Method for preparing sulfoxide chloride from industrial chloride salt

A technology of thionyl chloride and chloride salt, applied in chemical instruments and methods, alkali metal sulfite/sulfite, inorganic chemistry, etc., can solve the large gap between supply and demand, the production capacity of thionyl chloride cannot be satisfied, etc. problems, to achieve the effect of facilitating circulation and transportation, realizing circular economy and large industrial value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] Get multi-effect sodium chloride (containing 0.12 organic matter) 18.43g in reaction unit, make its temperature maintain on 105 ℃ with oil bath unit, then slowly add 99.9% sulfur trioxide in reaction unit, the addition rate of sulfur trioxide is with The temperature rise of the material in the reaction device is not obvious. The average adding rate of sulfur trioxide in the laboratory is 0.5g / min. Stir the reaction. When the sulfur trioxide is added, the qualified intermediate material can be obtained. Intermediate material sodium chlorosulfonate 43.58g. According to the mass balance calculation, the added sulfur trioxide mass is 25.17g.

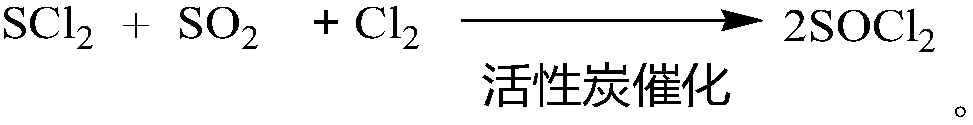

[0047] Then heat the obtained intermediate material to 300°C for cracking reaction, add 16.20g of sulfur dichloride to the mixed gas produced in the cracking process, enter the thionyl chloride synthesis device (activated carbon catalysis, reaction temperature 200°C), and the reaction is completed Get the sulfur oxychloride that reac...

Embodiment 2

[0050] Get multi-effect sodium chloride (containing 0.97% organic matter) 18.71g in reaction unit, make its temperature maintain on 150 ℃ with oil bath unit, then slowly add 50.6% sulfur trioxide in reaction unit, the rate of addition of sulfur trioxide Subject to the insignificant temperature rise of the material in the reaction device, the average adding rate of sulfur trioxide in the laboratory is 1.1g / min, and the reaction is stirred. When the sulfur trioxide is added, the qualified intermediate material can be obtained, and the liquid state can be obtained by weighing. The intermediate material sodium chlorosulfonate 43.87g. The mass of sulfur trioxide added according to material balance calculation is 25.34g.

[0051] Then the obtained intermediate material is heated up to 300°C for cracking reaction, the mixed gas produced in the cracking process is added with 16.32g of sulfur dichloride, and enters the thionyl chloride synthesis device (activated carbon catalysis, reac...

Embodiment 3

[0054] Get multi-effect sodium chloride (containing 2.1% organic matter) 18.87g in reaction unit, make its temperature maintain on 180 ℃ with oil bath unit, then slowly add 80% sulfur trioxide in reaction unit, the rate of addition of sulfur trioxide Subject to the insignificant temperature rise of the material in the reaction device, the average adding rate of sulfur trioxide in the laboratory is 0.87g / min, and the reaction is stirred. When the sulfur trioxide is added, the qualified intermediate material can be obtained, and the liquid state can be obtained by weighing. The intermediate material sodium chlorosulfonate 43.75g. According to the material balance calculation, the added sulfur trioxide mass is 25.26g.

[0055] Then the obtained intermediate material is heated up to 300°C for cracking reaction, and 16.26g of sulfur dichloride is added to the mixed gas produced in the cracking process, and enters the thionyl chloride synthesis device (activated carbon catalysis, re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com