Graphene PVDF composite conductive ultrafiltration membrane as well as preparation and contaminant removing methods of ultrafiltration membrane

A composite conductive and graphene technology, applied in chemical instruments and methods, ultrafiltration, membrane technology, etc., can solve the problems of low cleaning efficiency and achieve high cleaning efficiency and good conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

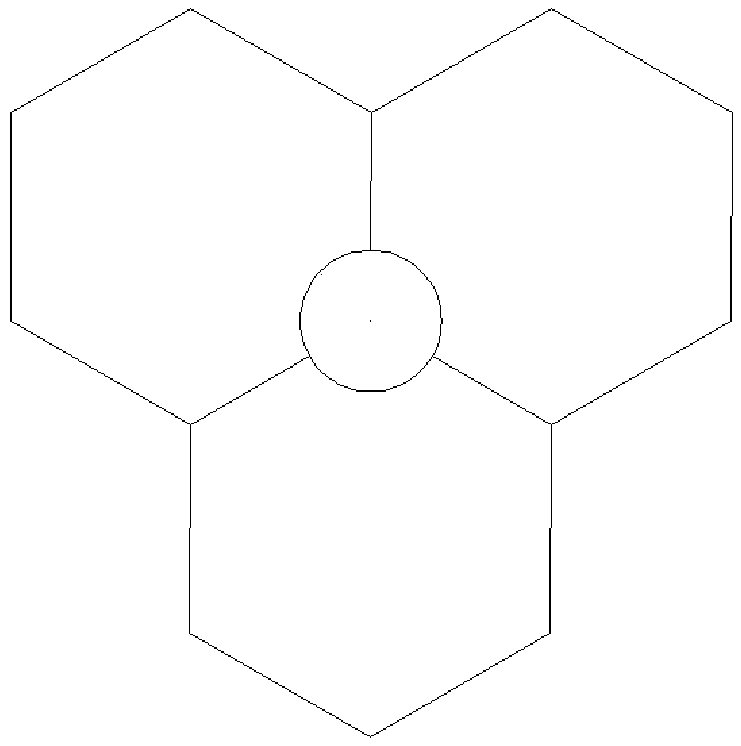

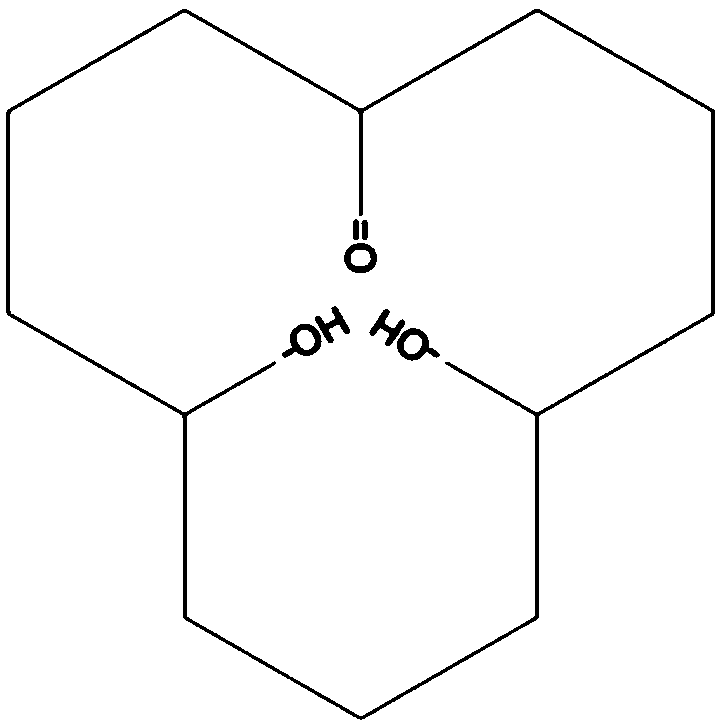

Image

Examples

Embodiment 1

[0052] A preparation method of graphene PVDF composite conductive ultrafiltration membrane, specifically as follows:

[0053] Step 1, preparation of copper foil with a thin layer of graphene attached

[0054] Step 1.1, select a piece with a size of 2×2cm 2 Copper foil of the same size, immersed in 30% hydrogen peroxide for 30 minutes, the reaction temperature is 60°C, the surface of the copper foil is oxidized, and a laser drilling machine is used to uniformly etch 200×200 matrix pits on the surface of the copper oxide, but the copper foil cannot be perforated . The area of a single pit is about 1 μm in diameter, and the depth is about 5 μm.

[0055] Step 1.2, put the copper foil prepared in step 1.1 in acetone for 5 minutes and wash it three times with absolute ethanol to remove the organic matter on the surface of the copper foil, then take it out and ultrasonically wash it in deionized water for 10 minutes, remove the organic solution used for cleaning, and ensure The ...

Embodiment 2

[0074] A preparation method of graphene PVDF composite conductive ultrafiltration membrane, specifically as follows:

[0075] Step 1, preparation of copper foil with graphene thin layer

[0076] Step 1.1, select a piece with a size of 2×2cm 2Copper foil of the same size, immersed in 30% hydrogen peroxide for 30 minutes, the reaction temperature is 60°C, the surface of the copper foil is oxidized, and a laser drilling machine is used to uniformly etch 100×100 matrix pits on the surface of the copper oxide, but the copper foil cannot be perforated . The area of a single pit is about a circular pit with a diameter of 4 μm, and the depth is about 10 μm.

[0077] In step 1.2, soak the treated copper foil in acetone for 5 minutes, then wash it with absolute ethanol for 3 times, and then soak it in deionized water for 10 minutes sonication.

[0078] In step 1.3, immerse the copper foil treated in step 1.2 in a 0.2 mol / L hydrochloric acid solution for 2 minutes to remove the oxid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com