Preparation method for copper nanorod-reinforced asphalt root blocking material applied to planted roof

A copper nanorod and root-blocking technology, which is applied in the field of preparation of copper nanorod-enhanced asphalt planting roof root-blocking materials, can solve problems such as smoke, achieve environmental friendliness, reduce smoke emissions, and reduce construction difficulty.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

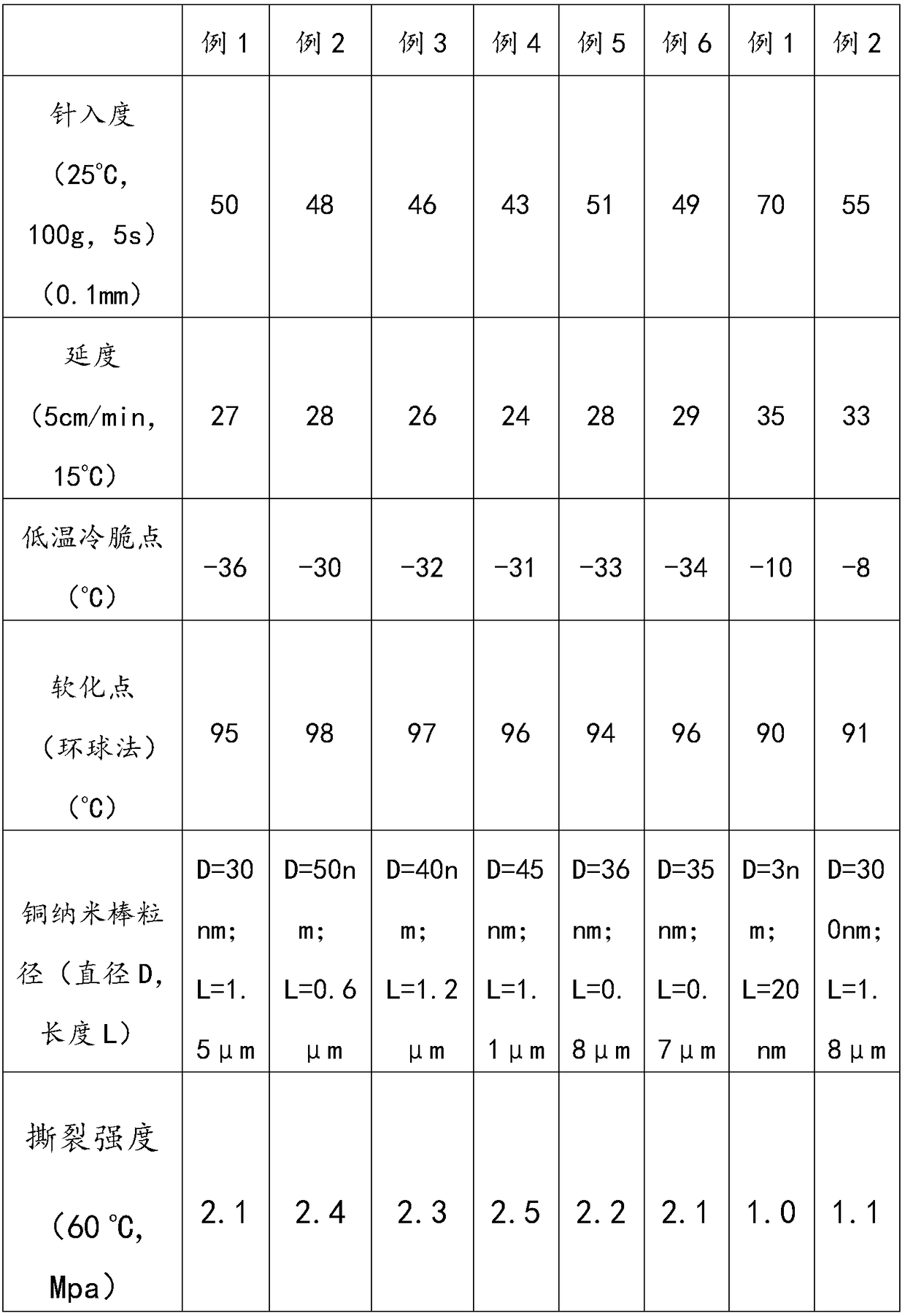

Embodiment 1

[0026] Step 1: Under mechanical stirring, dissolve 40 parts of copper chloride in a mixed solution of 50 parts of ethanol and 50 parts of deionized water, add 2 parts of ammonia water, add 10 parts of sodium borohydride, and then add 3 parts of 1% Gelatin hydrolyzate and 2 parts of polyvinylpyrrolidone were dispersed and dissolved for 0.5 hours. The mixed solution is heated to a temperature of 70-80 degrees Celsius, reacted for 2 hours, centrifuged, and washed with deionized water and ethanol to obtain copper nanorods.

[0027] Step 2: Take 10 parts of the prepared copper nanorods, add 30 parts into 5% low molecular weight polystyrene chloroform solution, heat the temperature to 40 degrees Celsius, and keep mechanical stirring for 1 hour, and obtain polystyrene modified copper nanorods .

[0028] Step 3: Add 20 parts of diesel oil to 100 parts of base petroleum asphalt, and change the base petroleum asphalt into a viscous flowable slurry by stirring and dissolving at a temper...

Embodiment 2

[0032] Step 1: Under mechanical stirring, dissolve 50 parts of copper chloride in a mixed solution of 50 parts of ethanol and 50 parts of deionized water, add 4 parts of ammonia water, and add 15 parts of sodium borohydride, then add 6 parts of 1% Gelatin hydrolyzate and 4 parts of polyvinylpyrrolidone were dispersed and dissolved for 1 hour. The mixed solution was heated to a temperature of 80 degrees Celsius, reacted for 4 hours, centrifuged, and washed with deionized water and ethanol to obtain copper nanorods.

[0033] Step 2: Take 20 parts of the prepared copper nanorods, add 40 parts into 5% low molecular weight polystyrene chloroform solution, heat the temperature to 60 degrees Celsius, and keep mechanical stirring for 2 hours, obtain polystyrene modified copper nanorods .

[0034] Step 3: Add 30 parts of diesel oil to 100 parts of base petroleum asphalt, and through stirring and dissolving at a temperature of 50° C., change the base petroleum asphalt into a viscous fl...

Embodiment 3

[0038] Step 1: Under mechanical stirring, dissolve 45 parts of copper chloride in a mixed solution of 50 parts of ethanol and 50 parts of deionized water, add 3 parts of ammonia water, and add 13 parts of sodium borohydride, then add 4 parts of 1% Gelatin hydrolyzate and 3 parts of polyvinylpyrrolidone were dispersed and dissolved for 1 hour. The mixed solution is heated to a temperature of 70-80 degrees Celsius, reacted for 3 hours, centrifuged, and washed with deionized water and ethanol to obtain copper nanorods.

[0039] Step 2: Take 15 parts of the prepared copper nanorods, add 35 parts into 5% low molecular weight polystyrene chloroform solution, heat the temperature to 50 degrees Celsius, and keep mechanical stirring for 1.5 hours, and obtain polystyrene modified copper nanorods .

[0040] Step 3: Add 25 parts of diesel oil to 100 parts of base petroleum asphalt, and through stirring and dissolving at a temperature of 45° C., change the base petroleum asphalt into a visc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com