Hierarchical-pore EU-1 molecular sieve and preparation method thereof

A EU-1, molecular sieve technology, applied in the direction of molecular sieve catalysts, molecular sieves and base exchange compounds, chemical instruments and methods, etc., can solve problems such as poor hydrothermal stability, fast catalytic reaction deactivation speed, and low molecular diffusion efficiency , to achieve the effect of alleviating the rate of silicon dissolution, retaining the volume of micropores, and increasing the solid yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

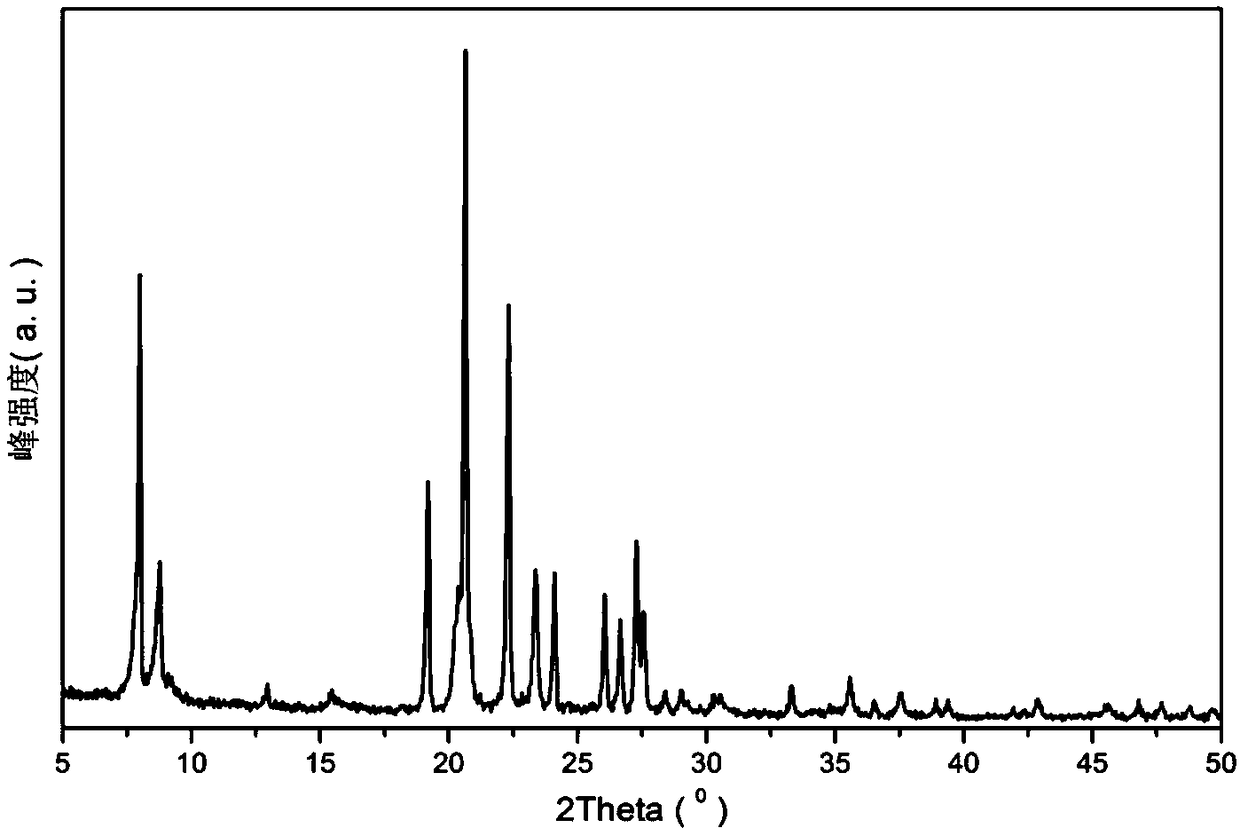

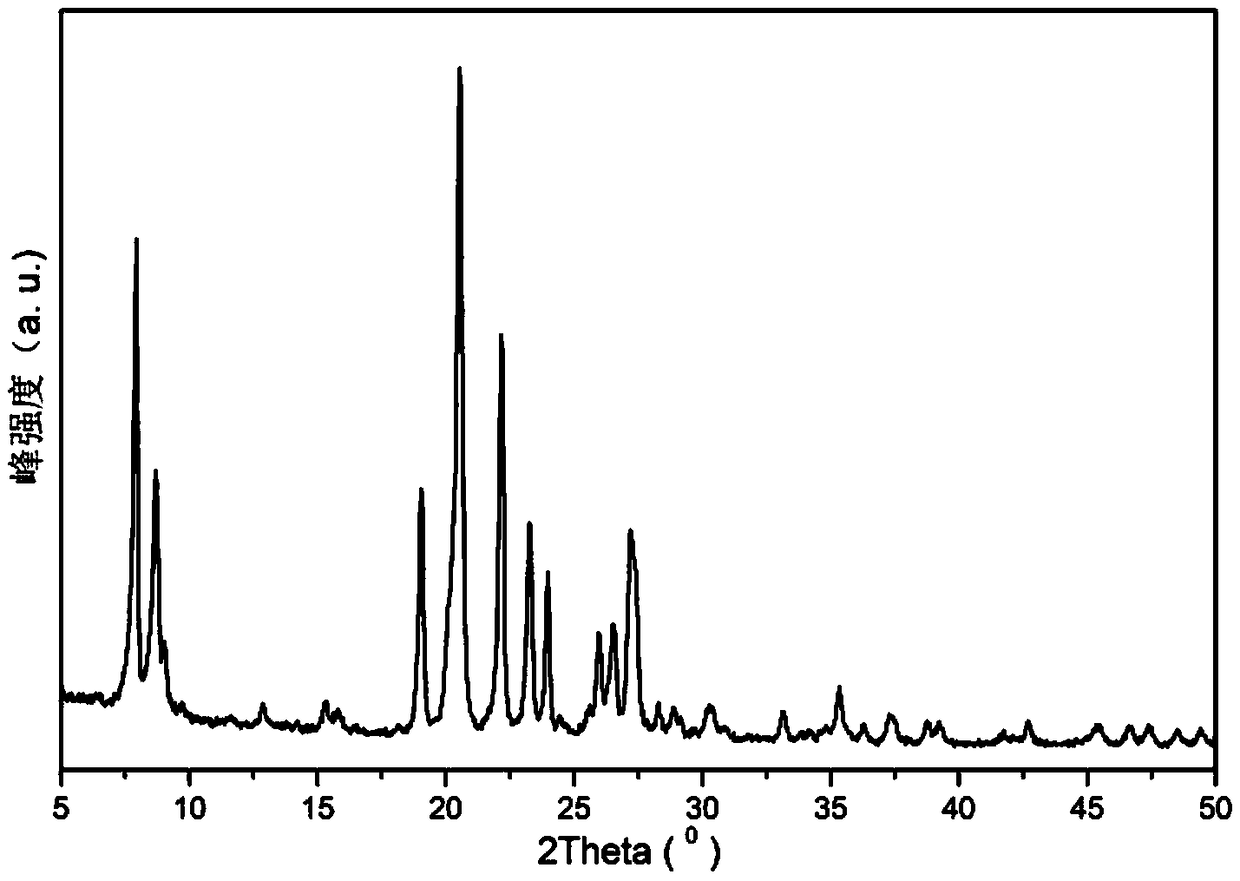

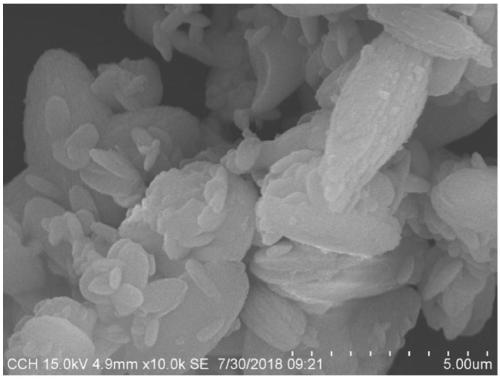

[0033] The EU-1 molecular sieve in Comparative Example 1 was used as the original powder, and the original powder was placed in a mixed alkaline solution formed by 0.08mol / L NaOH and piperazine, and treated with alkali at room temperature for 10 minutes, and the solid-liquid mass ratio was 1:20. SiO in Piperazine and EU-1 Molecular Sieve Raw Powder 2 The molar ratio is 0.02:1. Then add 0.4mol / L citric acid to the system to adjust the pH to neutral, filter out the solid, wash the solid with deionized water until it is neutral, and then dry it at 120°C for 12 hours; the dried solid is then placed in a 0.5mol / L The citric acid solution was refluxed at 120°C for 10 hours, and the solid-to-liquid mass ratio was 1:10; then the solid product was filtered out, and the solid product was deionized and washed to neutrality, and then dried at 120°C for 12 hours to obtain hierarchically porous EU -1 molecular sieve. figure 2 Explain that the obtained product is an EUO topological struct...

Embodiment 2-8

[0035] The preparation method of Examples 2-8 is basically the same as that of Example 1, the type of inorganic lye used, the type of piperidine compounds, the treatment time of molecular sieves in lye, the type of acid, the acid concentration, the mass ratio of solid to acid solution, and the reflux Each parameter such as temperature and time is different, as shown in table 1 and table 2; Nitrogen physical adsorption result shows, the sample that embodiment 1-8 obtains all contains mesopore structure, mesopore diameter distribution, average pore diameter and mesopore The pore volume is shown in Table 3:

[0036] Table 1

[0037]

[0038] Table 2

[0039]

[0040] *: product solid yield% = multi-level porous EU-1 molecular sieve product mass / initial EU-1 molecular sieve mass × 100%

[0041] table 3

[0042]

[0043]

[0044] It can be seen from Table 3 that the molecular sieves synthesized in the examples of the present invention have mesoporous structures of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| crystallinity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com