Preparation method and photocatalytic hydrogen production application of CdS-PAN/graphene composite nano fiber

A graphene composite, nanofiber technology, applied in the direction of organic compound/hydride/coordination complex catalyst, physical/chemical process catalyst, hydrogen production, etc., can solve the problems of CdS particle waste, small specific surface area, etc. The effect of inhibiting agglomeration, high specific surface area, and increasing the rate of hydrogen production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

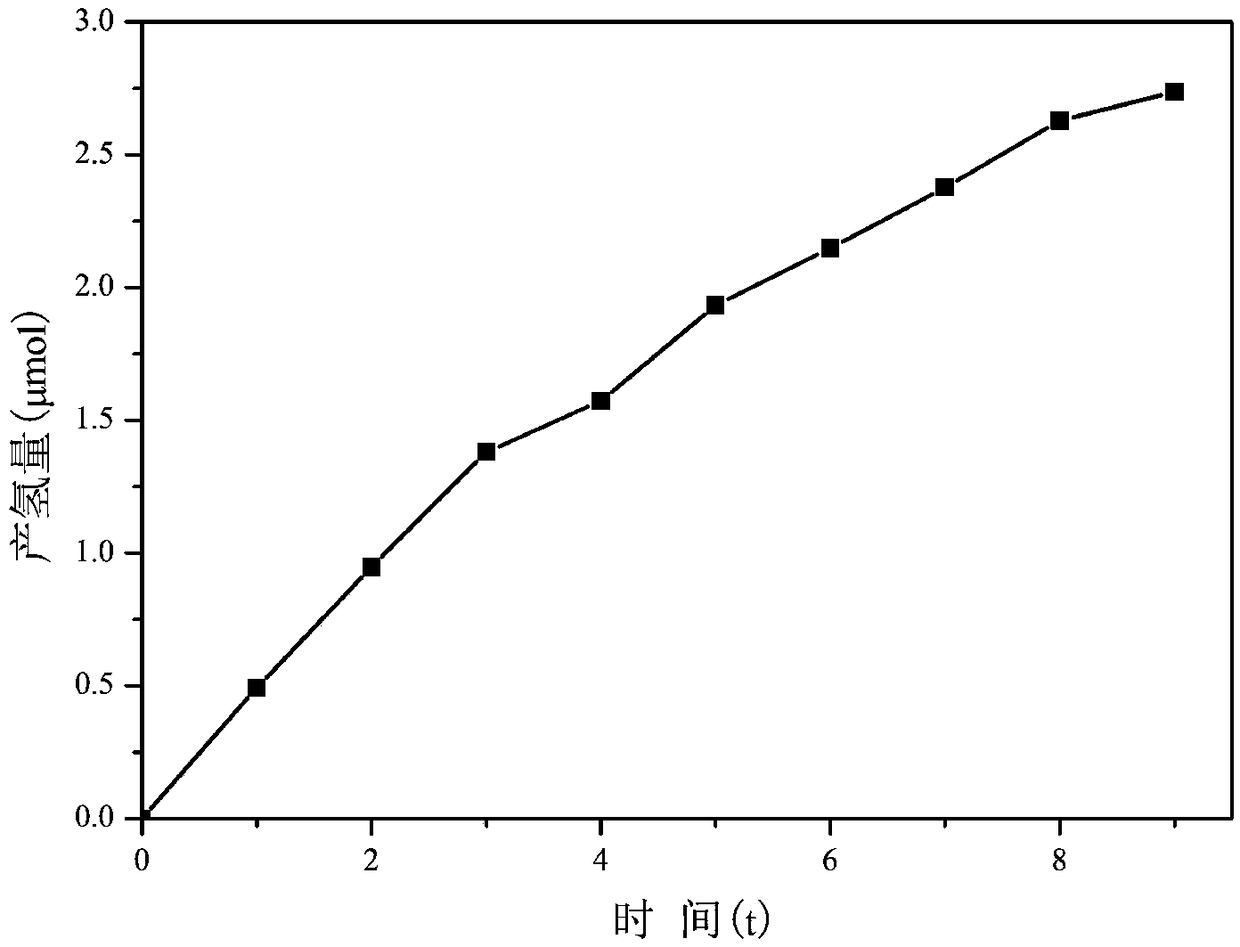

Image

Examples

Embodiment 1

[0033] 1) Preparation of S-n-propyl-S'-(α-methyl-α'-acetic acid)-trithiocarbonate (PTTC)

[0034] Add 10g of 3-mercaptoacetic acid and 100g of distilled water into a 500mL three-necked flask, adjust the pH value to 12 with 1mol / L sodium hydroxide, add 5g of carbon disulfide dropwise under magnetic stirring conditions, and react for 12h. After the reaction, continue to drop 12g of 1-bromopropane and continue to react for 12h. The product is acidified with 3mol / L hydrochloric acid, suction filtered, washed, and dried to obtain S-n-propyl-S'-(α-methyl-α'-acetic acid )-trithiocarbonate (PTTC).

[0035] 2) Preparation of CdS-PTTC

[0036] Add 1 g of cadmium hydroxysulfide (CdS-OH), 0.5 g of PTTC and 0.915 g of methylaminopyridine into 100 mL of N,N-dimethylformamide solution, and dissolve with magnetic stirring at 0°C for 1 h under nitrogen protection. Add 2.6 g of dicyclohexylcarbodiimide to the above solution, and continue the magnetic stirring reaction at room temperature for ...

Embodiment 2

[0044] 1) Preparation of S-n-propyl-S'-(α-methyl-α'-acetic acid)-trithiocarbonate (PTTC)

[0045] Add 10g of 3-mercaptoacetic acid and 100g of distilled water into a 500mL three-necked flask, adjust the pH value to 12 with 1mol / L sodium hydroxide, add 5g of carbon disulfide dropwise under magnetic stirring conditions, and react for 12h. After the reaction, continue to drop 12g of 1-bromopropane and continue to react for 12h. The product is acidified with 3mol / L hydrochloric acid, suction filtered, washed, and dried to obtain S-n-propyl-S'-(α-methyl-α'-acetic acid )-trithiocarbonate (PTTC).

[0046] 2) Preparation of CdS-PTTC

[0047] Add 1 g of cadmium hydroxysulfide (CdS-OH), 0.5 g of PTTC and 0.915 g of methylaminopyridine into 100 mL of N,N’-dimethylformamide solution, and dissolve with magnetic stirring at 0°C for 1 h under nitrogen protection. Add 2.6 g of dicyclohexylcarbodiimide to the above solution, and continue the magnetic stirring reaction at room temperature for...

Embodiment 3

[0055] 1) Preparation of S-n-propyl-S'-(α-methyl-α'-acetic acid)-trithiocarbonate (PTTC)

[0056] Add 10g of 3-mercaptoacetic acid and 100g of distilled water into a 500mL three-necked flask, adjust the pH value to 12 with 1mol / L sodium hydroxide, add 5g of carbon disulfide dropwise under magnetic stirring conditions, and react for 12h. After the reaction, continue to drop 12g of 1-bromopropane and continue to react for 12h. The product is acidified with 3mol / L hydrochloric acid, suction filtered, washed, and dried to obtain S-n-propyl-S'-(α-methyl-α'-acetic acid )-trithiocarbonate (PTTC).

[0057] 2) Preparation of CdS-PTTC

[0058] Add 1 g of cadmium hydroxysulfide (CdS-OH), 0.5 g of PTTC and 0.915 g of methylaminopyridine into 100 mL of N,N’-dimethylformamide solution, and dissolve with magnetic stirring at 0°C for 1 h under nitrogen protection. Add 2.6 g of dicyclohexylcarbodiimide to the above solution, and continue the magnetic stirring reaction at room temperature for...

PUM

| Property | Measurement | Unit |

|---|---|---|

| energy | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com