A method for extracting and separating lutein from marigold

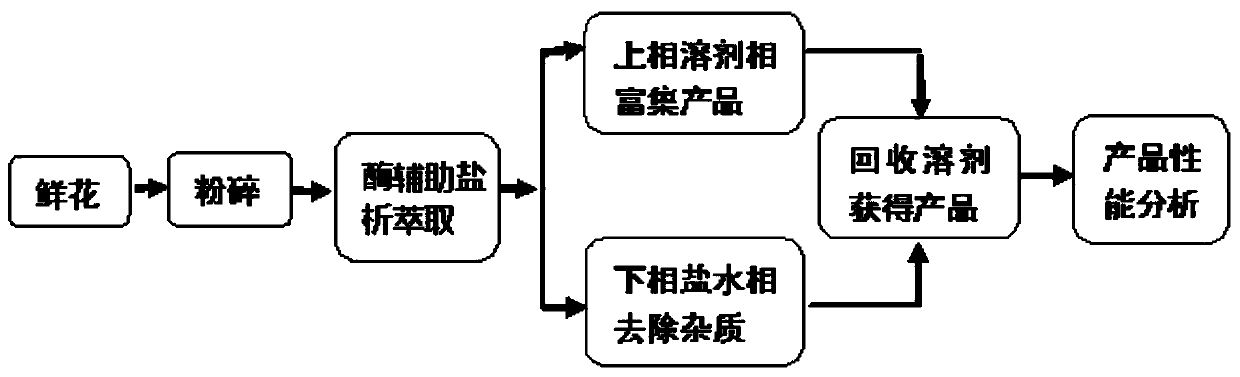

The technology of marigold and marigold flowers is applied in the field of bioengineering, which can solve the problems of large amount of solvent, environmental pollution of organic waste water, long fermentation time of flowers, etc., so as to shorten the production cycle, improve the extraction yield and simplify the production process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Example 1 Cellulase-assisted salting-out extraction of lutein from marigolds

[0038] Step 1: dry the marigold flowers in the shade away from light and ventilation, crush them through a 120-mesh sieve, and obtain the marigold flower powder;

[0039] Step 2 Weigh 0.22g of marigold flower powder, add 1.50% cellulase (mass percentage of marigold flower powder) and 4.00g of citric acid-disodium hydrogen phosphate buffer solution with pH 4.00, mix well, and enzyme in a water bath at 40°C Decompose for 120min to obtain the enzymatic solution;

[0040]Step 3 Add 1.90g of ammonium sulfate salt and 1.10g of water to the enzymolysis solution obtained in step 2, mix for 10 minutes to fully dissolve the salt, then add 3.00g of absolute ethanol, and mix for 10 minutes to form a two-phase salting out The system was left standing for 60 minutes at room temperature (20-35° C.), the lutein was enriched in the upper organic solvent phase, centrifuged at 8000 rpm for 2 minutes, and the u...

Embodiment 2

[0041] Example 2 Extraction of Lutein from Marigold by Composite Enzyme Assisted Salting-out of Cellulase and Pectinase

[0042] Step 1: dry the marigold flowers in the shade away from light and ventilation, crush them through a 120-mesh sieve, and obtain the marigold flower powder;

[0043] Step 2 takes by weighing marigold flower powder 0.22g, adds the compound enzyme that accounts for marigold flower powder mass percentage 1.50% (composite enzyme is cellulase and pectinase, and the weight ratio of cellulase and pectinase is 1:3) and 4.00 g of citric acid-disodium hydrogen phosphate buffer solution with pH 4.00, mix well, and enzymatically hydrolyze in a water bath at 40°C for 120 minutes to obtain an enzymolyzed solution;

[0044] Step 3 Add 1.90g of ammonium sulfate salt and 1.10g of water to the enzymolysis solution obtained in step 2, mix for 10 minutes to fully dissolve the salt, then add 3.00g of absolute ethanol, and mix for 10 minutes to form a two-phase salting out ...

Embodiment 3

[0045] Example 3 Pectinase-assisted salting-out extraction of lutein from marigolds

[0046] Step 1: dry the marigold flowers in the shade away from light and ventilation, crush them through a 120-mesh sieve, and obtain the marigold flower powder;

[0047] Step 2 Weigh 0.22g of marigold flower powder, add pectinase accounting for 1.50% of the mass percentage of marigold flower powder and 4.00g of citric acid-disodium hydrogen phosphate buffer solution with pH 4.00, mix well, and enzymolyze in a water bath at 40°C 120min to obtain the enzymolysis solution;

[0048] Step 3 Add 1.90g of ammonium sulfate salt and 1.10g of water to the enzymolysis solution obtained in step 2, mix for 10 minutes to fully dissolve the salt, then add 3.00g of absolute ethanol, and mix for 10 minutes to form a two-phase salting out The system was left standing for 60 minutes at room temperature (20-35° C.), the lutein was enriched in the upper organic solvent phase, centrifuged at 8000 rpm for 2 minut...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com