Nanoscale intercalated hydrotalcite catalyst as well as preparation method and application thereof

A catalyst and nano-scale technology, applied in the direction of catalyst activation/preparation, carbon monoxide reaction preparation, chemical instruments and methods, etc., can solve the problems of low conversion rate and high raw material cost, and achieve the effect of easy operation, simple preparation method and stable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0035] A kind of nanoscale intercalation hydrotalcite catalyst, its preparation method can comprise the following steps:

[0036] Step A, mix the soluble salt with catalytic activity, the soluble salt of trivalent metal and alkaline substance, make the pH value of mixed solution be 7~13 (this pH value is preferably 8~11), and with reaction temperature 60-160° C. (the reaction temperature is preferably 80-140° C.), and react for 6-48 hours to prepare a catalyst precursor with a pH value of 7-13 (the pH value is preferably 8-11). Wherein, the soluble salt with catalytic activity and the soluble salt of the trivalent metal can be in any ratio, and the amount of the alkaline substance is enough so that the pH of the mixed solution is 7-13.

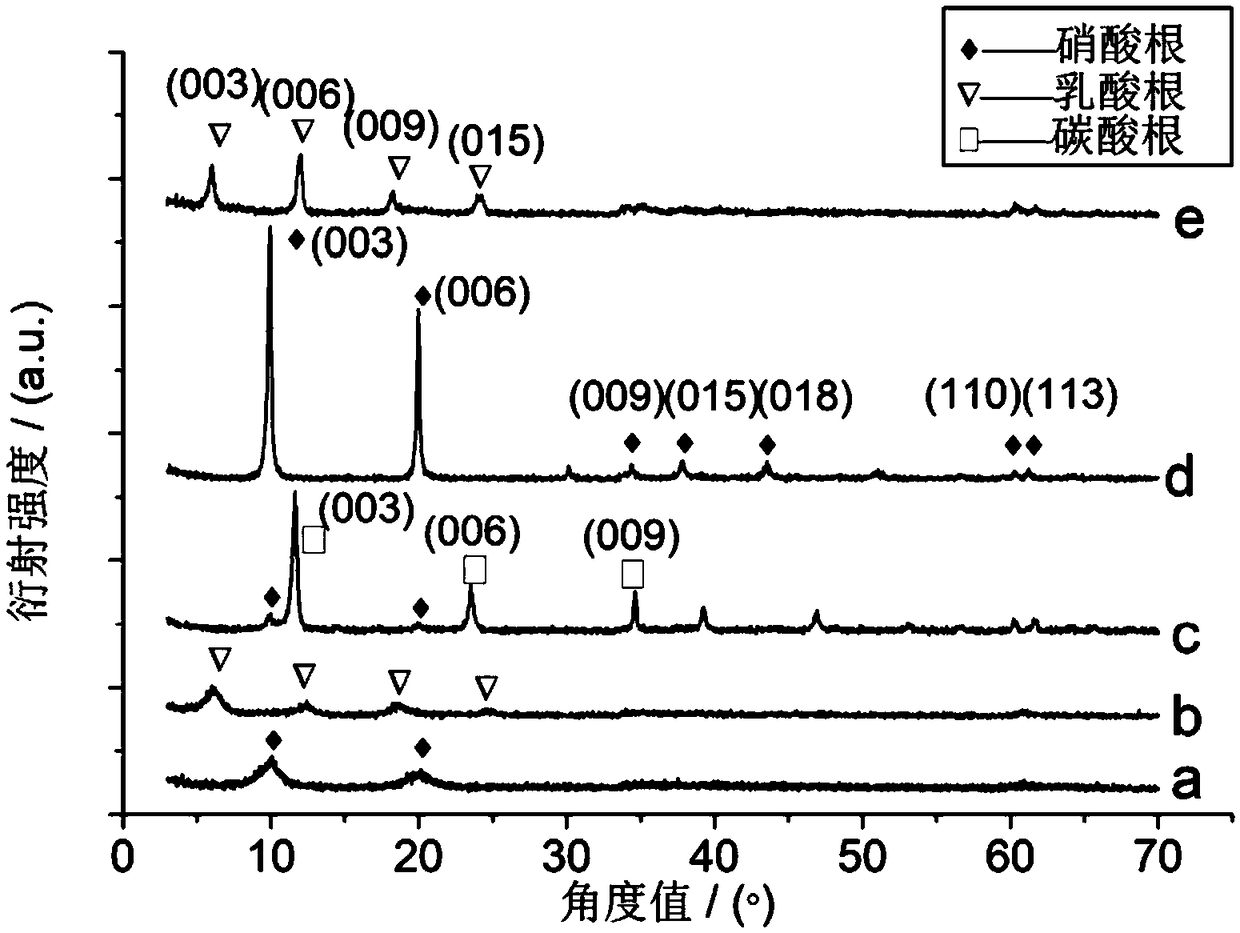

[0037] Step B, adding macromolecular organic matter to the catalyst precursor for intercalation reaction (the intercalation reaction can adopt the intercalation reaction in the prior art, that is, when the main reactant is a layered structure,...

Embodiment approach

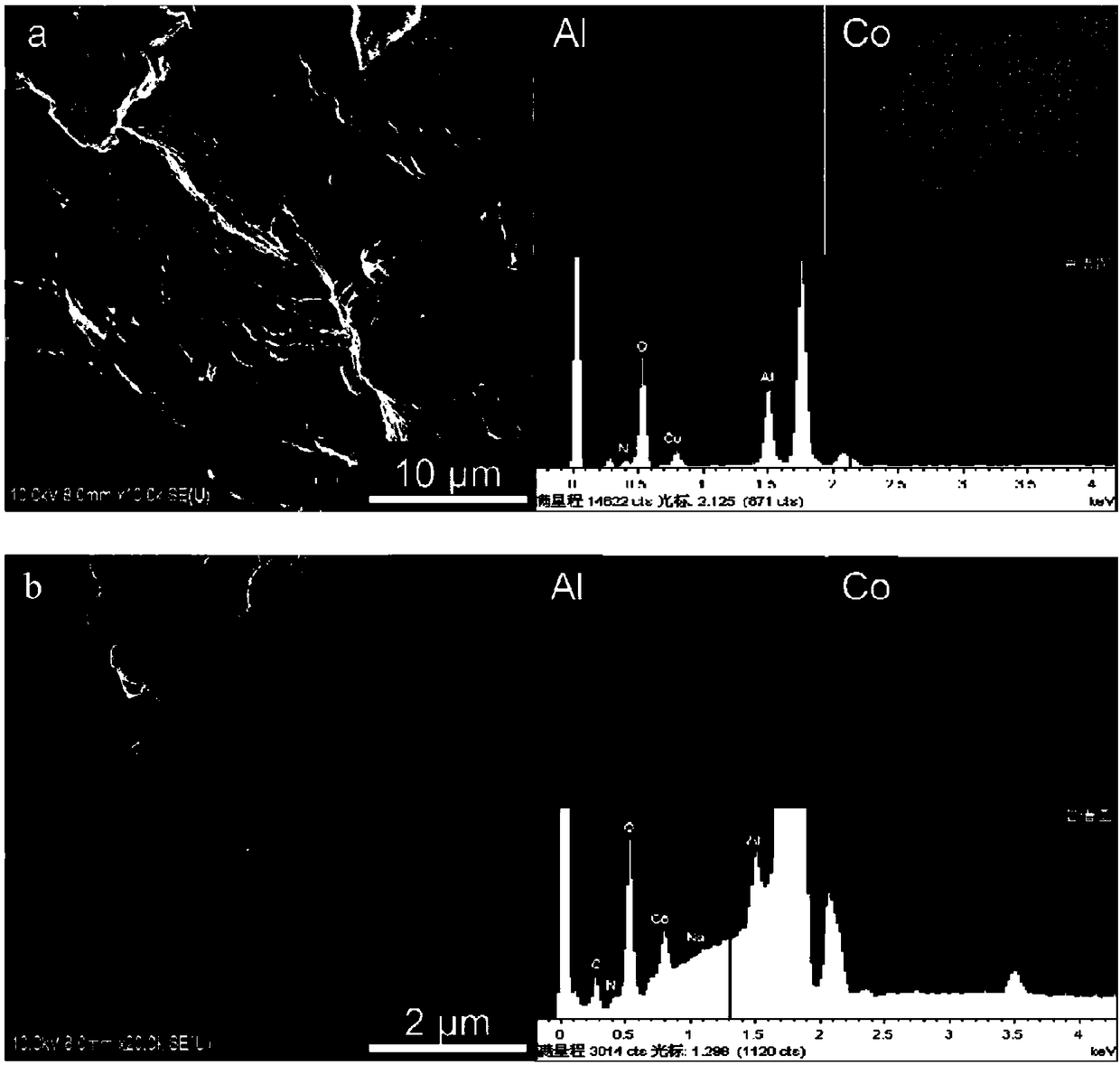

[0041](1) The soluble salt with catalytic activity is a soluble salt of at least one of Co, Fe, Ru, Rh, Ni; for example: the soluble salt with catalytic activity can be Co(NO 3 ) 2 ·6H 2 O, Fe(NO 3 ) 2 9H 2 O, Ni(NO 3 ) 2 ·6H 2 O or RuCl 3 ·3H 2 O.

[0042] (2) the soluble salt of described trivalent metal can be the soluble salt of at least one in aluminum ion or chromium ion; For example: the soluble salt of described trivalent metal can be Al(NO 3 ) 3 9H 2 O.

[0043] (3) The alkaline substance can use NH 3 ·H 2 O, NaOH, Na 2 CO 3 , urea, and at least one of hexamethylenetetramine.

[0044] (4) The macromolecular organic matter is at least one of sodium lactate, short-chain alcohol, formamide and derivatives thereof.

[0045] (5) The reducing gas is at least one of hydrogen and carbon monoxide.

[0046] (7) The peeling can use one or a combination of vibration, ultrasound, and centrifugation.

[0047] Specifically, the preparation method of the nanoscale...

Embodiment 1

[0054] A kind of nanoscale intercalation hydrotalcite catalyst, its preparation method can comprise the following steps:

[0055] Step a1, 3.638g of Co(NO 3 ) 2 ·6H 2 O, 2.345g of Al(NO 3 ) 3 9H 2 The urea of O, 2.289g all adds to 50mL and removes CO 2 in deionized water, fully stirred evenly, and then placed in a 100mL hydrothermal kettle, and reacted for 48h at a reaction temperature of 80°C, thereby preparing a catalyst precursor with a pH value of 8-11.

[0056] Step b1, adding 20 mL of sodium lactate to the catalyst precursor for intercalation reaction, the reaction temperature is 70° C., and the reaction time is 24 h, so as to prepare a catalyst precursor for intercalation organic matter.

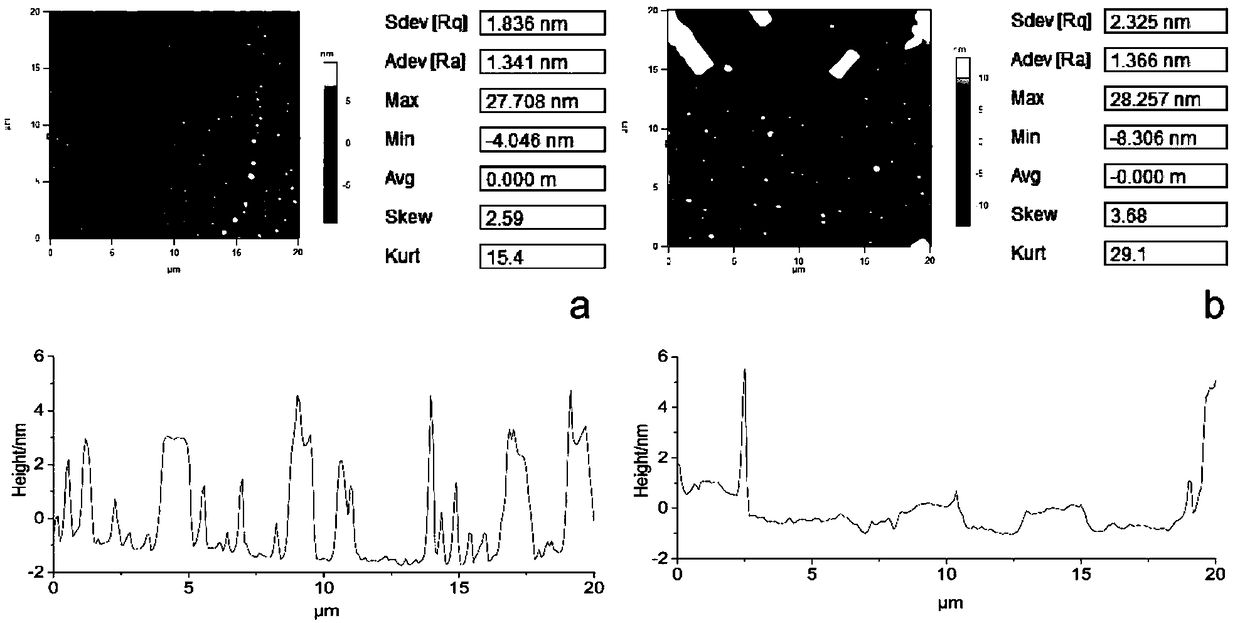

[0057] Step c1. Add 20 mL of deionized water to the catalyst precursor of the intercalated organic matter, place it in a high-speed centrifuge, and centrifuge it at a speed of 6000 r / min for 30 min to remove solids, thereby preparing a stripping solution.

[0058] Step d1, us...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com