Silicon rubber/nano-silver-carrying modified montmorillonite nanometer antibacterial composite material and preparation method thereof

A composite material and montmorillonite technology, which is applied in the field of silicone rubber/nano-silver modified montmorillonite nano-antibacterial composite material and its preparation, can solve problems such as environmental pollution, improve antibacterial effect, shorten ion exchange time, The effect of improving compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

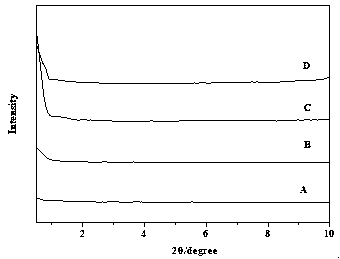

[0029] (1) Preparation of modified montmorillonite:

[0030] Prepare nano-montmorillonite and deionized water into a suspension with a mass fraction of 1.5%, add 80% of the weight of nano-montmorillonite lecithin, heat up to 70°C, stir thoroughly for 2 hours, vacuum pump to filter and separate, deionize Washing with water several times, drying in an oven at 60° C. for 24 hours, to obtain nano-montmorillonite treated with organic intercalation.

[0031] (2) Preparation of nano-silver modified montmorillonite antibacterial agent

[0032] Prepare 0.8M, 10ml silver salt aqueous solution, add 2g modified montmorillonite, and disperse evenly; add reducing agent ascorbic acid 1.36g and stabilizer polyvinylpyrrolidone 1.36g, stir at 35°C for 3 hours, vacuum pump filtration and separation, deionized water After washing several times, oven-dried at 60°C for 24 h. That is, the nano-silver modified montmorillonite antibacterial agent is obtained.

[0033] (3) Preparation of silicone ru...

Embodiment 2

[0036] Step (1) and step (2) are identical with embodiment 1.

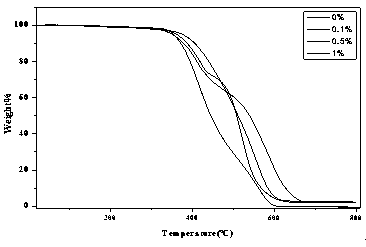

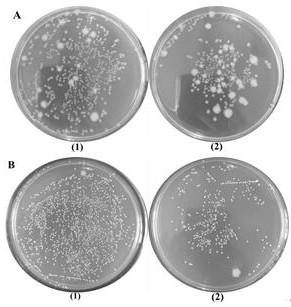

[0037] (3) Preparation of silicone rubber / silver-loaded nano-silver modified montmorillonite nano-antibacterial composite material

[0038]100 parts of silicone rubber are dispersed in cyclohexane, and 0.5 parts of nano-silver modified montmorillonite antibacterial agent is dispersed in the silicone rubber solution, mixed and stirred for 5 minutes, after stirring evenly, 7.2 parts of crosslinking agent ethyl silicate are added, Stir for 20 minutes, add 0.1 part of dibutyltin dilaurate as an accelerator, mix and stir for 20 minutes, apply it on the mold, and leave it for 7 days to prepare the silicone rubber / nano silver-loaded modified montmorillonite nano antibacterial composite material.

Embodiment 3

[0040] Step (1) and step (2) are identical with embodiment 1.

[0041] (3) Preparation of silicone rubber / silver-loaded nano-silver modified montmorillonite nano-antibacterial composite material

[0042] 100 parts of silicone rubber are dispersed in cyclohexane, 1 part of silver-loaded nano-silver modified montmorillonite antibacterial agent is dispersed in the silicone rubber solution, mixed and stirred for 5 minutes, after stirring evenly, 7.2 parts of crosslinking agent ethyl silicate are added, Stir for 20 minutes, add 0.1 part of dibutyltin dilaurate as an accelerator, mix and stir for 20 minutes, apply it on the mold, and leave it for 7 days to prepare the silicone rubber / nano silver-loaded modified montmorillonite nano antibacterial composite material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com