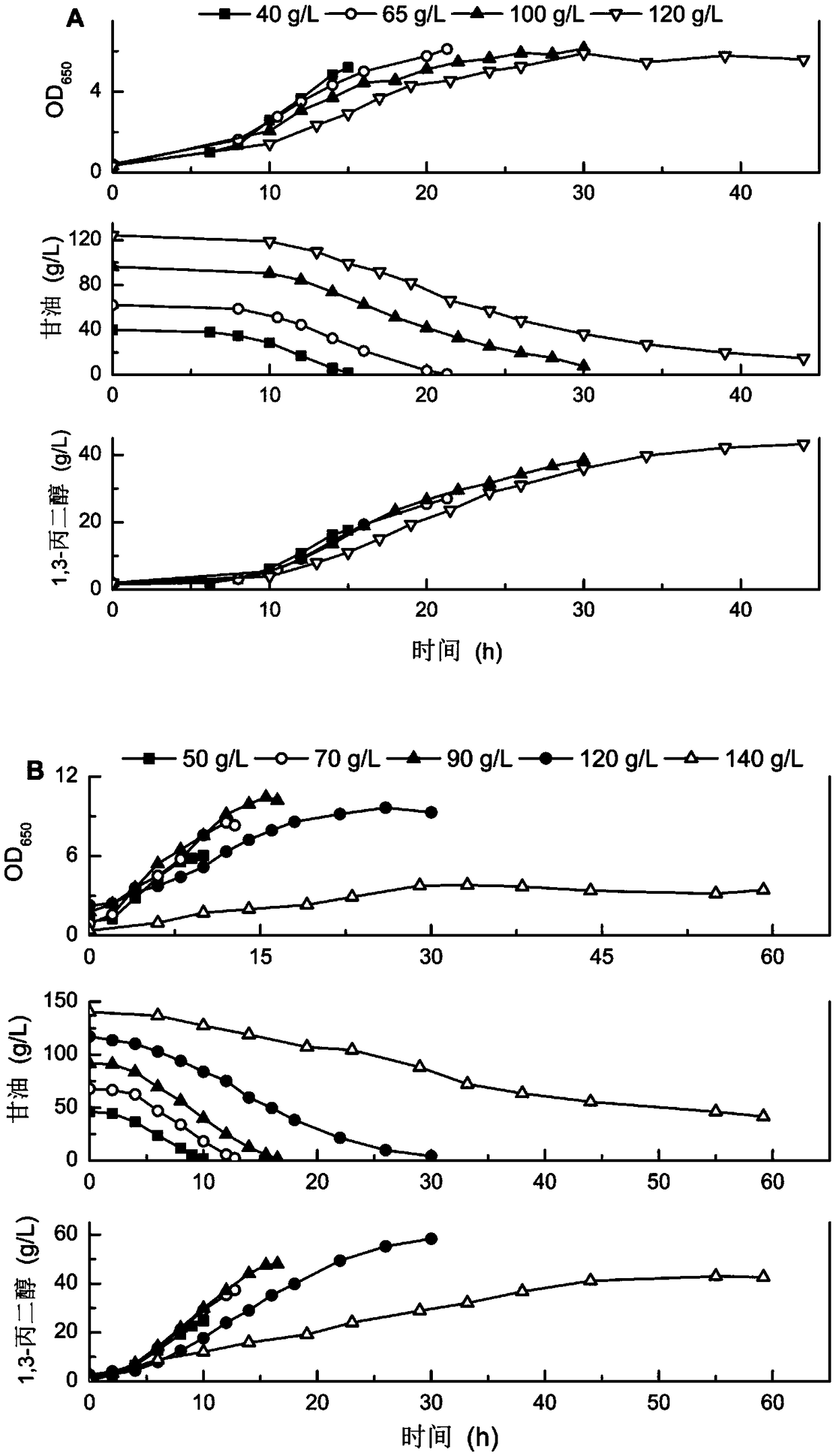

[0048] After culturing the multicellular system DUT08 obtained in Example 1 with the seed medium, it was inoculated into a 5L fermenter with 2L fermentation medium at a volume ratio of 10% for cultivation, and batch fermentation was carried out at an initial glycerol concentration of 40-140g / L (crude glycerol 53-187g / L), the results are shown in figure 2 ( figure 2 A:0.00vvm, figure 2 B: 0.02vvm). Fermentation results showed that the multicellular system DUT08 was 2 Under the condition of feed rate of 0.00vvm, the highest tolerance is 120g / L glycerol, and the fermentation products are mainly 1,3-propanediol and lactic acid. When the initial glycerol concentration was 120g / L, the concentration of 1,3-propanediol reached 43.2g / L, the concentration of lactic acid was 26.38g / L, and the total mass conversion rate of 1,3-propanediol and lactic a...

Embodiment 3

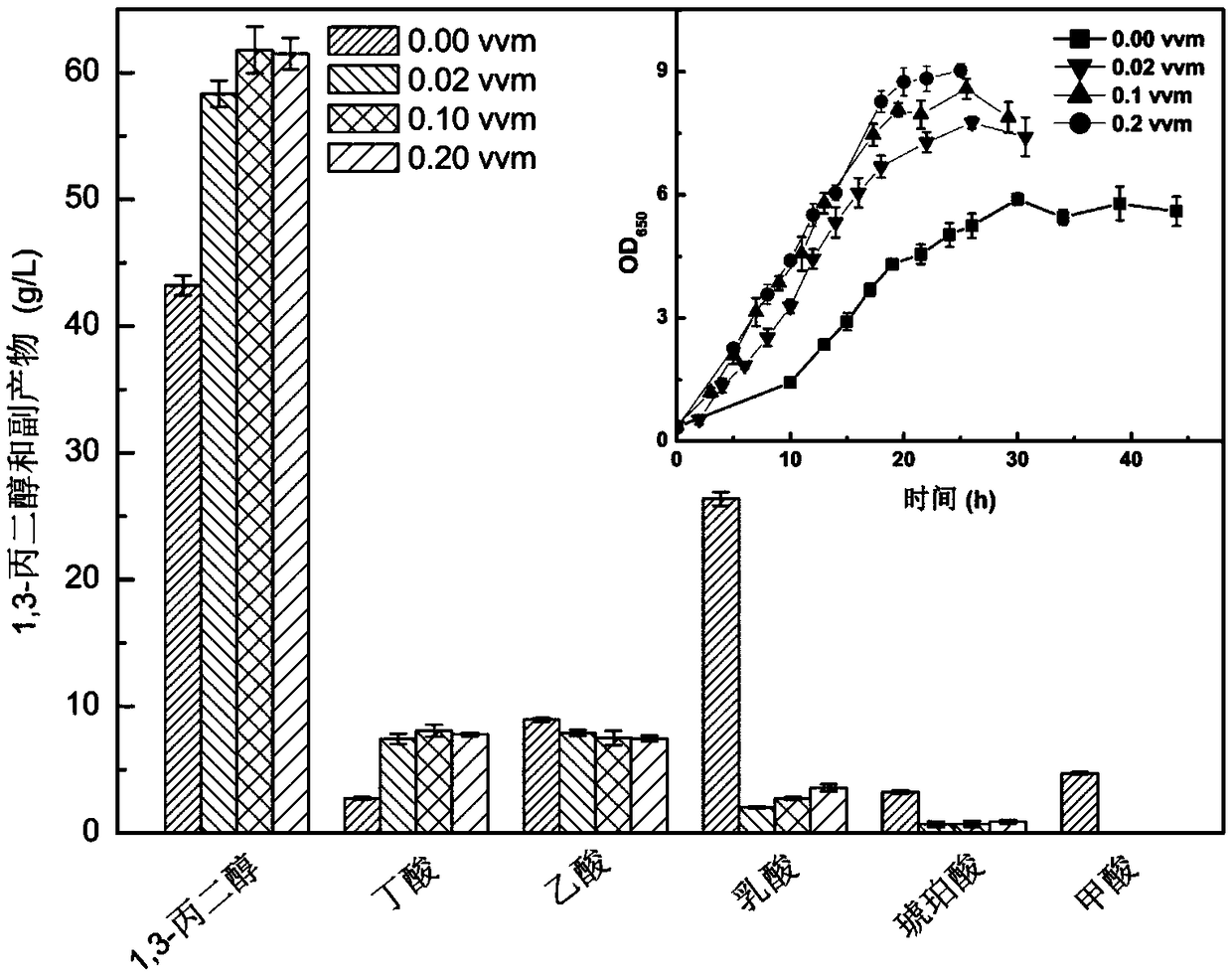

[0049] Example 3 Multicellular system DUT08 in different N 2 Growth and Metabolism at Influx

[0050] After the multicellular system DUT08 obtained in Example 1 was cultivated in the seed medium, it was inoculated into a 5L fermentor with 2L fermentation medium by 10% volume ratio for cultivation, the initial substrate concentration was 120g / L, and the ventilation rate was 0-0.2vvm, aeration for 1h and 2h before and after inoculation, see fermentation results image 3 . The fermentation results showed that with the increase of the ventilation rate, the ability of the multi-cell system DUT08 to ferment and produce 1,3-propanediol gradually increased. When the ventilation rate was 0.1vvm, the highest yield of 1,3-propanediol was 61.80g / L. It is 0.55g / g, and the production intensity is 2.12g / (L·h). When the ventilation rate increased to 0.2vvm, the output of 1,3-propanediol was 61.49g / L, the conversion rate was 0.55g / g, and the production intensity increased to 2.46g / (L·h). Wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com