3D printing special alloy powder and preparing method thereof

An alloy powder and 3D printing technology, applied in the field of 3D printing, can solve the problems that restrict the promotion and popularization of 3D metal forming technology, the powder shape is uncontrollable, and the powder quality is uncontrollable, so as to improve the physical and chemical properties and surface finish. , Improve the effect of powder purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0019] The invention provides a preparation method of 3D printing special alloy powder, comprising the following steps:

[0020] Mix tungsten carbide powder, cobalt powder, chromium powder, aluminum powder and titanium powder and then ball mill to obtain mixed metal powder;

[0021] The mixed metal powder is subjected to induction plasma spheroidization treatment to obtain 3D printing special alloy powder.

[0022] Preferably, the ion gas source of the induction plasma spheroidization treatment is Ar and H 2 ,.

[0023] In the present invention, tungsten carbide powder, cobalt powder, chromium powder, aluminum powder and titanium powder are mixed and ball milled to obtain mixed metal powder; in the present invention, the tungsten carbide powder, cobalt powder, chromium powder, aluminum powder and titanium powder The independent particle size is preferably 1 to 10 μm, more preferably 2 to 8 μm, and most preferably 4 to 6 μm.

[0024] In the present invention, the mass ratio ...

Embodiment 1

[0036] 60 parts by weight of Co powder, 32 parts by weight of Cr powder, 7 parts by weight of Al powder, 1 part by weight of Ti powder, 1900 parts by weight of WC powder and 8000 parts by weight of water wet Mixed by ball milling for 32 hours, in the spray drying tower, carry out spray drying under the pressure of 0.8MPa (the inlet temperature of the spray drying tower is 180 ℃, the temperature of the outlet is 120 ℃), and the obtained particle size is 2 μm Mix metal powder left and right;

[0037] Using Ar and H 2 It is the plasma gas source, the circulating Ar is the quenching gas, the power is 45kw, and the powder feeding rate is 5Kg / h. Print special alloy powder;

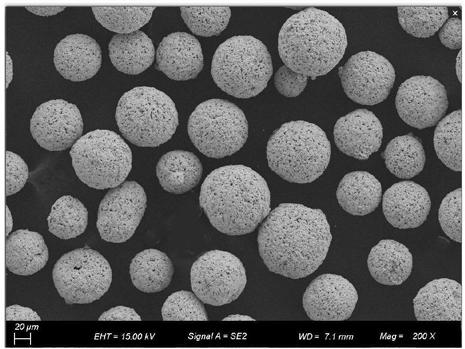

[0038] figure 1 It is the SEM image of the 3D printing special alloy powder. It can be seen from the figure that the alloy powder of the present invention has a spherical shape and a small particle size after spheroidization treatment.

Embodiment 2

[0040] 50 parts by weight of Co powder, 38 parts by weight of Cr powder, 10 parts by weight of Al powder, 2 parts by weight of Ti powder, 1900 parts by weight of WC powder and 8000 parts by weight of water wet Mixed by ball milling for 36 hours, in the spray drying tower, carry out spray drying under the pressure of 1.0MPa (the inlet temperature of the spray drying tower is 200 ℃, the temperature of the outlet is 120 ℃), and the obtained particle size is 2 μm Mix metal powder left and right;

[0041] Using Ar and H 2 It is the plasma gas source, the circulating Ar is the quenching gas, the power is 45kw, and the powder feeding rate is 5Kg / h. Print specialty alloy powders.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com