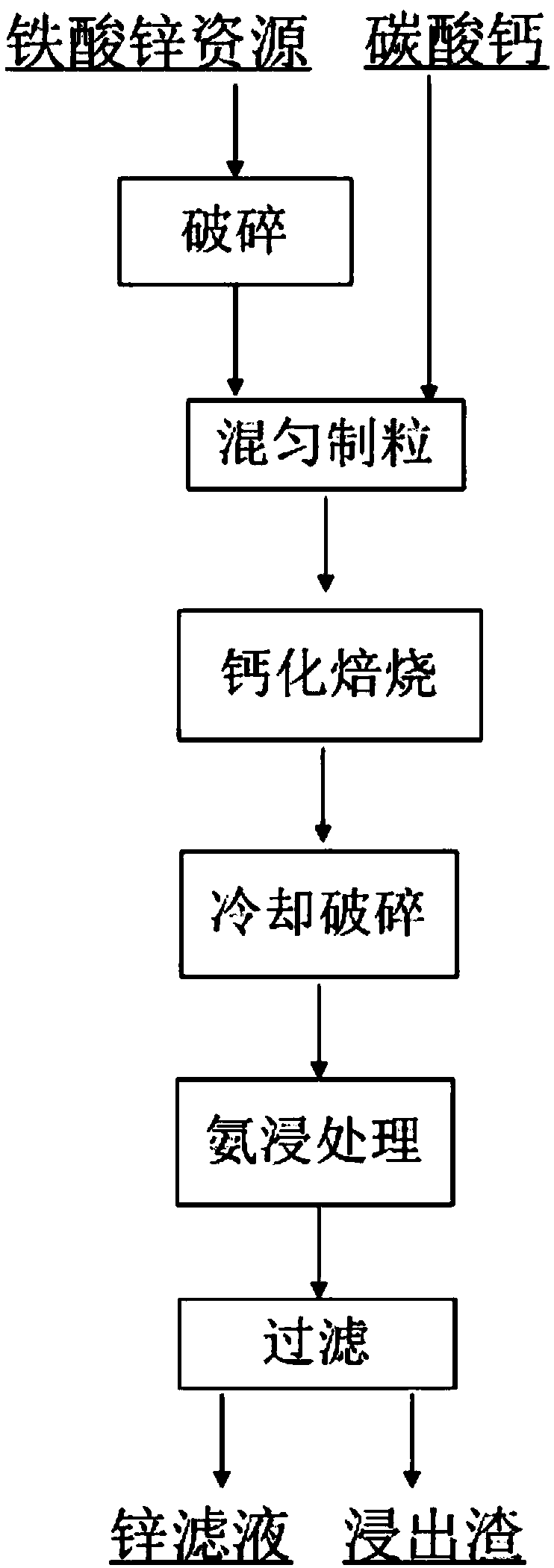

Method of recycling zinc from zinc ferrite resource by using calcium roasting-ammonia leaching process

A technology of calcification roasting and zinc ferrite, which is applied in the field of zinc recovery, can solve the problems of not developing a method for the clean and efficient utilization of zinc ferrite resources, the utilization rate of less than 20%, and the inability to effectively recover and utilize the zinc ferrite resource. The effect of easy leaching, filtration and separation, fast reaction rate and low leaching cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Zinc-containing dust (TZn 5.67%, ZnFe 2 o 4 55.72%), crush the raw ore to -1mm, add calcium carbonate, control the molar ratio of effective CaO content in calcium carbonate to zinc ferrite to 2.4:1, mix well and granulate into small balls of 3-20mm, mix The material is placed in a rotary kiln for calcification and roasting to complete the reconstruction of mineral phases. The roasting temperature is 1220°C, the roasting time is 120 minutes, cooled naturally, broken to -3mm, and then subjected to ammonia leaching treatment. The ammonia leaching system is: the solid-liquid ratio is 100g / L, the leaching temperature is 40°C, the leaching time is 120min, and the leaching solution is NH 4 Cl-NH 3 ·H 2 O solution (NH 4 Cl and NH 3 ·H 2 The molar concentration ratio of O is 1:1), the total ammonia concentration in the leaching solution is 6mol / L, and the zinc leaching rate is 93.65% after the leaching solution is filtered.

Embodiment 2

[0032] Zinc-containing dust (TZn 5.67%, ZnFe 2 o 4 55.72%), crush the raw ore to -1mm, add calcium carbonate, control the molar ratio of effective CaO content in calcium carbonate to zinc ferrite to 2.4:1, mix well and granulate into small balls of 3-20mm, mix The material is placed in a rotary kiln for calcification and roasting to complete the reconstruction of mineral phases. The roasting temperature is 1240 ° C, the roasting time is 120 minutes, natural cooling, crushed to -3mm, and ammonia leaching treatment. The ammonia leaching system is: the solid-liquid ratio is 120g / L, the leaching temperature is 40°C, the leaching time is 100min, and the leaching solution is NH 4 Cl-NH 3 ·H 2 O solution (NH 4 Cl and NH 3 ·H 2 The molar concentration ratio of O is 1:1), the total ammonia concentration in the leaching solution is 6mol / L, and the zinc leaching rate is 93.31% after the leaching solution is filtered.

Embodiment 3

[0034] Zinc-containing dust (TZn 5.67%, ZnFe 2 o 4 55.72%), crush the raw ore to -1mm, add calcium oxide, control the molar ratio of effective CaO content to zinc ferrite to 2.5:1, mix well and granulate into small balls of 3-20mm, place the mixture in Carry out calcification and roasting in a rotary kiln to complete mineral phase reconstruction. The roasting temperature is 1220°C and the roasting time is 120 minutes. Natural cooling, crushing to -3mm, and ammonia leaching treatment are carried out. The ammonia leaching system is: the solid-to-liquid ratio is 100g / L, The leaching temperature is 60°C, the leaching time is 110min, and the leaching solution is NH 4 Cl-NH 3 ·H 2 O solution (NH 4 Cl and NH 3 ·H 2 The molar concentration ratio of O is 1:1), the total ammonia concentration in the leaching solution is 6mol / L, and the zinc leaching rate is 94.71% after the leaching solution is filtered.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com