Yttrium aluminum silicate glass ceramic containing Y4.67(SiO4)3O apatite crystalline phase and preparation method thereof

A technology of silicate glass and glass ceramics, which is applied in glass manufacturing equipment, glass furnace equipment, glass forming and other directions, and achieves the effects of simple preparation process, simple operation and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0027] The invention provides a preparation method of yttrium aluminum silicate glass ceramics, comprising the following steps:

[0028]S1: Mix the raw material components evenly in proportion, then place them in a quartz crucible or a corundum crucible, put them into a silicon-molybdenum furnace, raise the temperature to 1450-1850°C to melt the raw materials into a liquid state, and heat them at a temperature of 1450-1850°C Constant temperature for 1-4 hours; then pour the molten liquid in the crucible onto the preheated graphite abrasive tool to solidify and form, quickly put it into a box furnace at 700-900°C, keep it warm for 1-2 hours, and drop to room temperature with the furnace to obtain Clear yttrium aluminum silicate glass. Wherein, each raw material component is mixed according to the following ratio: Y 2 o 3 48-60 parts by mass, Al 2 o 3 8 to 30 parts by mass and SiO 2 23 to 30 parts by mass.

[0029] S2: Obtain the glass transition temperature and crystal...

Embodiment 1

[0033] This embodiment provides a method for preparing yttrium aluminum silicate glass ceramics, comprising the following steps:

[0034] S1: 49% Y by mass percentage 2 o 3 , 23%Al 2 o 3 and 28% SiO 2 Weigh each component, mix the above components fully and evenly, place them in a corundum crucible, put them into a silicon-molybdenum furnace, raise the temperature to 1580°C, melt the raw materials into a liquid state, and keep the temperature at 1580°C for 3 hours, put the crucible The liquid in it was poured on the preheated graphite abrasive tool to solidify and formed, then quickly put it into a box furnace at 800°C, keep it warm for 2 hours, and then lowered to room temperature with the furnace to obtain transparent yttrium aluminosilicate glass.

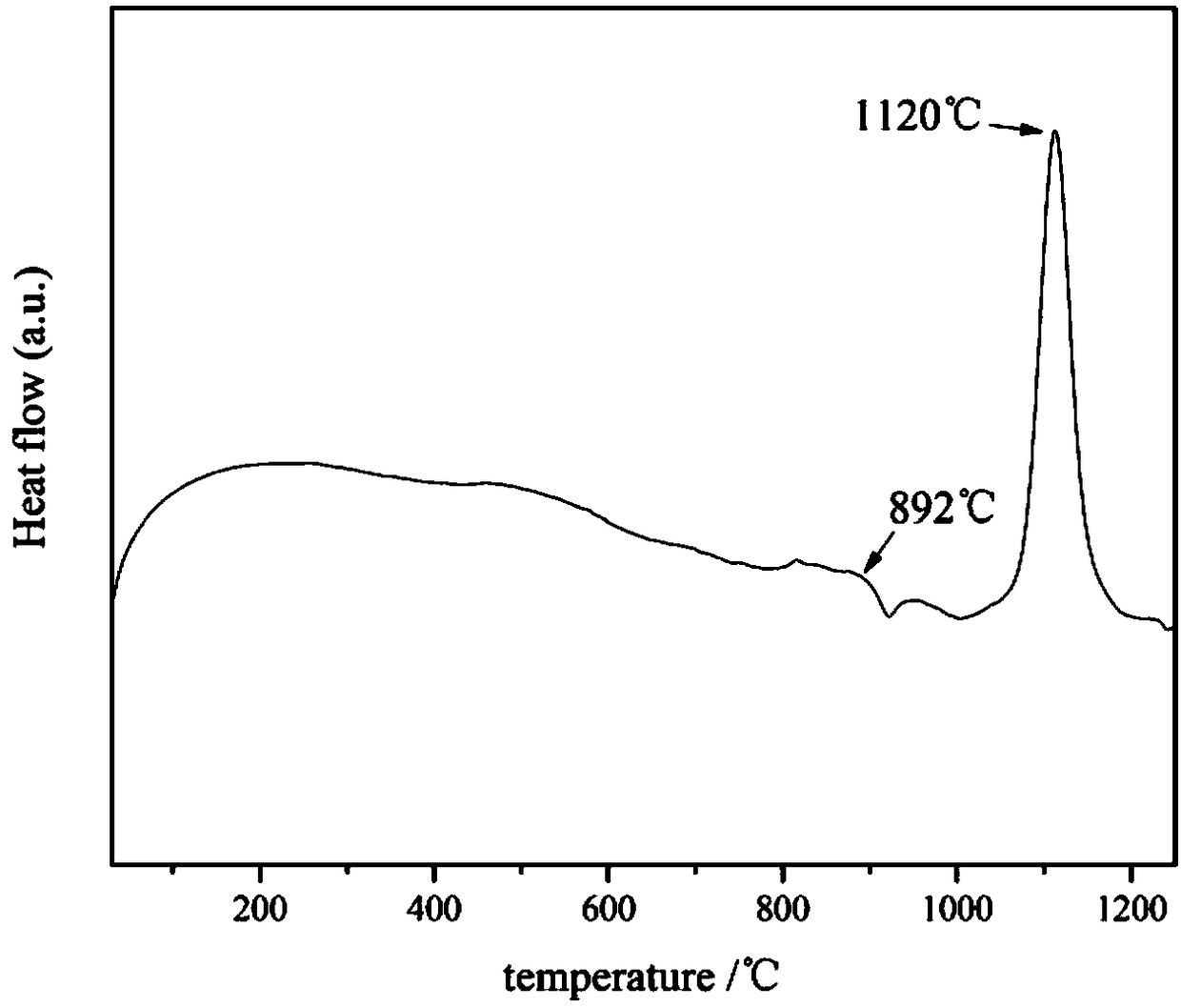

[0035] S2: Obtain the glass transition temperature and crystallization peak temperature of the glass by differential scanning calorimetry, such as figure 1 As shown, the following crystallization heat treatment system was w...

Embodiment 2

[0038] This embodiment provides a method for preparing yttrium aluminum silicate glass ceramics, comprising the following steps:

[0039] S1: 52% Y by mass percentage 2 o 3 , 21%Al 2 o 3 and 27% SiO 2 Weigh each component, mix the above components fully and evenly, place in a corundum crucible, put it into a silicon molybdenum furnace, raise the temperature to 1600°C, melt the raw materials into a liquid state, and keep the temperature at 1600°C for 3 hours, put the crucible The liquid in it was poured on the preheated graphite abrasive tool to solidify and formed, then quickly put it into a box furnace at 800°C, keep it warm for 2 hours, and then lowered to room temperature with the furnace to obtain transparent yttrium aluminosilicate glass.

[0040] S2: The glass transition temperature and crystallization peak temperature of the glass are obtained by differential scanning calorimetry, and the following crystallization heat treatment system is formulated; the transparent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com