Production method and production system of high-purity polyaluminum sulfate chloride

A polysulfide aluminum chloride, production system technology, applied in chemical instruments and methods, aluminum sulfur compounds, chemical industry and other directions, can solve the problems of low utilization rate of raw materials, long production cycle, low product qualification rate, etc., to avoid heating The effect of cooling process, simple structure and high purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

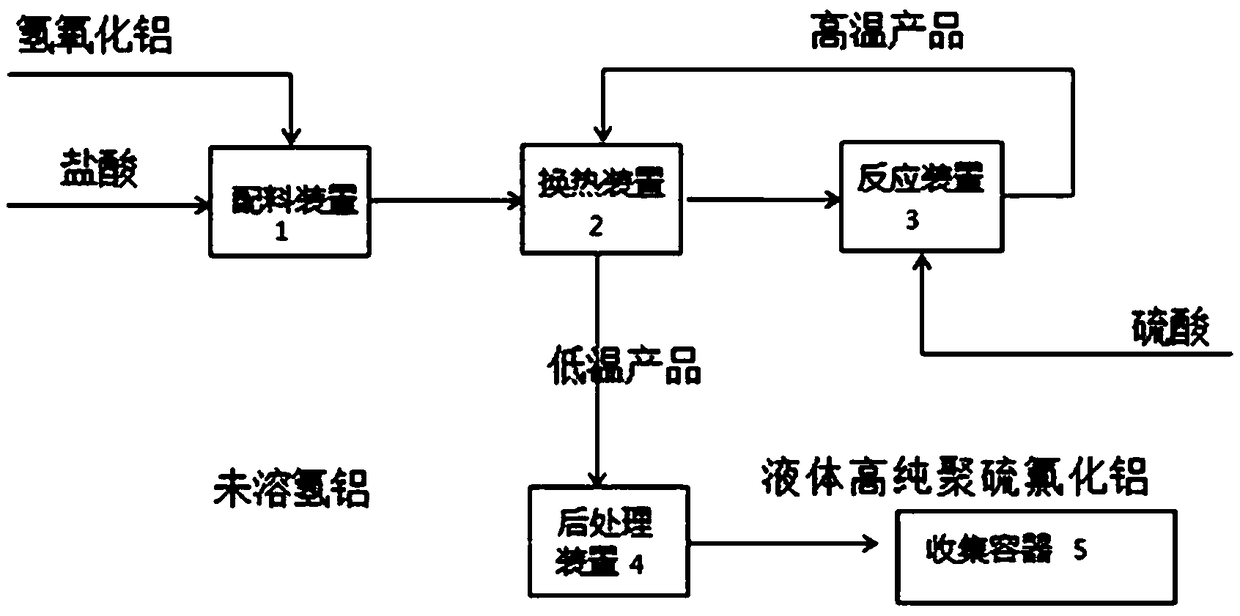

[0047] A kind of production method of high-purity polyaluminum sulfide chloride of the present invention adopts above-mentioned production system, comprises the following steps:

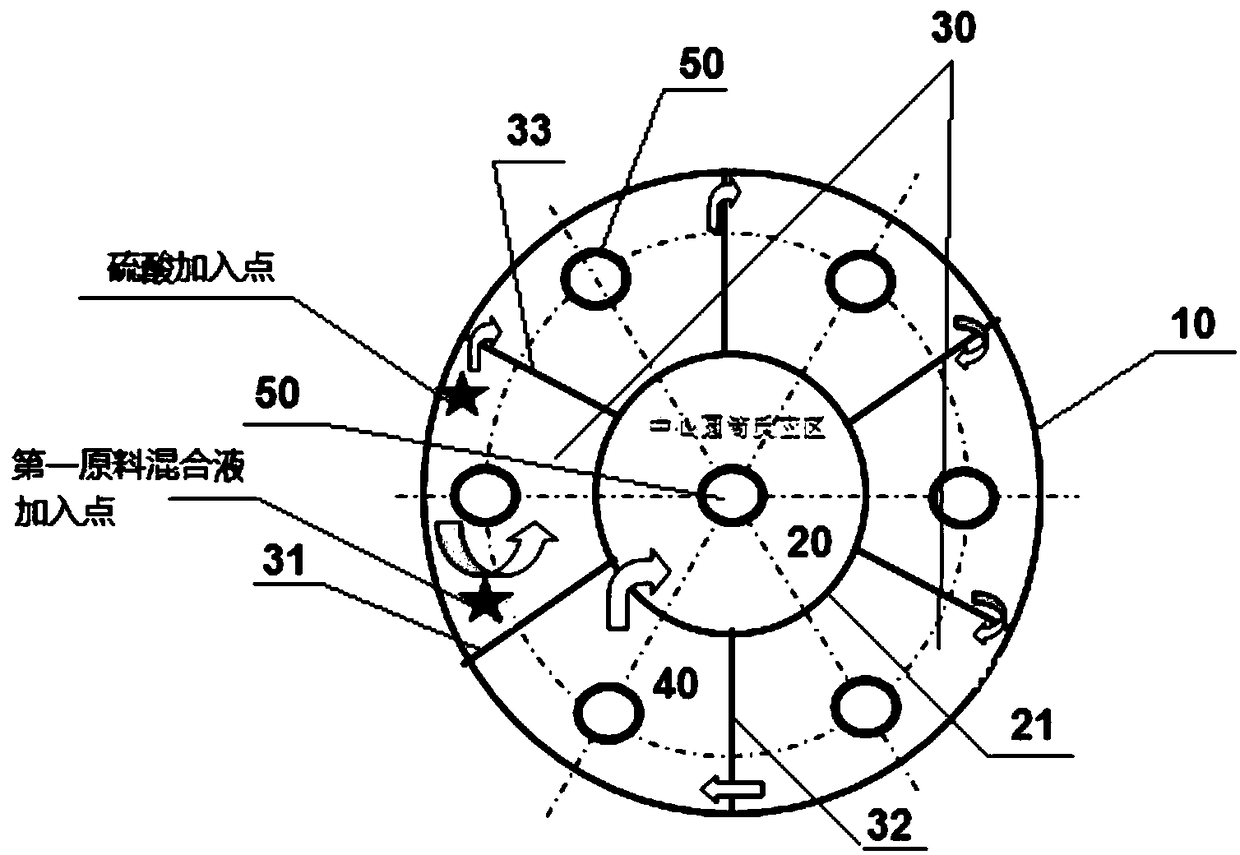

[0048] Step 1, 3000 kg containing Al 2 o 3 60% industrial aluminum hydroxide (wet powder) and 5350 kilograms of 31% synthetic hydrochloric acid are added to the batching device respectively, and mixed uniformly to obtain the first raw material mixture (hot high-purity polyaluminum chloride product), which is passed through the heat exchange device. The pipeline is input to the reaction zone next to the first dividing plate 31 in the reaction part-30 of the reaction device (8000 liters of glass-lined reactor);

[0049] Step 2, add 630 kilograms of 98% sulfuric acid to the reaction zone next to the first dividing plate 31 in the reaction part one 30;

[0050] Step 3, heating the reaction device to the temperature required for the reaction, pressurizing, and carrying out the chemical reaction, the exo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com