High-yield cultivation method for broomcorn millet

A cultivation method and technology of millet, which are applied to the high-yield cultivation field of millet, can solve problems such as drought stress prevention and control of pests and diseases, difficulty in increasing yield, and achieve the effects of reducing agricultural operations, increasing nutritional value and commodity value, and saving resources.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

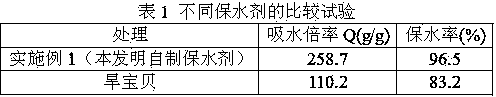

[0022] Example 1: Water-retaining performance test of special water-retaining agent for broomcorn millet

[0023] In mid-April 2017, in the laboratory of our research team, the preparation of special water-retaining agent for broomcorn millet and the water-retaining performance test were carried out: the ingredients of raw materials were recorded by weight: broomcorn millet straw 65, acrylic acid 650, glacial acetic acid 30, potassium hydroxide 325, Ionized water 195, ammonium persulfate 13, epichlorohydrin 0.65; the specific preparation steps are: (1) dry the broomcorn stalks in the air, grind them with a grinder, and sieve them for later use; (2) at room temperature, in a nitrogen-protected In the reaction kettle, add acrylic acid, glacial acetic acid and deionized water according to the weight ratio of the above ingredients, add 25% potassium hydroxide aqueous solution while stirring, and adjust the neutralization degree to 60%-70%; stir evenly for 30 minutes to make it full...

Embodiment 2

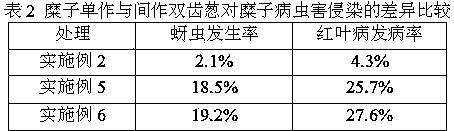

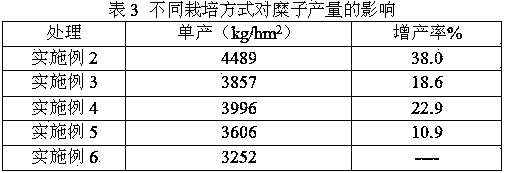

[0031] Embodiment 2: field planting test of the present invention

[0032] From October 2016 to September 2017, the research team conducted the field planting experiment of the present invention on Daxing Farm, Wengniute Banner, Chifeng City, Inner Mongolia Autonomous Region. 440mm, and most of them are concentrated in July-August, accounting for about 60% of the annual rainfall, which is relatively consistent with the water demand period of millet; the variety of millet used is Neimi No. 9: the specific implementation method is as follows:

[0033] 1. Select stubble for soil preparation, apply self-made basal fertilizer in strips and make ridges: the flat land with leguminous crops in the previous stubble is preferred, and the land is plowed deeply after autumn harvest to break the bottom of the plow; 10 days before sowing, apply 1500kg of self-made basal fertilizer per acre, The width of strip application is 100cm, and the spacing is 20cm; the base fertilizer is screwed into...

Embodiment 3

[0038] Embodiment 3: field conventional base manure test

[0039] From October 2016 to September 2017, our research team conducted a conventional base fertilizer test for broomcorn cultivation in Daxing Farm, Wengniute Banner, Chifeng City, Inner Mongolia Autonomous Region. The precipitation is 440 mm, and most of it is concentrated in July-August, accounting for about 60% of the annual rainfall, which is relatively consistent with the water demand period of broomcorn millet; the variety of broomcorn millet used is Neimi No. 9. The specific implementation method is as follows:

[0040] 1. Select stubble for soil preparation, apply basal fertilizer in strips and create ridges: choose the flat land with leguminous crops as the previous stubble, and plow the land deeply after autumn harvest to break the bottom of the plow; 10 days before sowing, apply 1500kg of basal fertilizer per mu in strips, The width is 100cm, and the distance is 20cm; use a rotary tiller to spin the base f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com