A kind of preparation method of sulfur carbon-based solid acid catalyst

A solid acid catalyst, sulfur-carbon-based technology, applied in chemical instruments and methods, physical/chemical process catalysts, chemical/physical processes, etc. Less problems, etc., to achieve the effect of improved catalytic effect, enhanced acid strength, and high catalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0031] The preparation method of the sulfur-carbon-based solid acid of the present invention has a carbonization process, which mixes a carbon source and a sulfur source for heating and carbonization; and a sulfonation process, which combines the sulfur-containing carbon carrier obtained through the carbonization process with a concentrated At least one of the group consisting of sulfuric acid, oleum, sulfur trioxide and chlorosulfonic acid is sulfonated, and the sulfur-carbon-based solid acid catalyst of the present invention and the preparation methods of these substances are described in detail below.

[0032] The raw material of the sulfur-carbon-based solid acid of the present invention is the carbon source and the sulfur source. As long as at least a part of it is heated to form a carbon layer structure, the sulfonic acid group can be introduced, and there is no special limitation on the carbon source. In the carbon-based solid acid of the present invention Among solid ac...

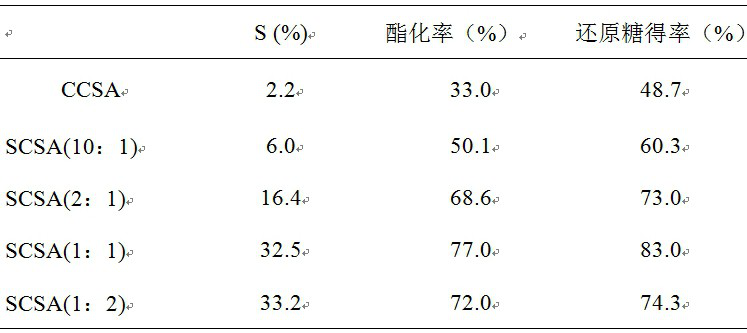

Embodiment 1

[0041] After mixing the cellulose and sulfur uniformly according to a certain ratio of 10:1, weigh a certain mass of the mixture and carbonize it at 440°C under nitrogen to obtain a black solid which is the sulfur-containing carbon carrier; : 1 mass ratio, after sulfonation in oil bath at 150°C for 6 hours, after cooling, washing, filtering, and drying, sulfur carbon-based solid acid is obtained; the sulfur content is 6.0% through analysis, and sulfur carbon is obtained through analysis In addition to the sulfonic acid group in the structure of the thiocarbon-based solid acid, the thiocarbon-based solid acid generally contains S=O, C-S-C and O=S=O. In a reactor with a condensation reflux device, the thiocarbon-based solid acid and methanol According to the ratio of 1g:5ml, react in a heating device with a constant speed magnetic stirring device, and react at a temperature of 70°C for 2 hours, and the conversion rate of oleic acid is calculated to be 50.1%; then take quantitativ...

Embodiment 2

[0043] After mixing cellulose and sulfur uniformly according to a certain ratio of 2:1, weigh a certain mass of the mixture and carbonize it at 440°C under nitrogen to obtain a black solid that is the sulfur-containing carbon carrier; : 1 mass ratio, after sulfonation at 150°C for 6 hours, cooling, washing, filtering, and drying, the sulfur-carbon-based solid acid is obtained; the sulfur content is 16.4% as determined by the sulfur analyzer, and is obtained by XRS analysis. In addition to the sulfonic acid group in the structure of the thiocarbon-based solid acid, the structure of the thiocarbon-based solid acid has O=S=O, C-S-C, S-S. In a reactor with a condensing reflux device, the thiocarbon-based solid acid and methanol According to the ratio of 1g:5ml, react in a heating device with a constant speed magnetic stirring device, and react at a temperature of 70°C for 2 hours, and the conversion rate of oleic acid is calculated to be 68.6%; then, take quantitative cellulose and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com