Method and device for removing smog in air flow

An air flow and smoke technology, applied in chemical instruments and methods, separation methods, gas treatment, etc., can solve the problems of large water consumption, large equipment investment, complex system, etc., and achieve low operating costs, low investment costs, and high processing efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

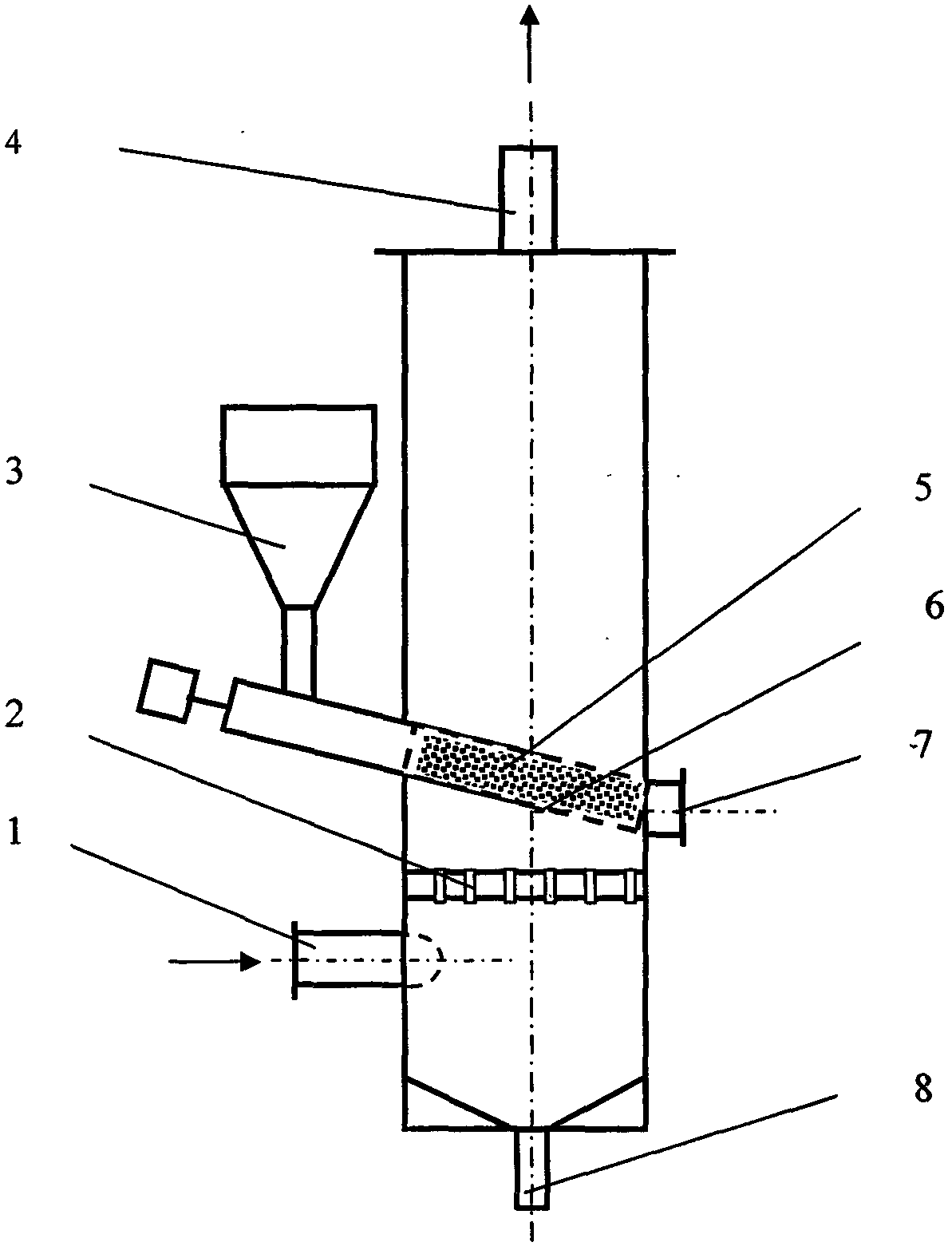

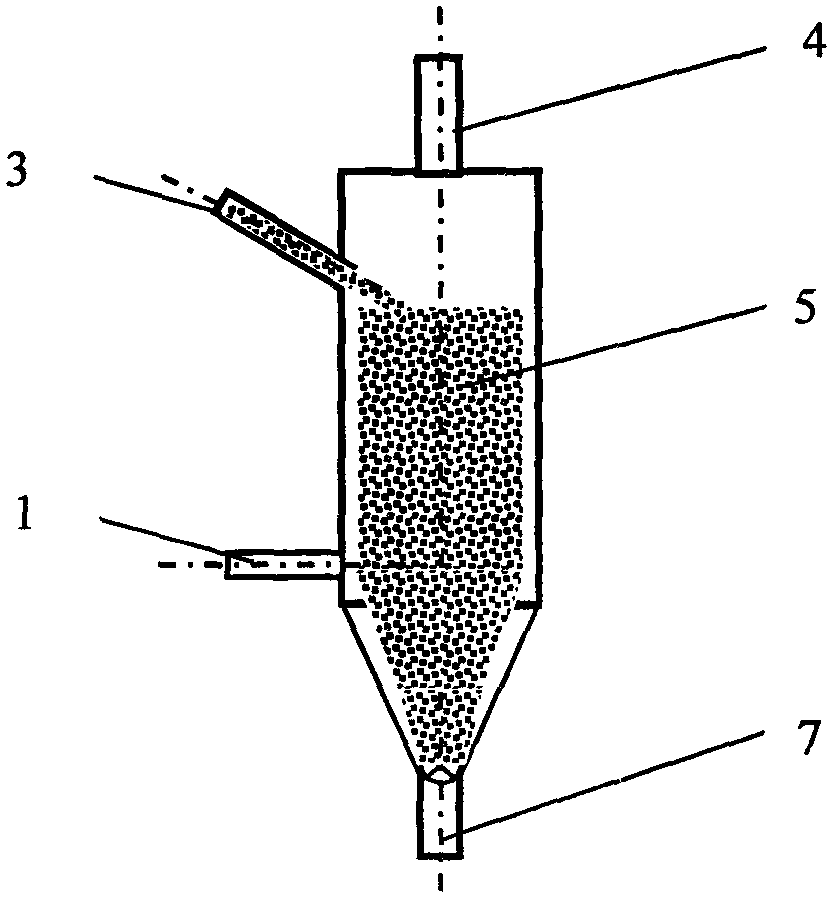

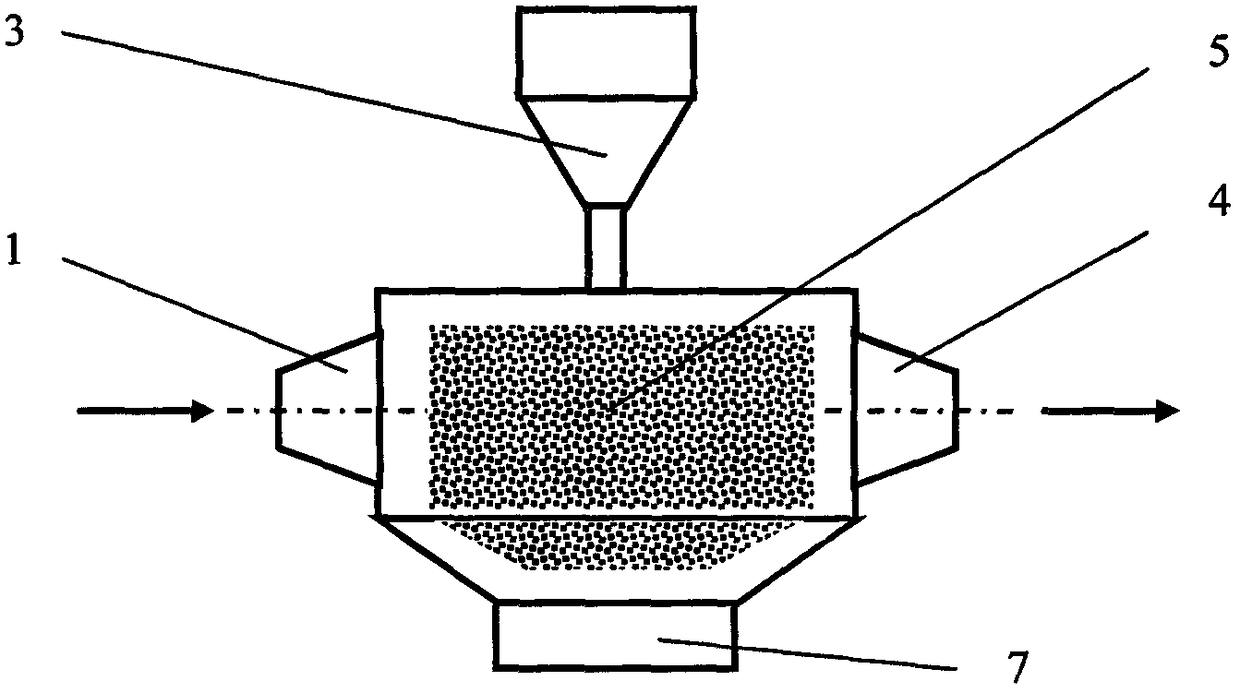

[0018] Embodiment 1: the device of the purifying method of smoke in a kind of moving bed airflow of the present invention is as figure 1 shown. The device is made of stainless steel, and the device is a rectangular cylinder with a size of about 500 × 350 × 1500 (length × width × height, the unit is mm, the same below), and the rotary chain grate is similar to the boiler grate. Structure, there are ventilation gaps evenly distributed on the grate, which is convenient for air flow. The solid material is made of hollow stainless steel balls, the outer diameter is about Φ25, and the material is fed by a conveyor. The stacking height of the hollow stainless steel balls on the grate is about 300, and the gas inlet And the gas outlet diameter is Φ150.

[0019] The treatment process flow is as follows: the smoke-containing gas flow is introduced into the device from the gas inlet (1), passes through the gas-solid contact zone (5) after passing through the gas distributor (2) and the ...

Embodiment 2

[0021] Example 2: The exhaust gas containing soot is the exhaust gas produced by the high-temperature setting machine for textile printing and dyeing fabrics, and the main pollutant is particulate matter of about 150mg / m 3 , the oil fume concentration is about 300mg / m 3 . Gas flow is about 100m 3 / h, the waste gas flow gas inlet is about 150°C, the humidity is about 85%, and other conditions are the same as in Example 1. Experimental results The experiment shows that the moisture in the gas outlet airflow is reduced by about 30%, and the oil fume concentration in the airflow is about 100mg / m 3 , the concentration of solid particles is about 70mg / m 3 .

Embodiment 3

[0022] Example 3: The exhaust gas containing soot in this example is the exhaust gas produced by the metal smelting and quenching production process, and the main pollutant is solid particulate matter with a concentration of about 150 mg / m 3 , the average soot concentration is about 500mg / m 3 . Gas flow is about 50m 3 / h, the gas inlet of the waste gas flow is about 60°C, the humidity is about 70%, and the temperature of the solid material before the hollow stainless steel ball is fed is about 20-25°C. Other conditions are with embodiment 1. Experimental results The experimental results show that the concentration of soot in the gas outlet airflow is about 150mg / m 3 , the concentration of solid particles is about 50mg / m 3 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com